Drawing die for rectangular flat steel tube

A technology for drawing dies and steel pipes, which is applied in the direction of wire drawing dies, etc., can solve the problems of serious sag, high correction work intensity, and low efficiency of flat steel pipes, and achieve the effects of reducing production costs, ensuring stability, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

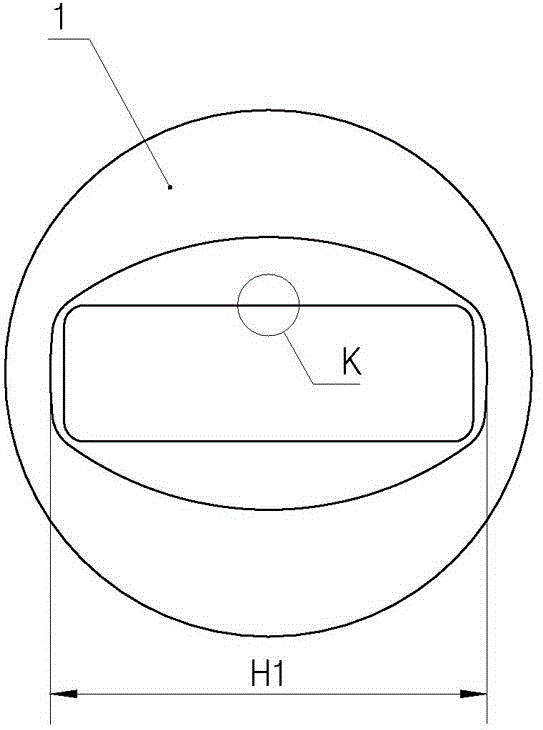

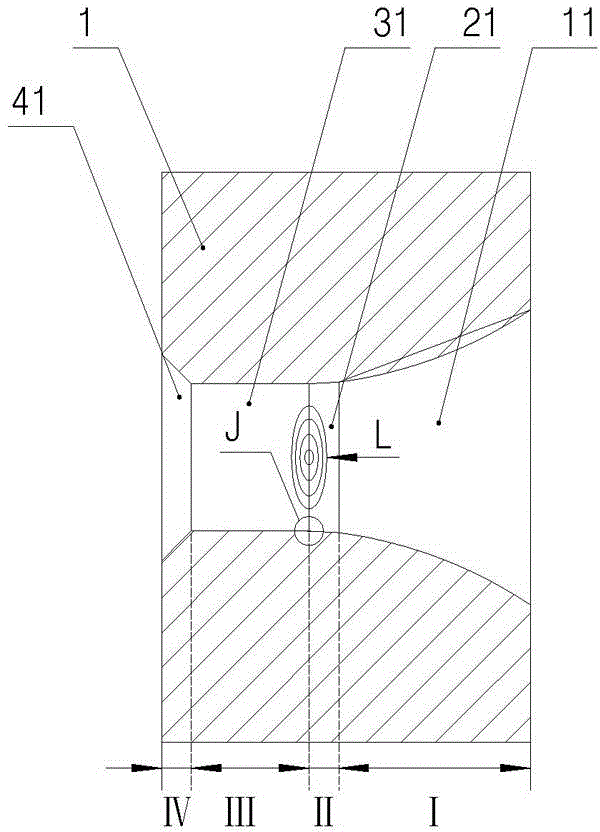

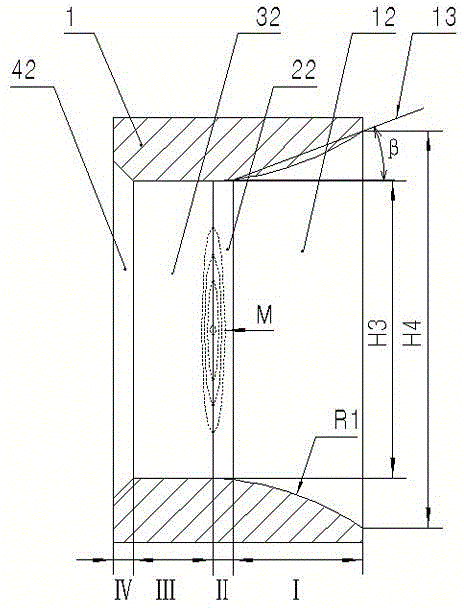

[0028] Such as figure 1 , figure 2 and image 3 Shown, the drawing die of the rectangular flat steel pipe of the present invention comprises: mold body 1, offers on the mold body 1 and comprises: successively connected inlet section I, transition section II and sizing section III and outlet section IV Drawing die hole, outlet section IV, sizing section III, transition section II and entry section I respectively account for 4.5%, 25%, 9% and 61.5% of the thickness of the die body 1; sizing section III includes: respectively Figure 6 A pair of straight short faces 31, a pair of arc-shaped long faces 32 and four connecting flat faces corresponding to the short side and the long side of the cross-sectional profile of the shown rectangular flat steel pipe 8 and the corner arcs connecting the short and long sides The corner arc surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com