Whirlwind type oil-gas separator having self-sealing oil return structure

An oil-gas separator and self-sealing technology, which is applied in the directions of crankcase ventilation, machine/engine, engine components, etc., can solve the problems of high manufacturing or use cost, complex shape of cylinder head cover, low efficiency of oil-gas separation, etc., and achieve manufacturing Low cost, solve the problem of poor oil return, and improve the efficiency of oil and gas separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

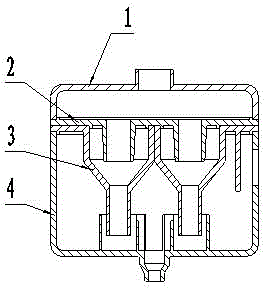

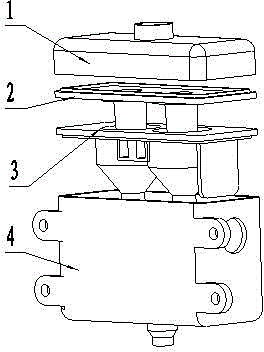

[0022] 1 and 2, the present invention includes an upper cover 1, a first kit 2, a second kit 3 and a bottom case 4, the first kit 2 is assembled with the second kit 3, and they are installed on the bottom case 4 and the upper case In the cavity formed by the cover 1, the bottom case 4 is fixed on the engine cylinder head cover through the mounting holes 4-6 on the outer wall thereof.

[0023] Referring to Figure 1, figure 2 , Image 6 , Figure 7 , the bottom casing 4 of the present invention is provided with a bottom casing blow-by gas inlet 4-1 on the side wall, and two self-sealing oil storage tanks 4-2 are symmetrically arranged at the bottom of the inner cavity of the bottom casing, and between the two self-sealing oil storage tanks There is an oil guide groove 4-3 and an oil return hole 4-4 between them, and the self-sealing oil storage tank 4-2 is connected to the oil guide groove 4-3 through the self-sealing oil storage tank opening 4-5 set on the top thereof. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com