Duel-voltage, duel-maintenance and duel-follow current driving circuit

A drive circuit and power drive circuit technology, applied in the direction of engine components, valve details, valve operation/release devices, etc., can solve problems such as difficult to meet requirements, slow speed, and unsatisfactory high-speed solenoid valve applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

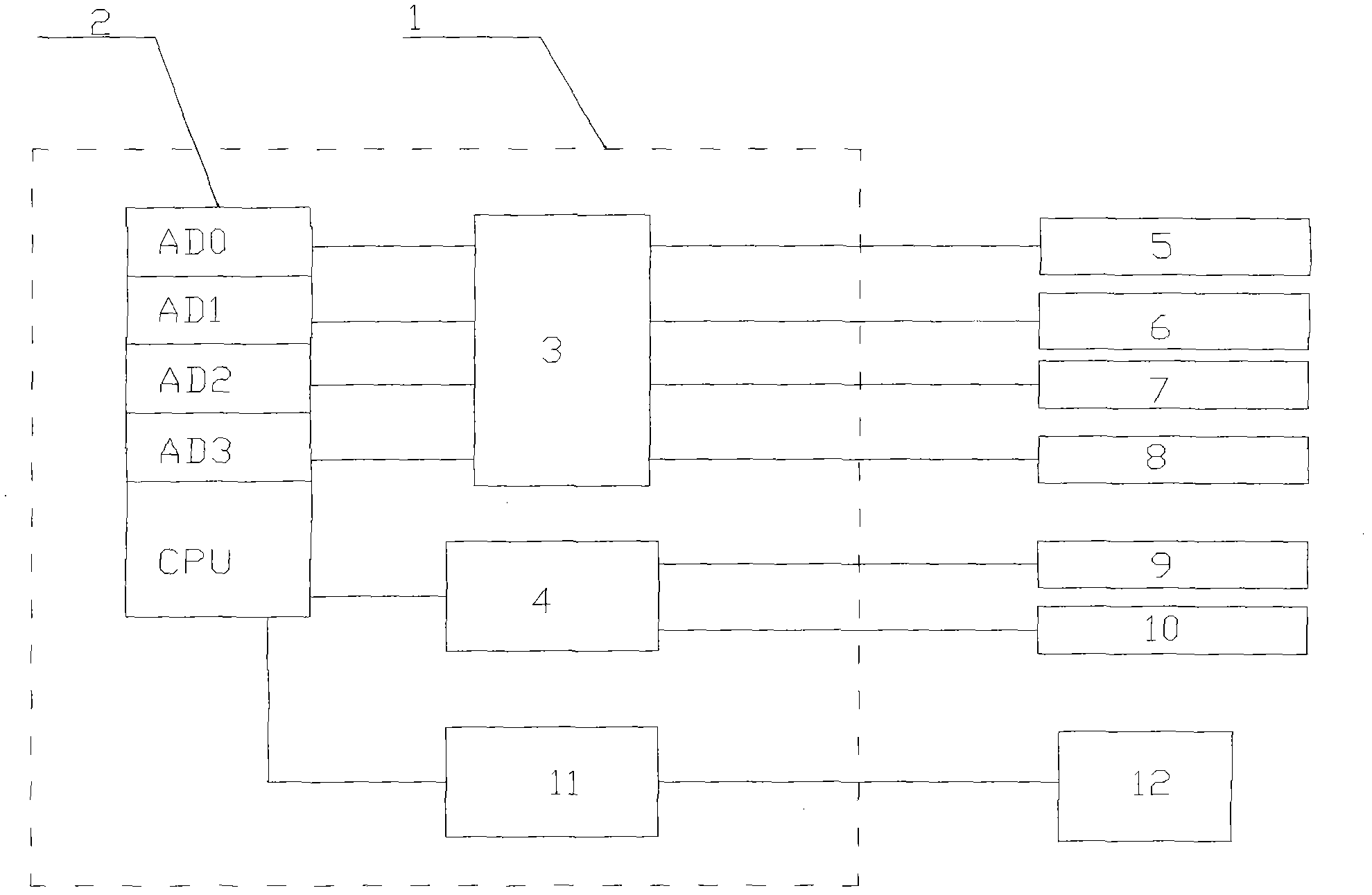

[0014] Embodiments of the invention: figure 1 It is a schematic diagram of a dual-voltage, dual-maintenance, and dual-freewheel drive circuit according to the present invention, which includes a driver 1 and a solenoid valve 12; it is characterized in that the signal input end of the driver 1 is composed of six adjustment knobs, which are respectively PWM duty cycle Adjustment knob 5, PWM frequency adjustment knob 6, delay time adjustment knob 7, excitation time adjustment knob 8, high maintenance current adjustment knob 9, high / low maintenance current adjustment knob 10; the signal output end of the driver 1 is connected to the solenoid valve 12.

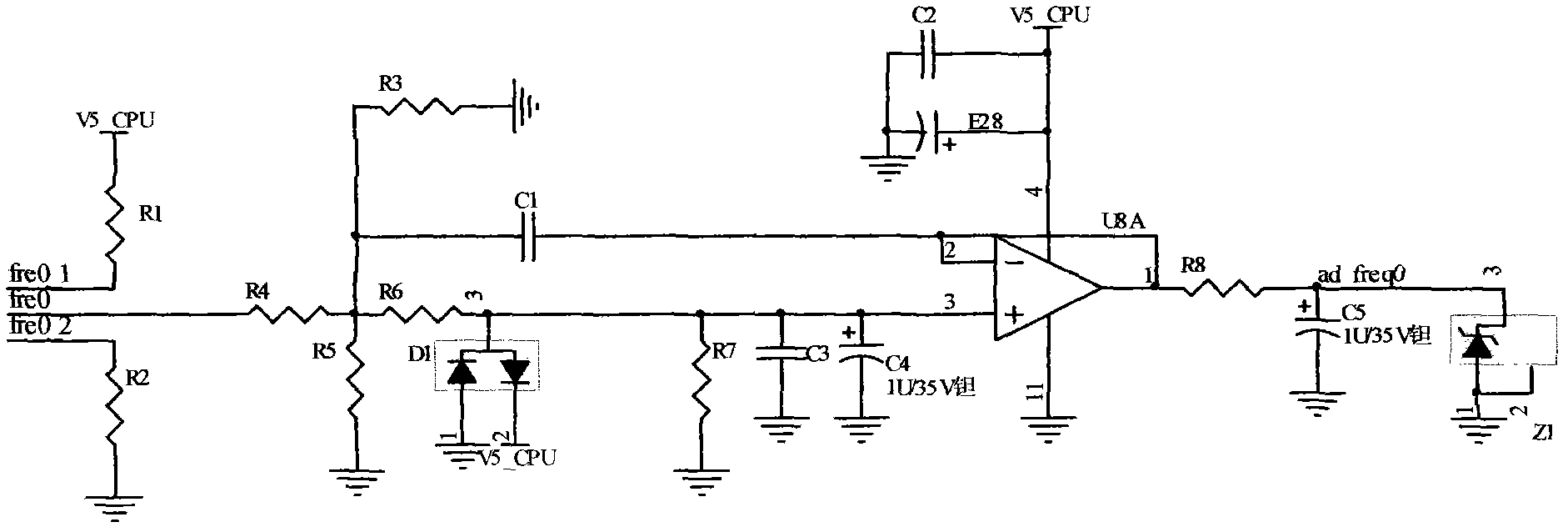

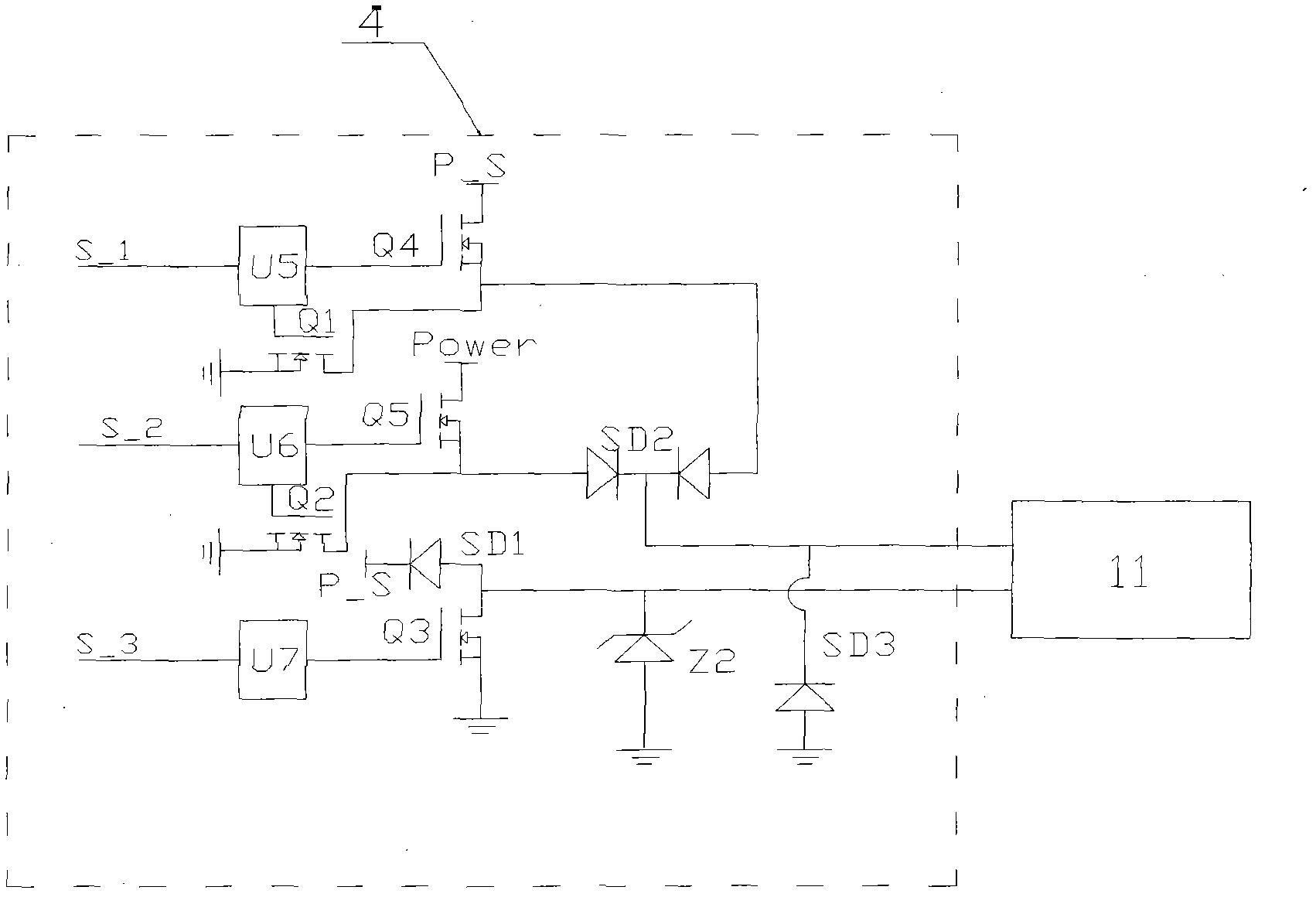

[0015] CPU2, input circuit 3, current comparison circuit 4 and power drive circuit 11 are provided in the driver 1; the signals of PWM duty ratio adjustment knob 5, PWM frequency adjustment knob 6, delay time adjustment knob 7 and excitation time knob 8 are input to Input circuit 3, input circuit 3 is connected to the digital-to-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com