Rotary joint welding method for main shafts of different materials

A welding end and welding connection technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems that the friction welding strength is difficult to guarantee, and achieve the effect of improving welding quality, increasing strength, and increasing friction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

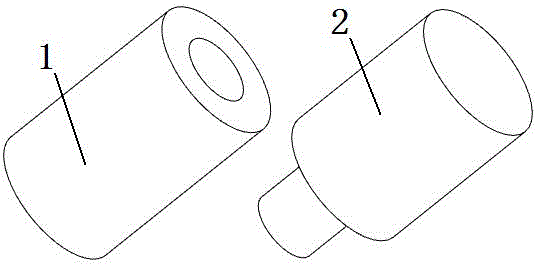

[0020] Such as figure 1 As shown, the screw welding process for large shafts of different materials of the present invention requires punching at the center of the welding end face of the shaft to be welded A1, and a reserved boss at the center of the welding end face of the shaft to be welded B4 before welding. Treatment, the length of the boss on the shaft B 4 is 2-5 mm larger than the depth of the pre-drilled hole on the shaft A 1, which provides a suitable welding gap for the formation of the ordinary welding seam 3.

[0021] The method for screwing and welding different materials with large shafts according to the present invention includes the following steps:

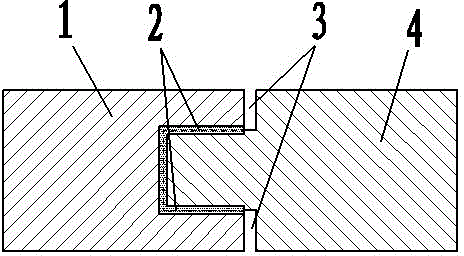

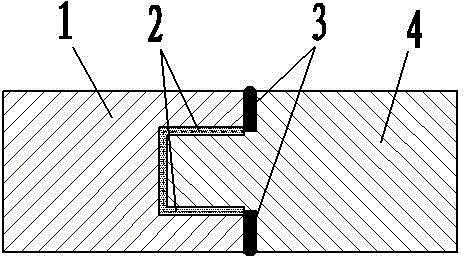

[0022] 1. Match the pre-drilled and reserved boss axis A 1 and axis B 4 with the boss and perform friction pre-welding to obtain figure 2 The friction pre-welded friction weld 2 shown;

[0023] 2. What you get after friction pre-welding figure 2 Normal welding is performed in the gap between the welding end faces of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com