Heat-insulating packing case and method for manufacturing same

A packaging box and heat insulation layer technology, applied in the field of machinery and electronics, can solve the problems of weakened structural strength, poor pretreatment efficiency, and inability to support multiple pretreatment methods, so as to achieve the effect of improving efficiency and enhancing heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

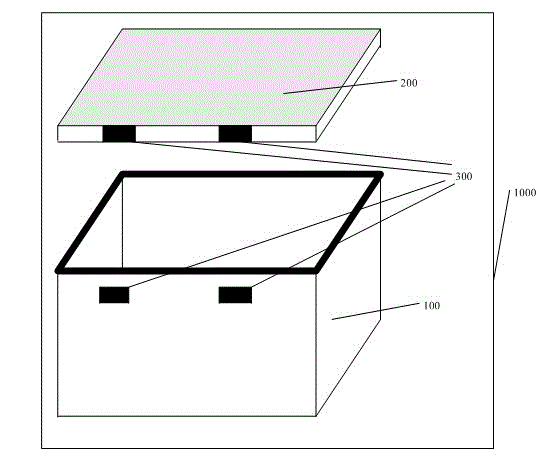

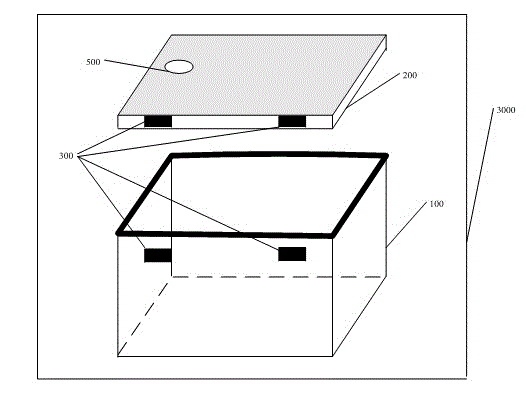

[0039] Such as figure 1 As shown, the heat-insulated packaging box of the present invention includes: a box body 100, a box cover 200 integrating a fixing groove 210 and a sealing ring 220, and a buckle lock 300. Both the box body and the box cover are made of three-layer materials, which are respectively shell Layer 110, heat insulation layer 150, inner liner layer 160 and sealing strip 180, a fixing groove 210 is installed at the position where the inner liner layer of the box cover is combined with the box body, and a sealing ring 220 is installed in the fixing groove 210, and a sealing ring 220 is installed on the box cover 200 When the box body 100 is in place, the locking effect of the buckle lock is used to stabilize and seal the box body, and when an item requiring heat insulation is put in, it is used to delay the heat exchange between the item and the environment.

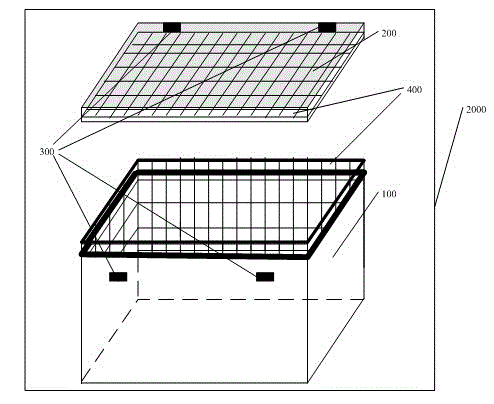

[0040] Such as figure 2 As shown, the present invention also provides a heat-insulated packaging bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com