Angle ejector rod with stress step

A technology of inclined ejector and steps, which is applied to the field of inclined ejectors with stressed steps, can solve the problems of decreased injection molding production efficiency, high maintenance cost, low production efficiency, etc., so as to improve the qualified rate of products, reduce maintenance costs, The effect of extended operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

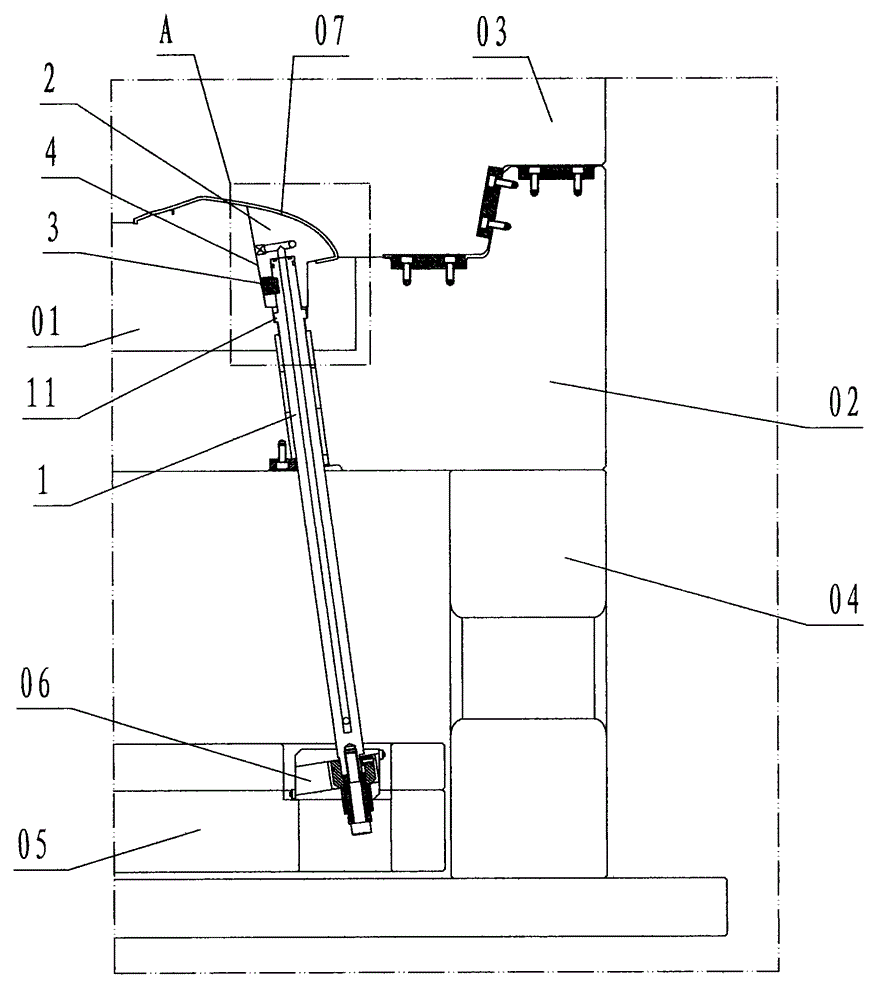

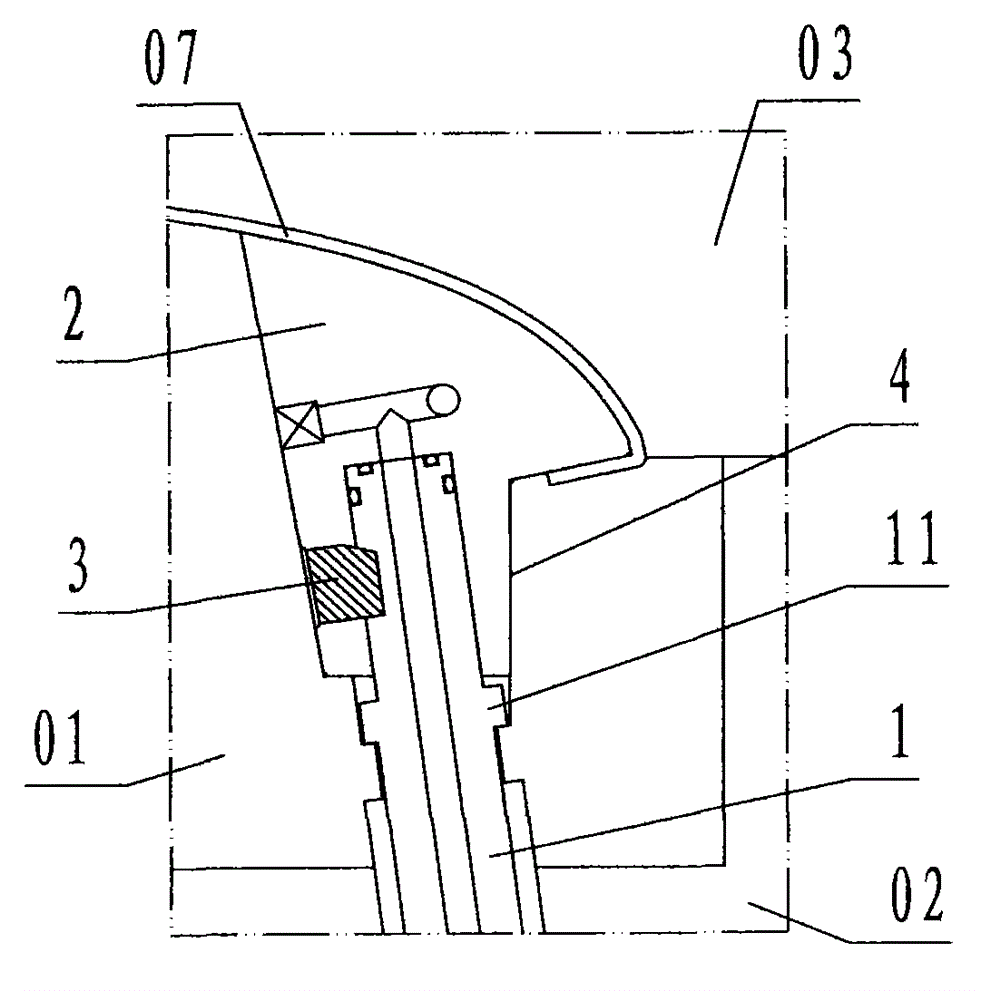

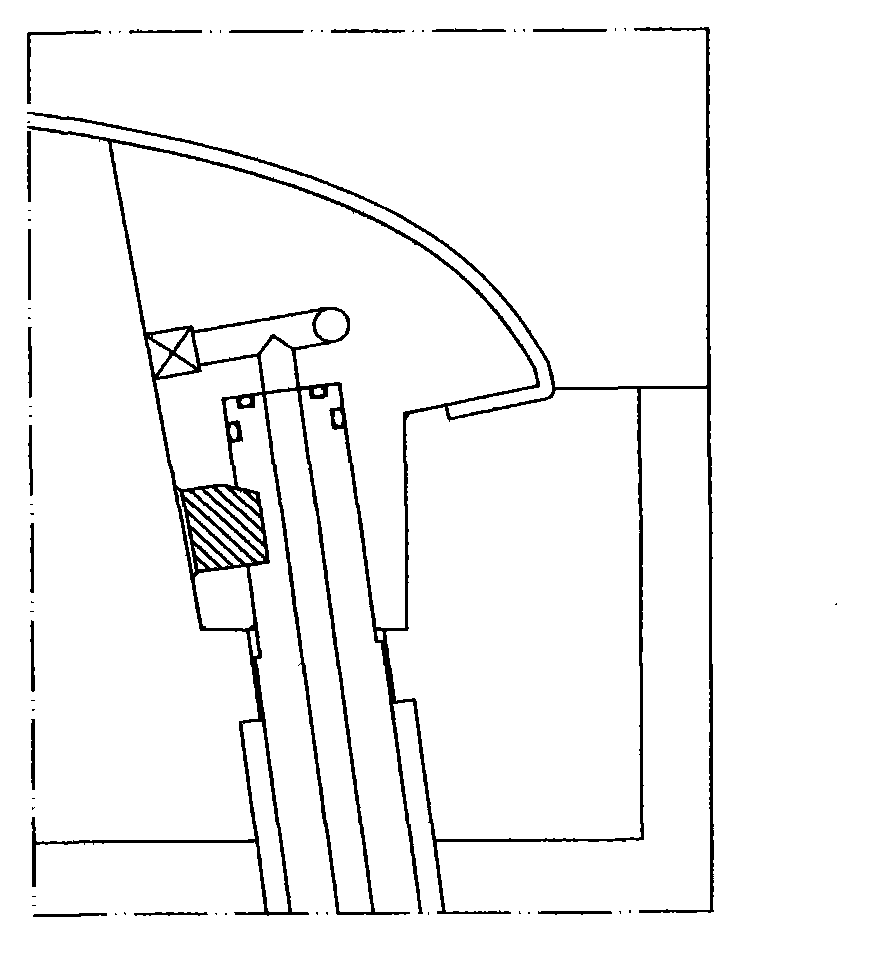

[0016] refer to figure 1 , figure 2 , a kind of inclined ejector rod provided with a stressed step of the present invention includes an inclined ejector rod 1 and a stressed step 11, and the inclined ejector rod 1 is a cylindrical step-shaped tubular steel member with a hollow cooling water channel in the center , the upper cylindrical surface of the inclined ejector rod 1 is provided with a circle of cylindrical flange steps called force steps 11;

[0017] Application connection, the upper end of the jacking rod 1 is inserted into the bottom hole of the jacking block 2, and is fixedly connected with each other by the key pin mortise of the jacking rod 1 and the jacking block 2 with the key pin 3. At this time, the force The step 11 is positioned below the bottom surface of the slanting top block 2; a step groove carrying the stressed step 11 is set at the bottom of the groove 4 of the moving model core 01 for slidingly arranging the slanting top block 2, and The groove bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com