Manufacturing process of photosensitive resin eyeglasses

A photosensitive resin and manufacturing process technology, applied in optics, optical components, optical components, etc., can solve the problems of passive capital turnover, backlog of inventory, difficult to change degree, etc., and achieve the effect of rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

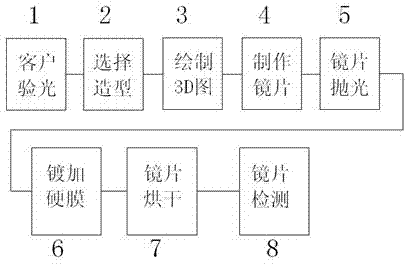

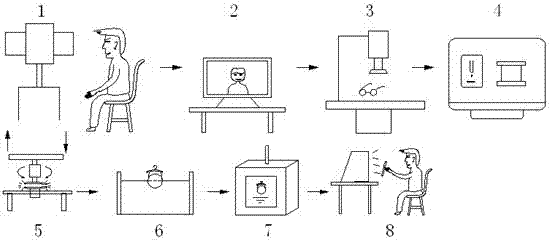

[0018] refer to figure 1 , figure 2 , a manufacturing process and method of a personalized customized photosensitive resin lens of the present invention includes customer optometry 1, selecting lens shape 2, scanning and drawing 3D picture 3, making lens 4, lens polishing 5, coating and adding hard film 6, lens drying 7. Lens inspection 8 has a total of eight processes, the specific steps are as follows:

[0019] 1. Customer optometry: first conduct optometry for customers who need customized glasses, obtain optometry data, and fill in the optometry form;

[0020] 2. Choose the shape of the lens: let the customer choose the style of the glasses and the appearance of the lens on the computer;

[0021] 3. Scanning and drawing 3D diagrams: hand over the glasses and optometry sheets selected by the customer to the drawing staff to draw 3D model processing diagrams;

[0022] 4. Manufacture of lenses: Use American Fortusmc series rapid prototyping equipment with transparent phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com