Automatic cutting machine for both ends of laser printer rubber roller

A technology of laser printers and rubber rollers, applied in metal processing, etc., can solve problems such as injury accidents, easy to produce defective products, and slow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

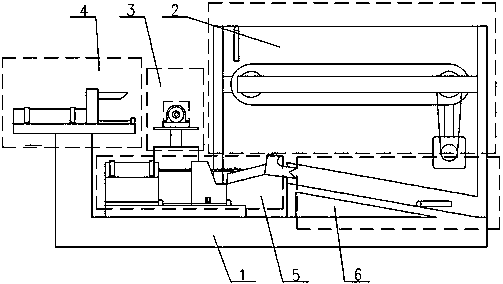

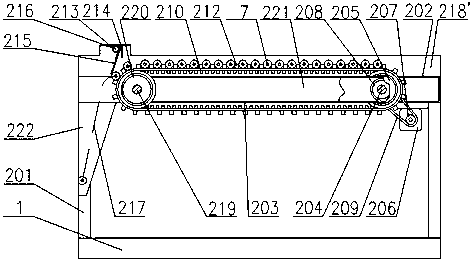

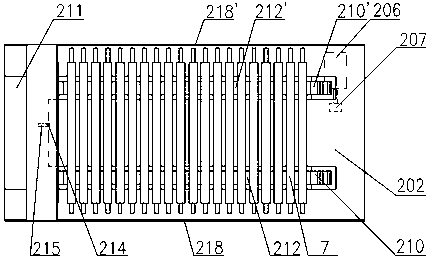

[0039] Such as figure 1 As shown, the present invention includes a base 1, and also includes a cutting device 4, a clamping and rotating device 3, a pick-up device 5, a conveying device 2, and a collection device 6 that are sequentially arranged on the top of the base 1 from left to right; When the slider DF508 is in the left station, the feeding slot 517 of the receiving device 5 is located below the blanking place of the clamping and rotating device 3; when the slider DF508 is in the right station, the feeding slot 517 before cutting is located Below the blanking place of the device 2, while the feeding notch 518 after cutting of the pick-up device 5 is located below the blanking place of the clamping and rotating device 3; The feed notch 517 is located above the feed inlet of the slope 602 of the collecting device 6; after the clamping and rotating device 3 is clamped and raised, the workpiece rubber roller 7 faces the cutting edge of the blade 406 of the cutting device 4 l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com