Manufacturing method of shell of motor stator

A motor stator shell and manufacturing method technology, applied in the manufacture of stator/rotor bodies, motor generators, electrical components, etc., can solve the problems of affecting the transmission of magnetic fields between stators and rotors, high production costs, and poor performance of motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below with reference to the embodiments given in the accompanying drawings.

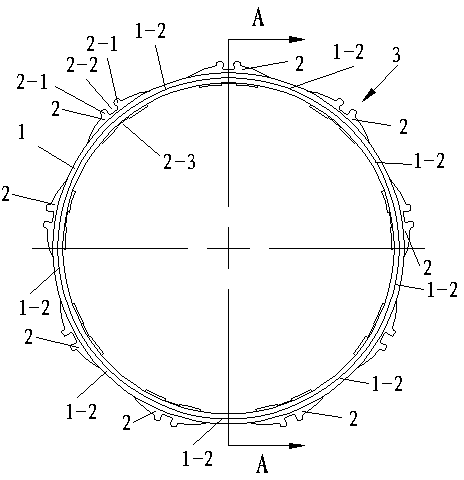

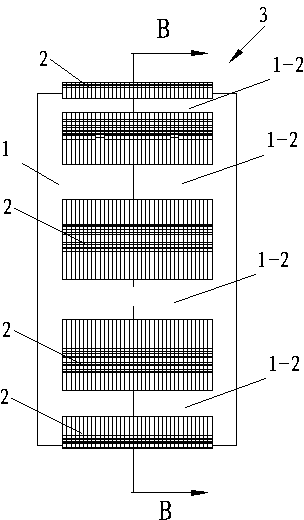

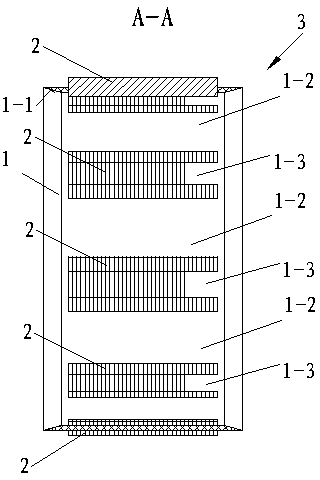

[0021] see figure 1 , 2 , 3, 4, 6, and 7, a method for manufacturing a stator housing of a motor, comprising the following steps: a. Superimposing and fixing a plurality of silicon steel sheets to form a silicon steel sheet assembly 2,

[0022] b. Injection molding a plurality of silicon steel sheet assemblies 2 with plastic to become a motor stator silicon pole frame 3, the motor stator silicon pole frame 3 includes a plastic annular frame 1 and a plurality of silicon steel sheet assemblies 2, and the plastic annular frame 1 is An integral frame, a plurality of silicon steel sheet components 2 are arranged along the circumferential direction of the plastic ring frame 1, each silicon steel sheet component 2 is fixedly connected with the plastic ring frame 1, and there is a plastic ring frame between adjacent silicon steel sheet compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com