Multi-station rotary welding equipment

A rotary welding and multi-station technology, applied in the field of welding equipment, can solve problems such as troublesome operation, harsh working environment for operators, difficulty in guaranteeing welding quality, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

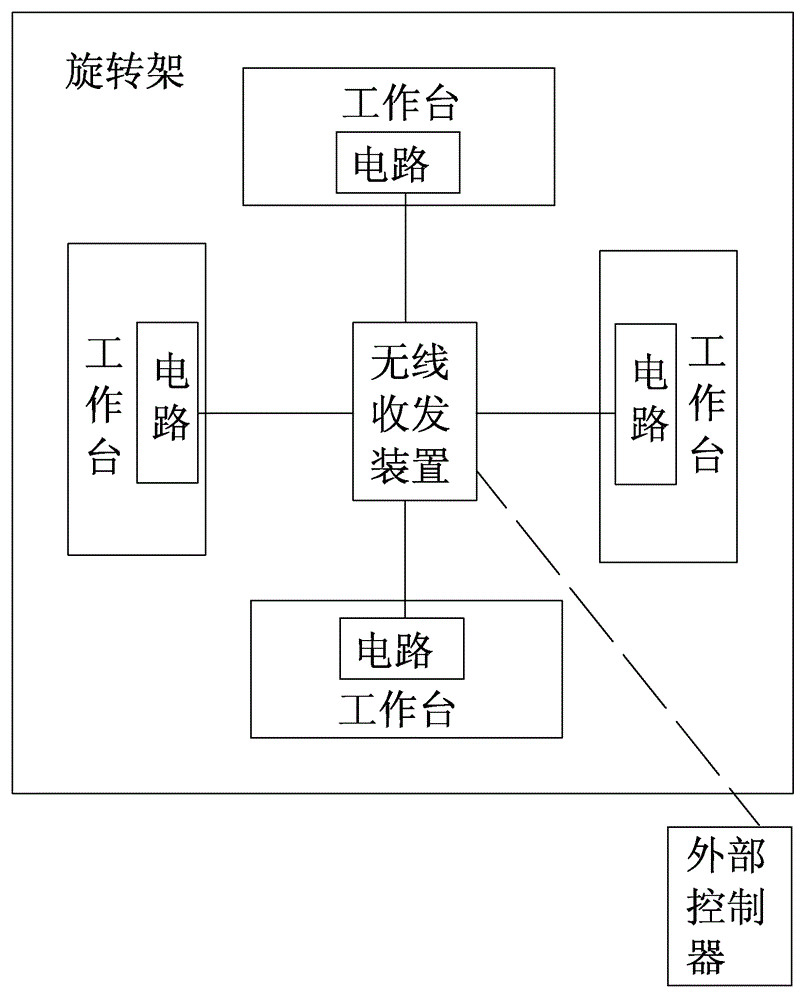

[0008] Such as figure 1 The multi-station rotary welding equipment includes a welding head, a worktable and a rotating frame. There are multiple worktables and they are all installed on the rotating frame. A wireless transceiver device for wireless communication with an external controller is installed on the rotating center of the rotating frame. The wireless transceiver device is wired to connect the circuits of each workbench. The external controller controls the action of each workbench through the circuit of each workbench, and the circuit of each workbench feeds back the working status to the external controller.

[0009] As the carousel rotates, each table moves in circles to reach each station. The wireless transceiver device is always located at the rotation center of the rotating frame, which ensures the quality of wireless communication with the external controller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com