An Assembled Rotary Blanking Die

An assembled and blanking technology, which is applied in the field of metal stamping, can solve the problems of limited frequency of reciprocating motion, and achieve the effect of smooth acceleration change, high rotation speed, and small rotation speed change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

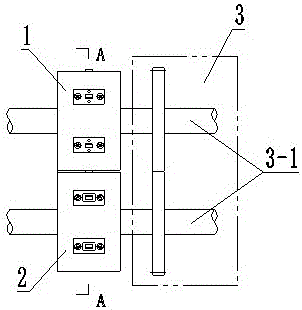

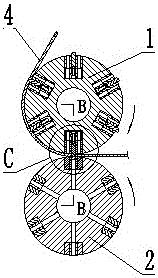

[0020] see figure 1 , figure 2 , the present invention includes a punch assembly 1, a die assembly 2 and a gear transmission mechanism 3, the gear transmission mechanism 3 is a pair of external gears with the same number of teeth and the same modulus, the punch assembly 1 and the die assembly Parts 2 are respectively fixedly assembled with the central shafts 3-1 of the two external gears, and the structures and installation positions of the punch assembly 1 and the die assembly 2 match each other.

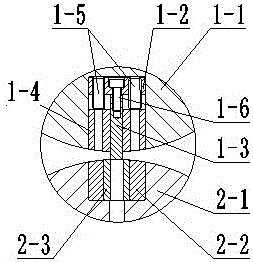

[0021] see image 3 , Figure 4 , the punch assembly 1 of the present invention includes a punch base 1-1, a punch insert 1-4, a punch adjustment block 1-2 and a punch 1-3, and the punch base 1-1 is a cylinder structure, a group of punch insert positioning holes are evenly arranged on the cylindrical surface, and the punch inserts 1-4 are installed in the punch insert positioning holes, and the punch inserts 1-4 are provided with punch positioning holes. hole, the punch 1-3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com