Circulation gas cooler anti-clogging technology for polyethylene prepared by vapor phase method and device

A technology of polyethylene and circulating gas, which is applied in the field of anti-clogging technology, can solve the problems of fast blockage of the cooler and affect the operation cycle of the device, and achieve the effect of improving production capacity and benefit without affecting product quality and reducing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

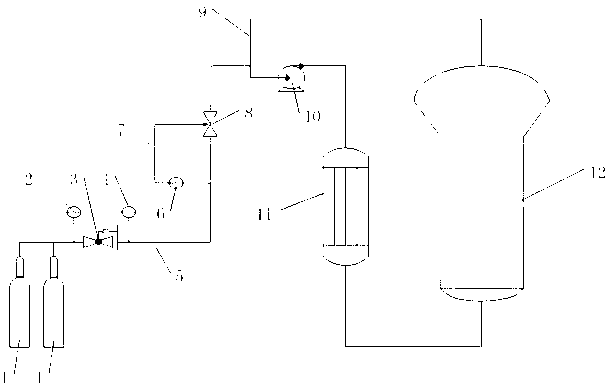

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] The anti-clogging process device of the gas-phase method polyethylene circulation gas cooler, including a high-pressure steel cylinder 1, a decompression device, a metering control device and an oxygen delivery pipeline 5, between the high-pressure steel cylinder 1 and the circulation gas pipeline 9 of the gas-phase method preparation polyethylene device An oxygen delivery pipeline 5 is set, and a decompression device and a metering control device are sequentially arranged on the oxygen delivery pipeline 5 .

[0018] The high-pressure cylinder 1 is used to store the irreversible poison oxygen of the catalyst; the oxygen is 2500ppm standard gas, and the pressure is 4MPa-10MPa.

[0019] The decompression device includes a pre-decompression pressure gauge 2, a decompression valve 3 and a post-decompression pressure gauge 4, which are sequentially arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com