Multifunctional elasticizer

A texturing machine and multi-functional technology, applied in textiles and papermaking, etc., can solve problems affecting production efficiency, poor functionality, and low product qualification rate, and achieve high production efficiency, good texturing effect, and good product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

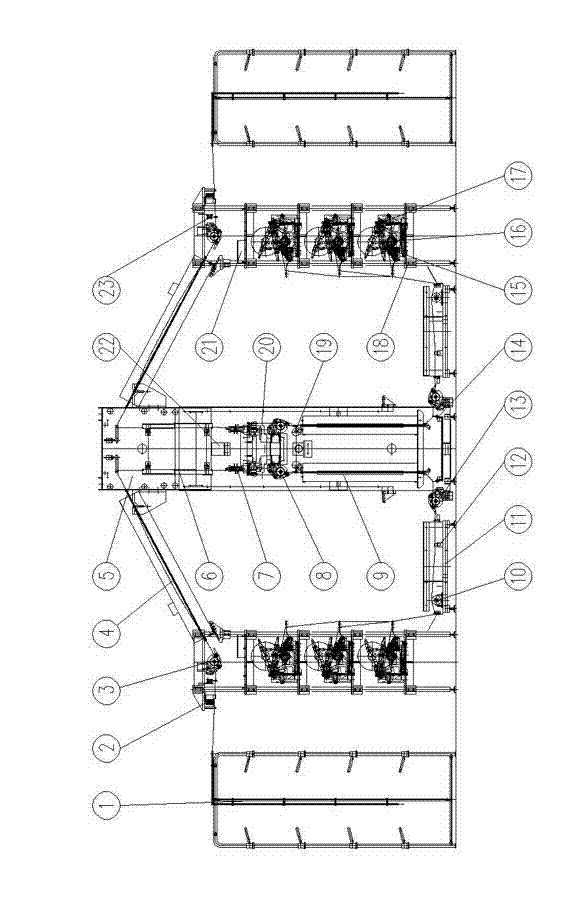

[0017] The implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] like figure 1 As shown, a multi-functional texturing machine is used for processing raw silk into elastic yarn, including a raw silk frame 1, a sub-frame device, a deformation heating box 4, a main frame device and a pedal device. Among them, the sub-frame device includes sub-frame 18, shredder 2, I roller wire moving 23, I roller 3, fixed length 21, bobbin rack 17, friction roller 16 and groove box 15, and the main frame device includes the main machine Frame 5, cold rail 6, wire groove 22, false twister 7, II roller wire transfer 20, II roller 8, network 19, shaping heating box 9, III roller wire transfer 14, and III roller 13, and the foot board device includes the foot board 11. Oiling part 10 and thread finder 12.

[0019] In this embodiment, the multifunctional texturing machine is arranged symmetrically with respect to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com