Brick Concrete Reinforced Structure of Seismic Isolation Bearing and Its Installation Underpinning Method

A technology for seismic isolation bearings and reinforced structures, which is applied in the direction of basic structure engineering, earthquake resistance, building components, etc., can solve the problems affecting the quality control of seismic isolation reinforcement, the difficulty of concrete construction, and the extension of construction period, etc., to achieve the solution of installation underpinning Problems, fast construction, good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

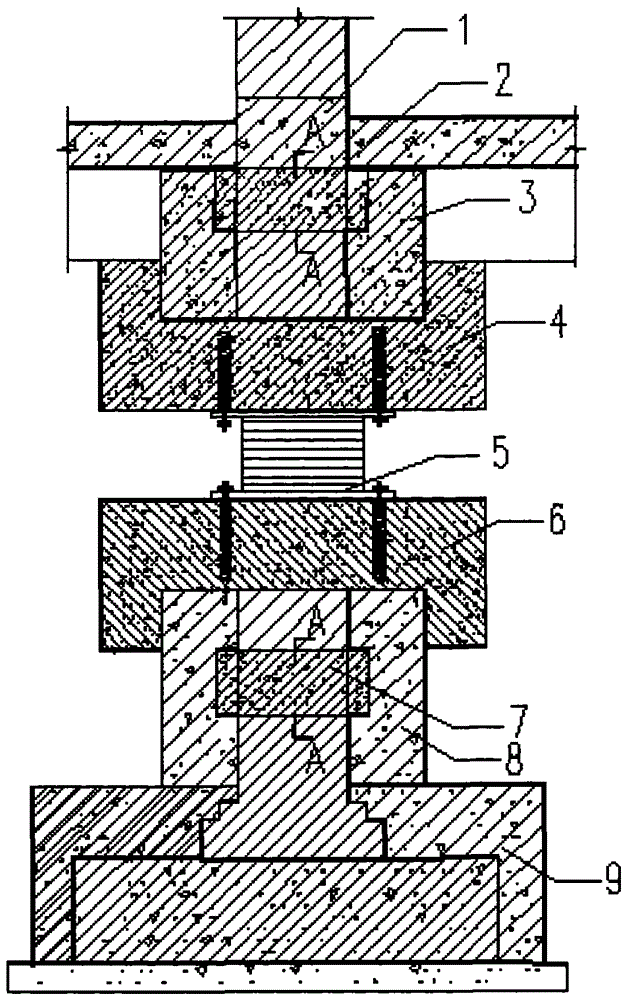

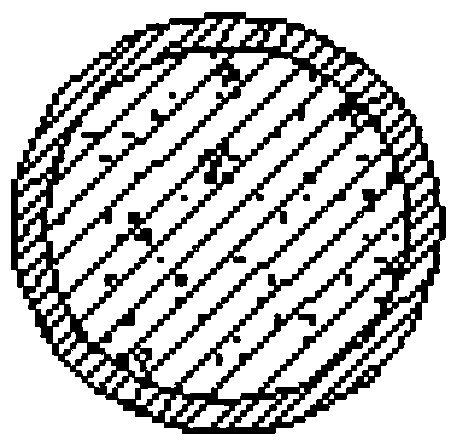

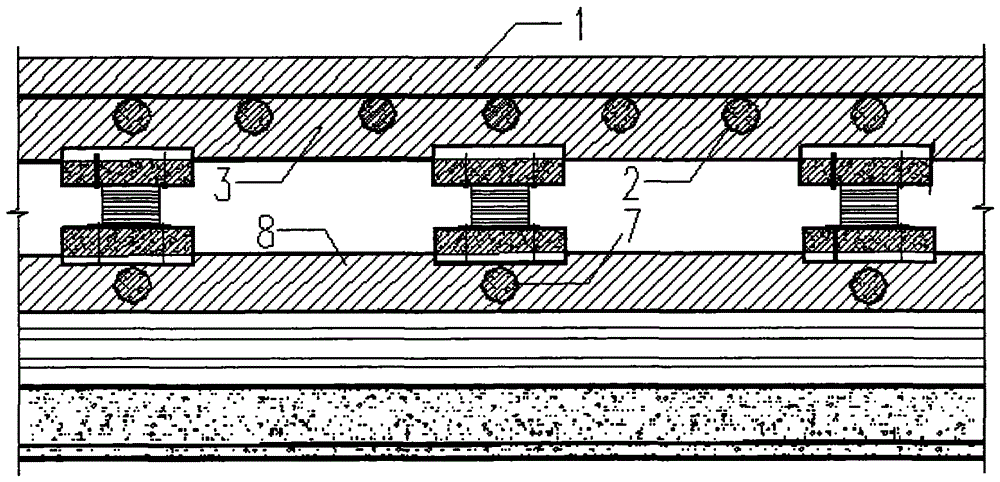

[0033] Such as Figure 1~3 Shown, the specific embodiment of the present invention is as follows:

[0034] A brick-concrete reinforced structure for seismic isolation bearings, including geosphere beam 1, prefabricated pin key beam, upper shoulder beam 3, lower shoulder beam 8, upper sealing plate 4, lower sealing plate 6, seismic isolation bearing 5, prefabricated pin The key beam is divided into an upper prefabricated pin key beam 2 and a lower prefabricated pin key beam 7, the load-bearing wall below the geosphere beam 1 is divided into upper and lower parts, and a shock-isolation support 5 is arranged between the upper and lower load-bearing walls ; On the upper load-bearing wall, there are prefabricated pin beam holes at intervals, and an upper prefabricated pin beam 2 is inserted in the hole; on the lower load-bearing wall, prefabricated pin beam holes are arranged at intervals, and a lower prefabricated pin beam 7 is inserted in the hole The upper and lower prefabricat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com