Online detecting method of numerical control machining middle state of plane structural member

A technology for aircraft structural parts and intermediate states, applied in computer control, program control, comprehensive factory control, etc., can solve problems such as lack of detection methods and intermediate state models, and achieve the effects of reducing processing costs, preventing influences, and ensuring processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

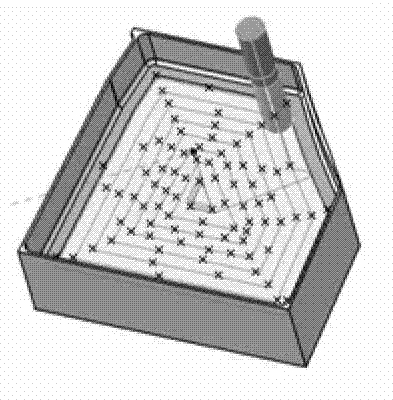

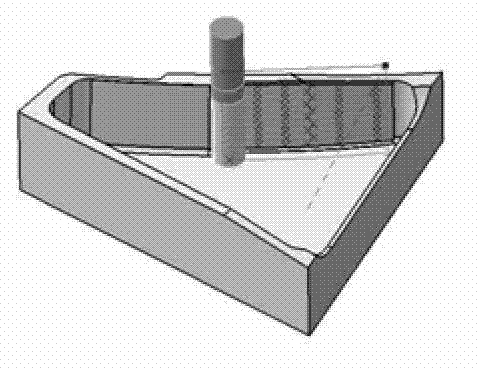

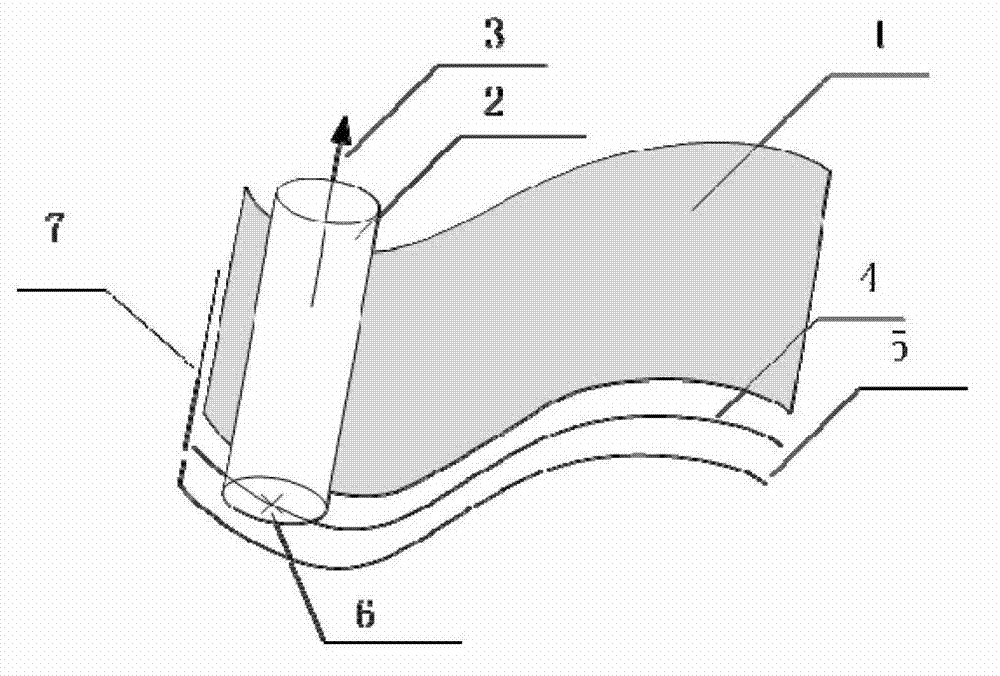

[0042] Such as figure 1 , figure 2 shown.

[0043] A method for detecting an intermediate state of numerical control machining of aircraft structural parts, the method comprising the following steps:

[0044] Step 1. Select the surface required for intermediate processing state detection based on the final state of the CAD model of the part;

[0045] Step 2. Determine whether the selected surface is a three-axis processing surface or a five-axis processing surface. If it is a three-axis processing surface, offset the surface by a machining allowance value along the outer normal direction of the surface to form a theory of an intermediate processing state Surface; if it is a five-axis machining surface, use the surface formed by the sweeping surface formed by the tool to move along the tool track when machining the intermediate state of the surface a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com