Multi-guide-bar warp knitting machine

A technology of warp knitting machine and bar, which is applied in warp knitting, textiles, papermaking, knitting, etc. It can solve the problems of easy loosening and affecting the normal operation of the machine, and achieve the effect of rich variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

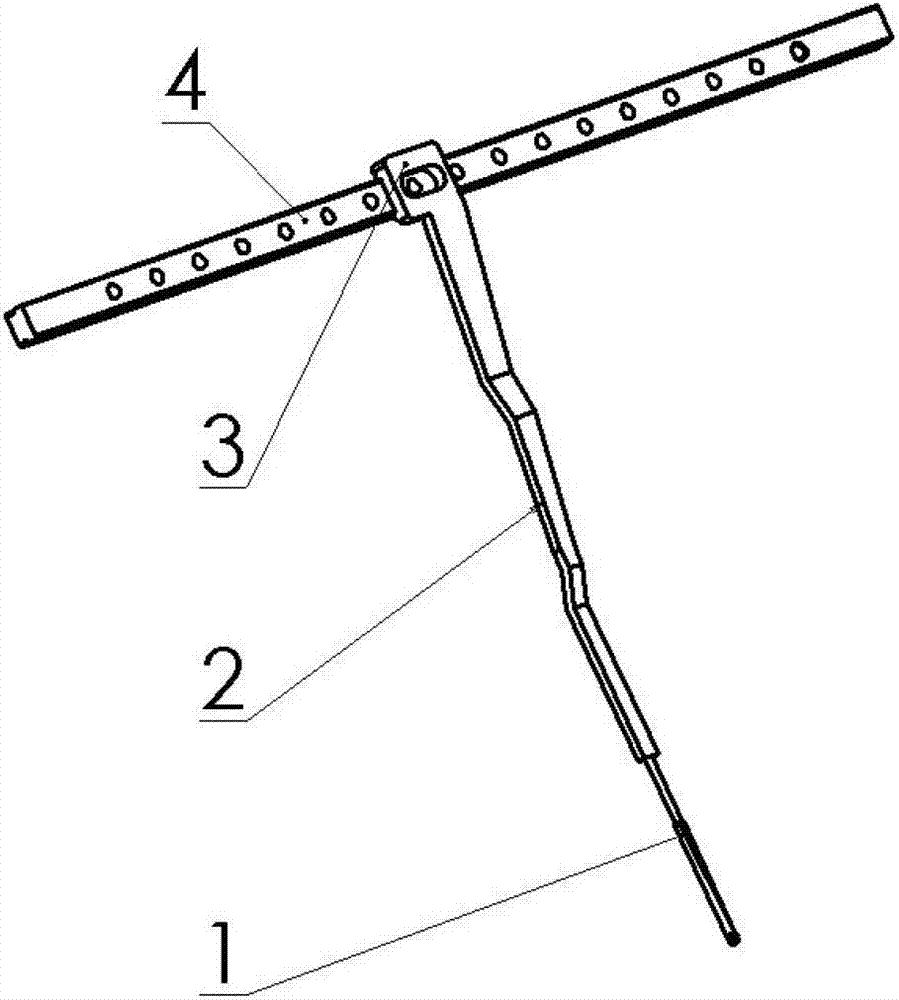

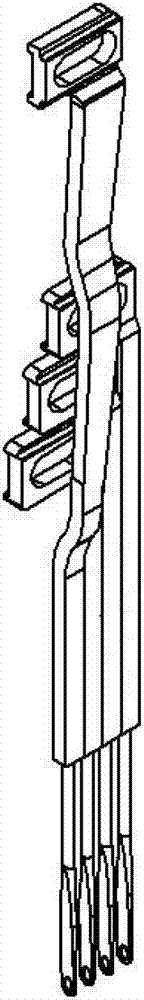

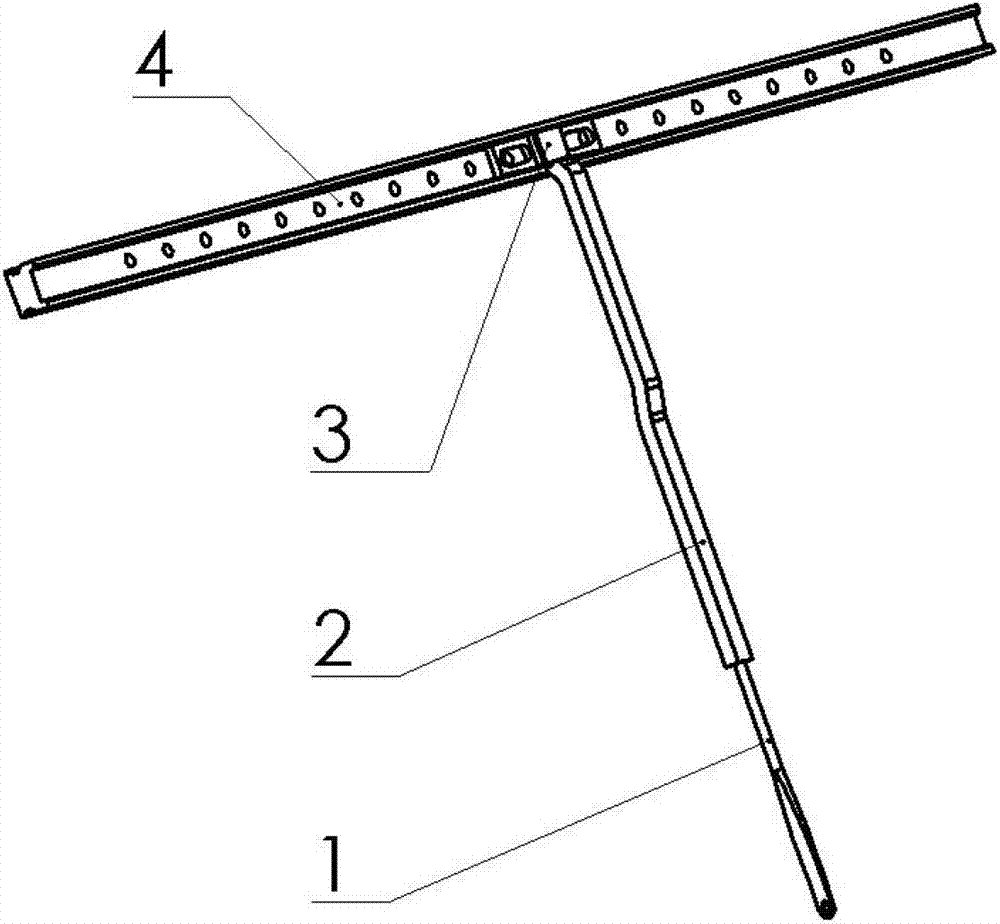

[0014] Such as image 3 and 4 Shown, a kind of multi-bar warp knitting machine comprises bar, bar includes bar base and bar slide bar 4 that moves on bar base, flower comb needle is installed on bar slide bar 4, flower bar The comb needle includes a needle head 1 and a needle bar 2. The needle head 1 is fixed on the needle bar 2. Both sides of the end of the needle bar 2 are provided with a fixed end 3. The fixed end 3 and the needle bar 2 form a T-shaped integral structure. The fixed end 3 There are mounting holes on it;

[0015] The mounting surface of the comb slide bar 4 is provided with a plurality of screw holes for installing with the flower comb needle screws, and a groove is opened on the mounting surface, and the screw holes are located in the groove;

[0016] The fixed end 3 of the flower comb needle is embedded in the groove, and the screw fixes the flower comb needle and the bar slide bar 4 through the mounting hole and the screw hole.

[0017] The needle head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com