Polyethylene glycol/stannic sulfide intercalation quantum dot and hydrothermal synthesis method

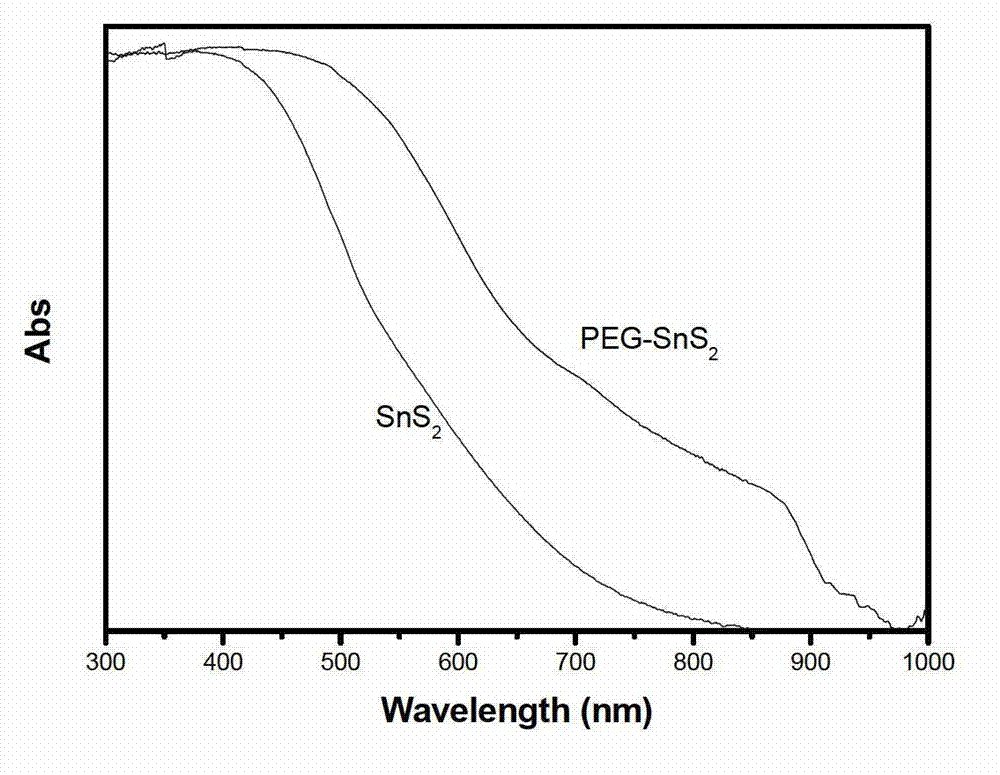

A tin disulfide, polyethylene glycol technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as the properties and application research gaps of polyethylene glycol/tin disulfide intercalation compounds, and achieve excellent single/ The effect of two-photon fluorescence performance, easy operation, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

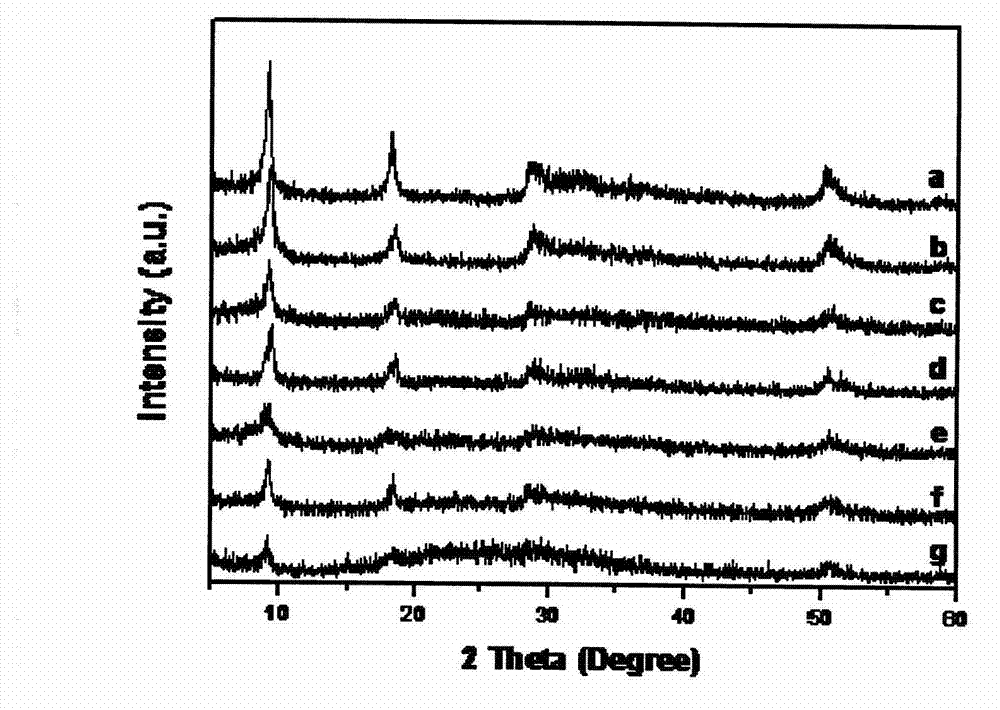

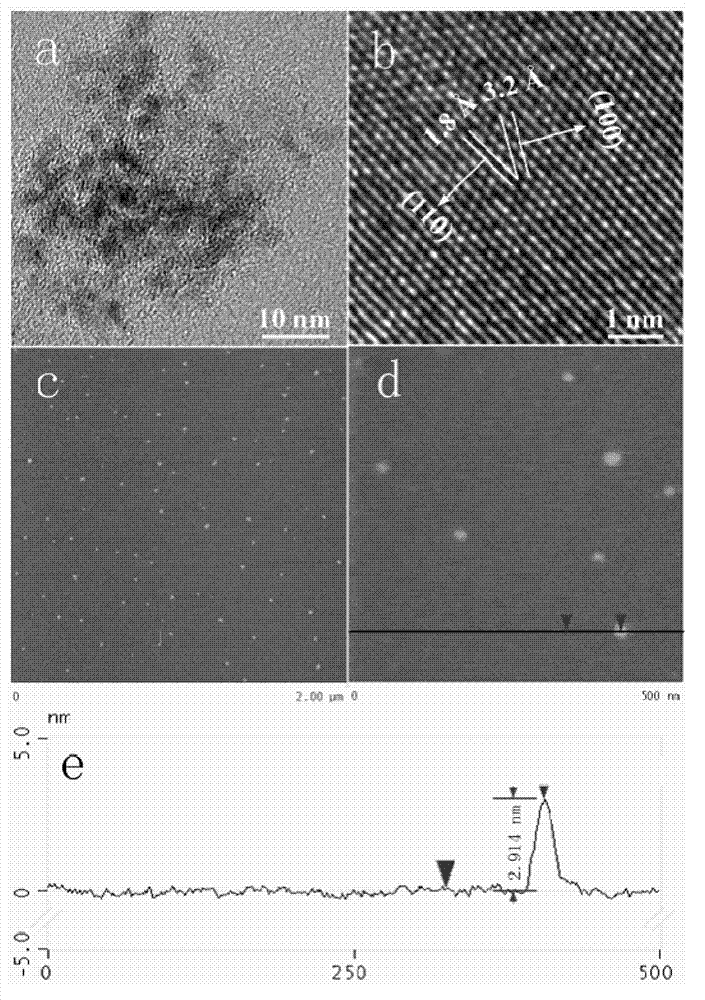

[0036] ①First weigh 2.5mmol polyethylene glycol (0.5g) with a molecular weight of 200, 0.8mmol SnCl 4 ·5H 2 O, 3.2mmol of thioacetamide and 80mL of dilute hydrochloric acid (1mol / L) into a 250mL beaker, and magnetically stirred at room temperature for 30min. The molar ratio of tin salt, sulfur source and polyethylene glycol is 1:4:3.125. The resulting solution was transferred to a 100 mL reactor and reacted at 200°C for 12 hours.

[0037] ②After the reaction, the reaction kettle is naturally cooled to room temperature, and the polyethylene glycol / tin disulfide intercalated quantum dot dispersion can be obtained after filtration; the quantum dot dispersion can be centrifuged and dried to obtain the quantum dot solid powder. The interlayer spacing of the intercalation compound is 0.97 nm, and the fluorescence quantum efficiency of the aqueous quantum dot dispersion is 20%.

Embodiment 2

[0039] The steps are the same as in Example 1, except that the 2.5 mmol polyethylene glycol with a molecular weight of 200 in Example 1 is changed to 1.25 mmol polyethylene glycol with a molecular weight of 400. The molar ratio of tin salt, sulfur source and polyethylene glycol is changed from 1:4:3.125 to 1:4:1.5625. The product is polyethylene glycol / tin disulfide intercalated quantum dots. The intercalation compound has an interlayer spacing of 0.95 nm, and its quantum dot aqueous dispersion has a fluorescence quantum efficiency of 36%.

Embodiment 3

[0041] The steps are the same as in Example 1, except that the 2.5 mmol polyethylene glycol with a molecular weight of 200 in Example 1 is changed to 0.833 mmol polyethylene glycol with a molecular weight of 600. The molar ratio of tin salt, sulfur source and polyethylene glycol is changed from 1:4:3.125 to 1:4:1.0417. The product is polyethylene glycol / tin disulfide intercalated quantum dots. The interlayer spacing of the intercalation compound is 0.95 nm, and the fluorescence quantum efficiency of the aqueous quantum dot dispersion is 38%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com