Ultrahigh-strength steel plate local quenching and hardening forming die

A technology of local quenching and forming molds, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of limited safety improvement, poor strength, and low elongation of the body structure, and achieve improved collision safety performance and huge economic benefits. Benefits, the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

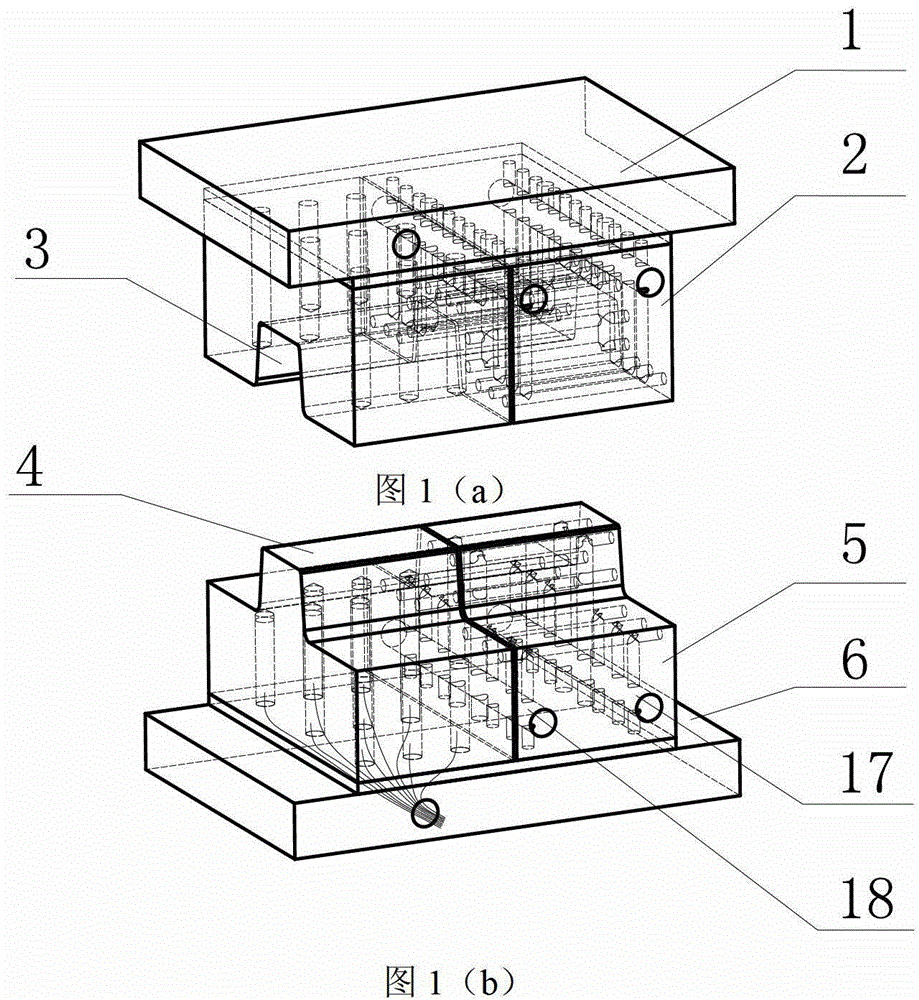

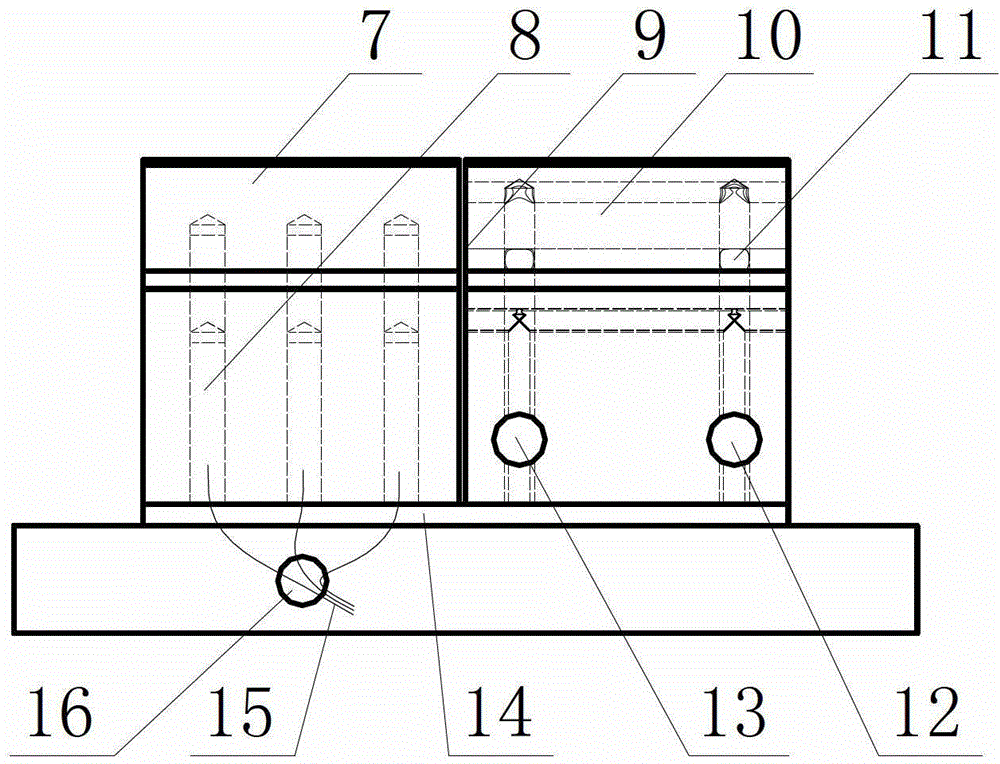

[0018] See Figure 1 with figure 2 , taking automobile U-shaped reinforced beam parts as an example, the mold includes a mold die 2 and a punch 5, on which are respectively provided profiles 3 and 4 corresponding to the structural shapes of automobile U-shaped reinforced beam parts, and the die 2 and the punch 5 are fixed on the upper mold base 1 and the lower mold base 6 respectively.

[0019] The concave mold 2 and the convex mold 5 are designed as an inlaid structure according to the requirements of the strength and toughness of different regions of the parts.

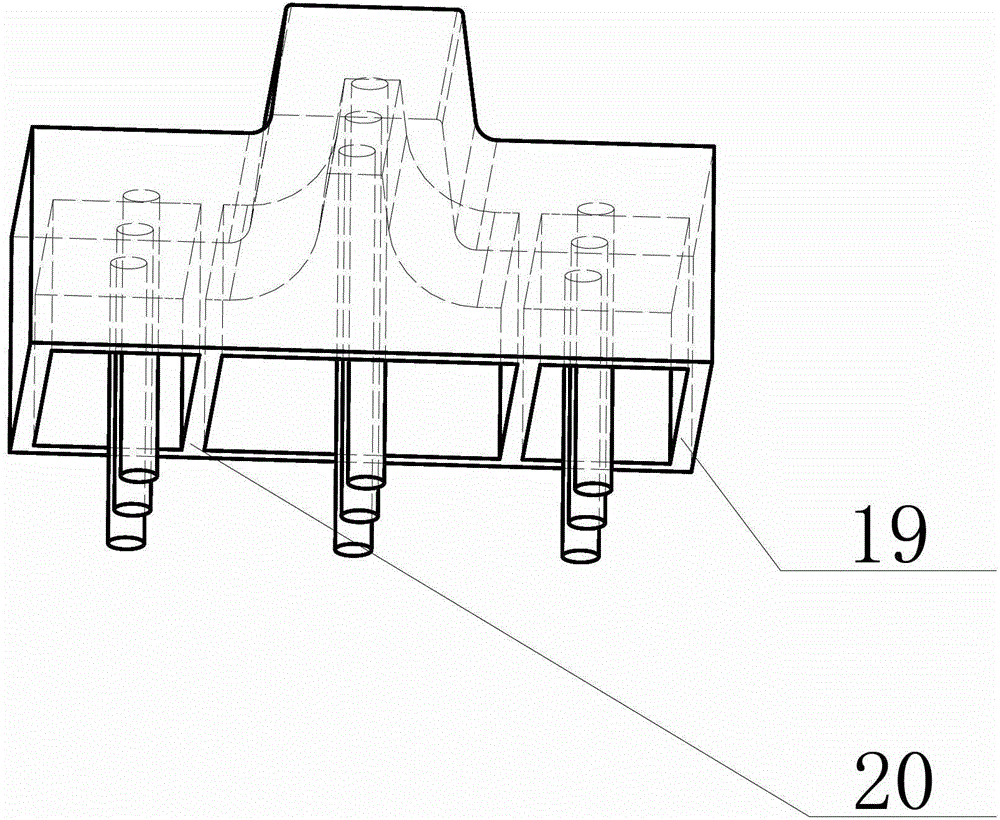

[0020] Taking the punch 5 as an example, the punch 5 is composed of a heating insert 7 and a cooling insert 10. Inside the heating insert 7, 6-10 single-head stainless steel electric heating tubes 8 are arranged, and the diameter of the electric heating tube 8 is 12- 20mm, the distance between the heating tube walls is not less than 10mm, the distance between the top of the heating tube 8 and the mold surface 4 is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com