Light-emitting element mounting substrate and LED package

A technology for light-emitting components and substrates, applied in electrical components, semiconductor devices, electric solid-state devices, etc., can solve the problems of difficulty in obtaining heat dissipation, loss of competitiveness, and high prices, and achieve the effect of excellent heat dissipation and light reflectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

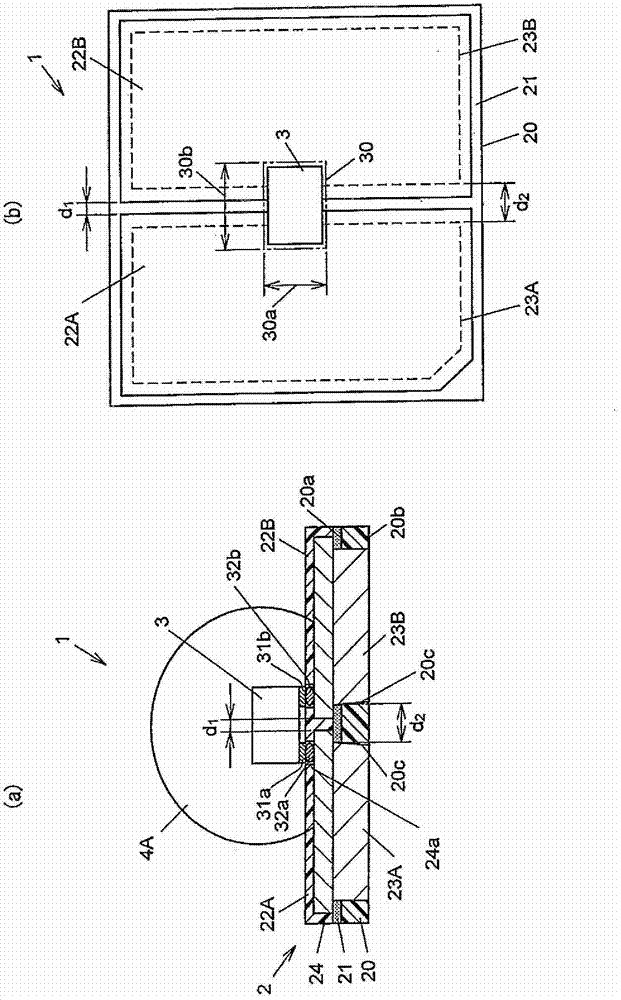

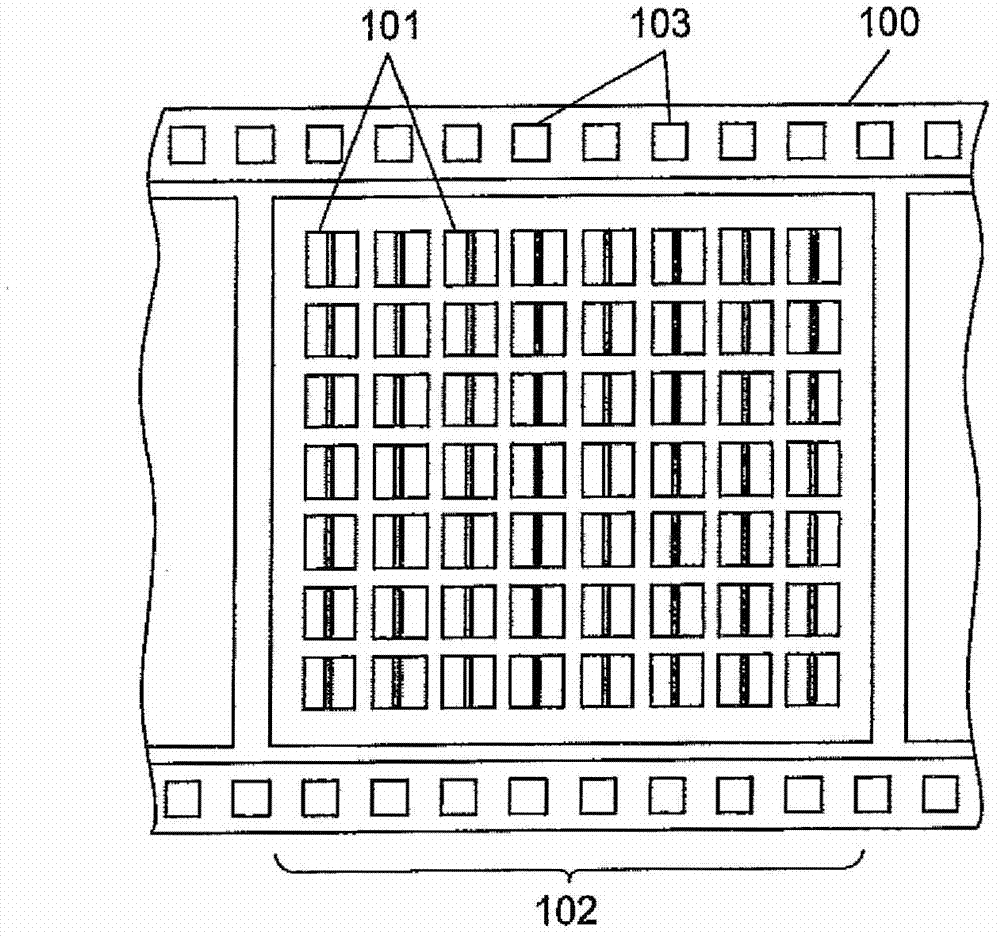

[0046] Figure 1A (a) is a cross-sectional view of the LED package according to the first embodiment of the present invention, Figure 1A (b) is from Figure 1A (a) Top view of the LED package with the sealing resin and insulating layer removed. Figure 1B (c) is a plan view of a substrate for mounting a light emitting element.

[0047] An LED package 1 as an example of a light emitting element such as Figure 1A As shown in (a) and (b), in the mounting region 30 of the pair of wiring patterns 22A, 22B of the light-emitting element mounting substrate 2, a flip-chip LED chip having electrodes 31a, 31b on the bottom surface as a light-emitting element is placed. 3 Perform flip-chip connection by bumps 32a and 32b, and seal the LED chip 3 with the sealing resin 4A.

[0048] The light-emitting element mounting substrate 2 is a so-called single-sided wiring board having wiring on one side of the substrate, and includes: a resin film 20 as a substrate having insulating properties; ...

no. 2 approach

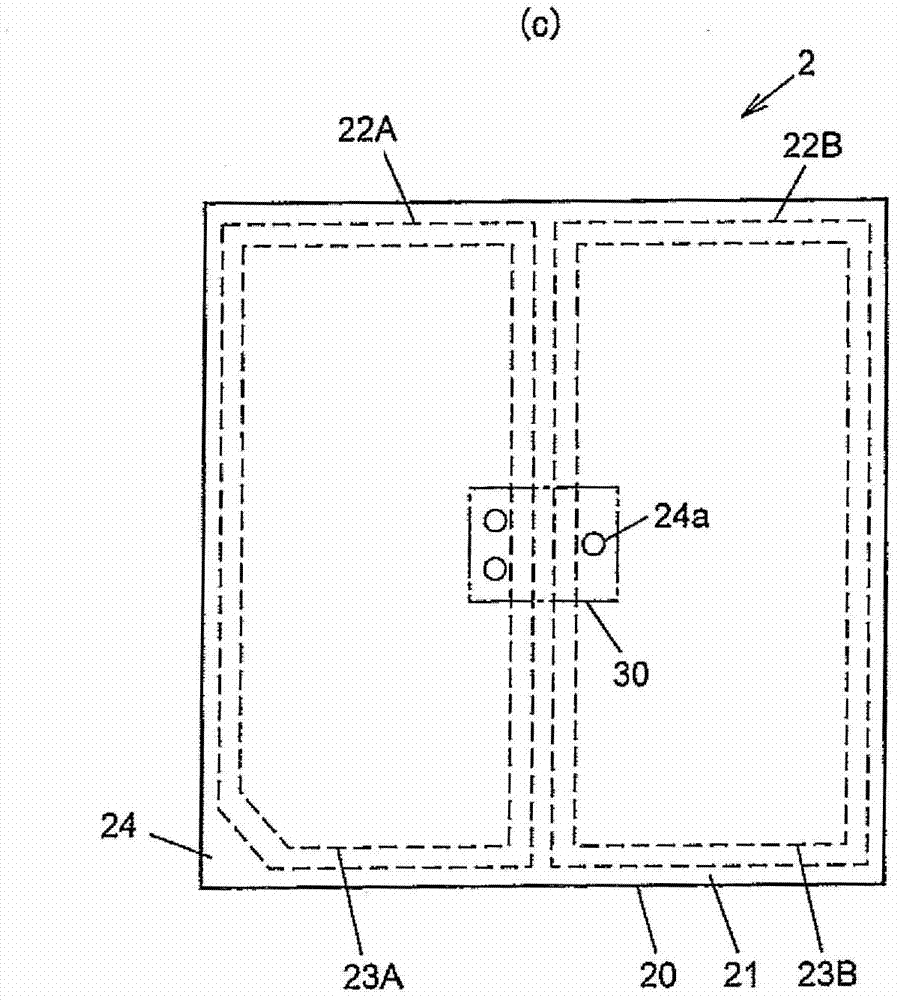

[0120] Figure 4 (a) shows the LED package according to the second embodiment of the present invention, and is a plan view of the LED package with the sealing resin and insulating layer removed, Figure 4 (b) is a plan view of a substrate for mounting a light emitting element.

[0121] In the first embodiment, one LED chip 3 is mounted on the substrate 2 for mounting a light-emitting element, and the LED package 1 of this embodiment is as follows: Figure 4 As shown in (a), a plurality of (for example, three) LED chips 3 are mounted.

[0122] The mounting area 30 of this embodiment is an area including three LED chips 3 . The pair of wiring patterns 22A, 22B has a first distance d1 between the length of one side 30 a of the mounting region 30 , for example, 1.5 mm or more, and the length of one side 30 b of the mounting region 30 , for example, 0.04 mm or less.

[0123] The pair of filling portions 23A, 23B has a second distance d2 of, for example, 0.02 mm or less, within t...

no. 3 approach

[0126] Figure 5 (a) shows the LED package according to the third embodiment of the present invention, and is a plan view of the LED package without the sealing resin and the insulating layer, Figure 5 (b) is a plan view of a substrate for mounting a light emitting element.

[0127] In the first and second embodiments, there was only one mounting area 30 and only the flip-chip LED chip 3 was mounted. However, the present embodiment has a plurality of mounting areas 30A, 30B, and in addition to the LED chip 3, there are also Equipped with other electronic components.

[0128] That is, the LED package 1 of the present embodiment is as Figure 5 As shown in (a), a mounting region 30A is provided across a pair of wiring patterns 22A and 22B, and a mounting region 30B is also provided on one wiring pattern 22A. This LED package 1 mounts the same flip-chip LED chip 3 as in the first and second embodiments on one mounting area 30A, and mounts a wire-bonding LED chip 5A on the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com