Method for preparing environment-friendly coated snow-melting agent

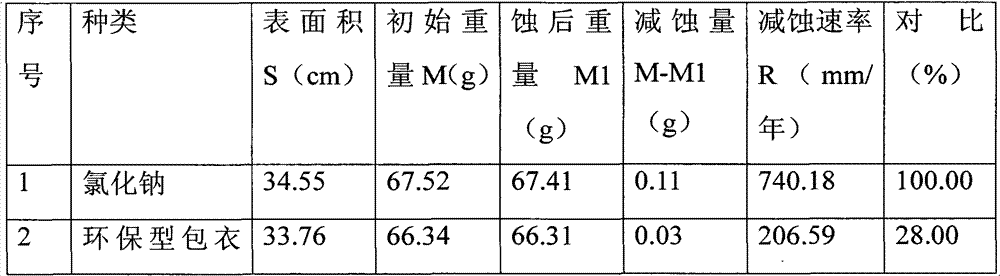

A production method and technology of snow-melting agent, applied in the field of production of environment-friendly coated snow-melting agent, can solve problems such as corrosion, achieve the effect of protecting roads and bridges, and having a good snow-melting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1, a kind of preparation method of environment-friendly coated deicing agent, is characterized in that: comprises the following steps successively:

[0013] (1) Mixing: get the industrial salt with a water content of 4%-6%, mix the corrosion inhibitor sodium citrate which is 2%-3% of industrial salt by weight into the industrial salt, and mix the two evenly ;

[0014] (2) Pulverization: Send the mixed industrial salt and sodium citrate into the pulverizer by the belt conveyor, pulverize to a particle size of 5mm, and the sodium citrate evenly adheres to the pulverized industrial surface of salt particles;

[0015] (3) Drying: The industrial salt particles adhered to sodium citrate are fed into the vulcanized bed by a belt conveyor, and jump, roll and move forward under the blowing of high-temperature and high-pressure air with a temperature above 280°C. After drying, they form coated granules;

[0016] (4) Cooling: cooling the coated granules to room tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com