High-rise and ultrahigh-rise floor system

A super high-rise and floor technology, applied in the direction of floors, building components, buildings, etc., can solve the problems of inconvenient construction and large steel consumption, and achieve the effect of facilitating construction and shortening the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

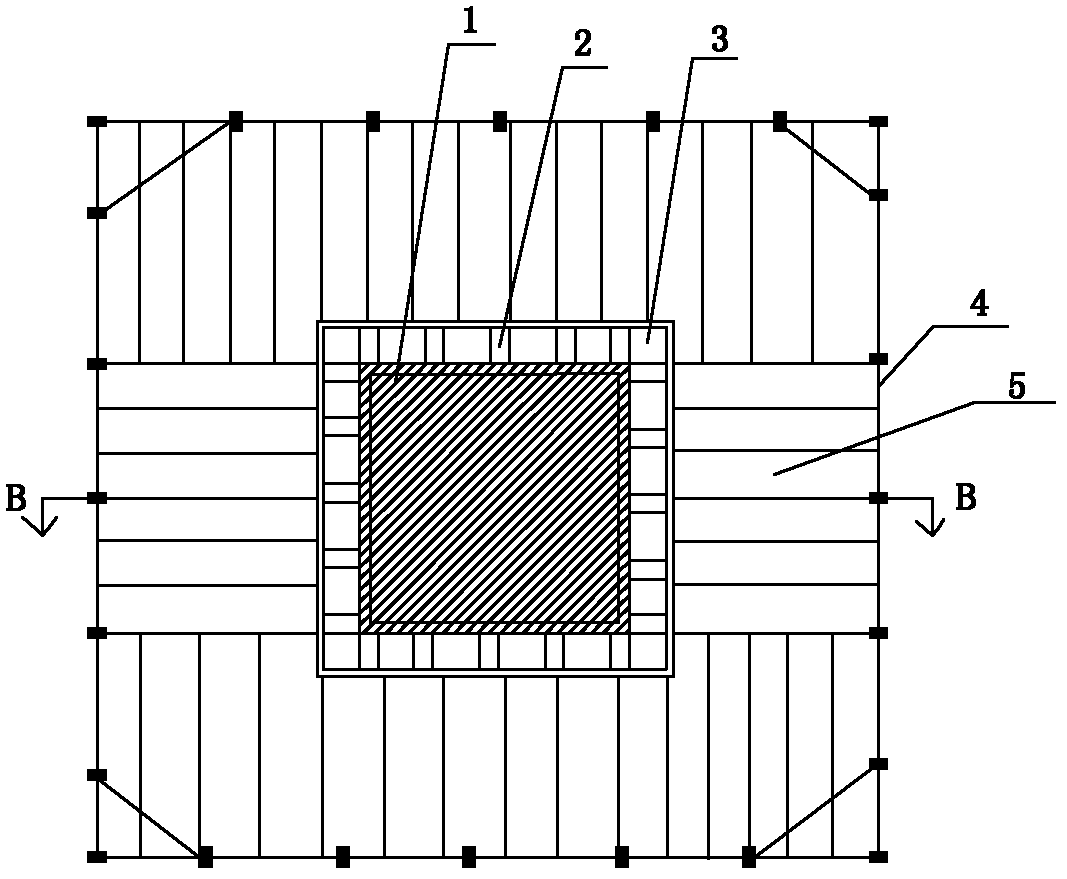

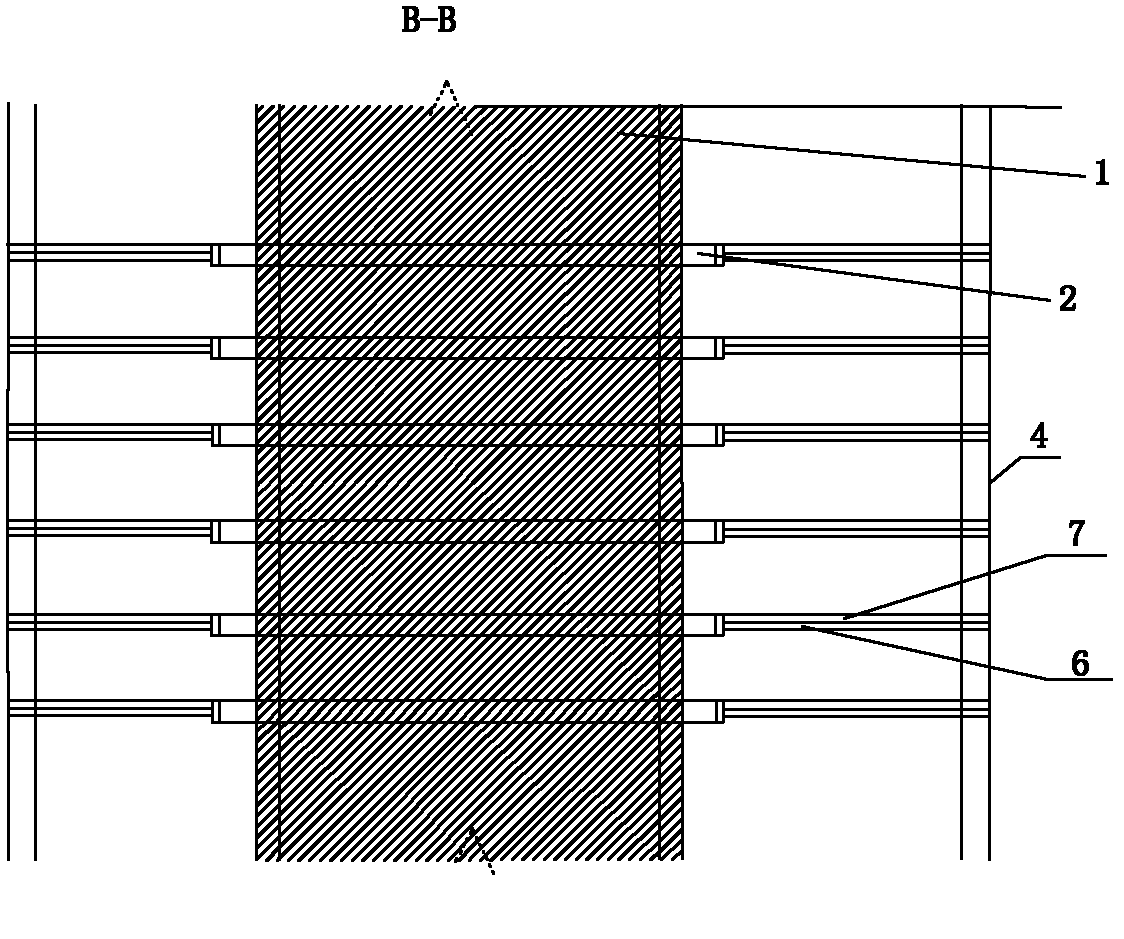

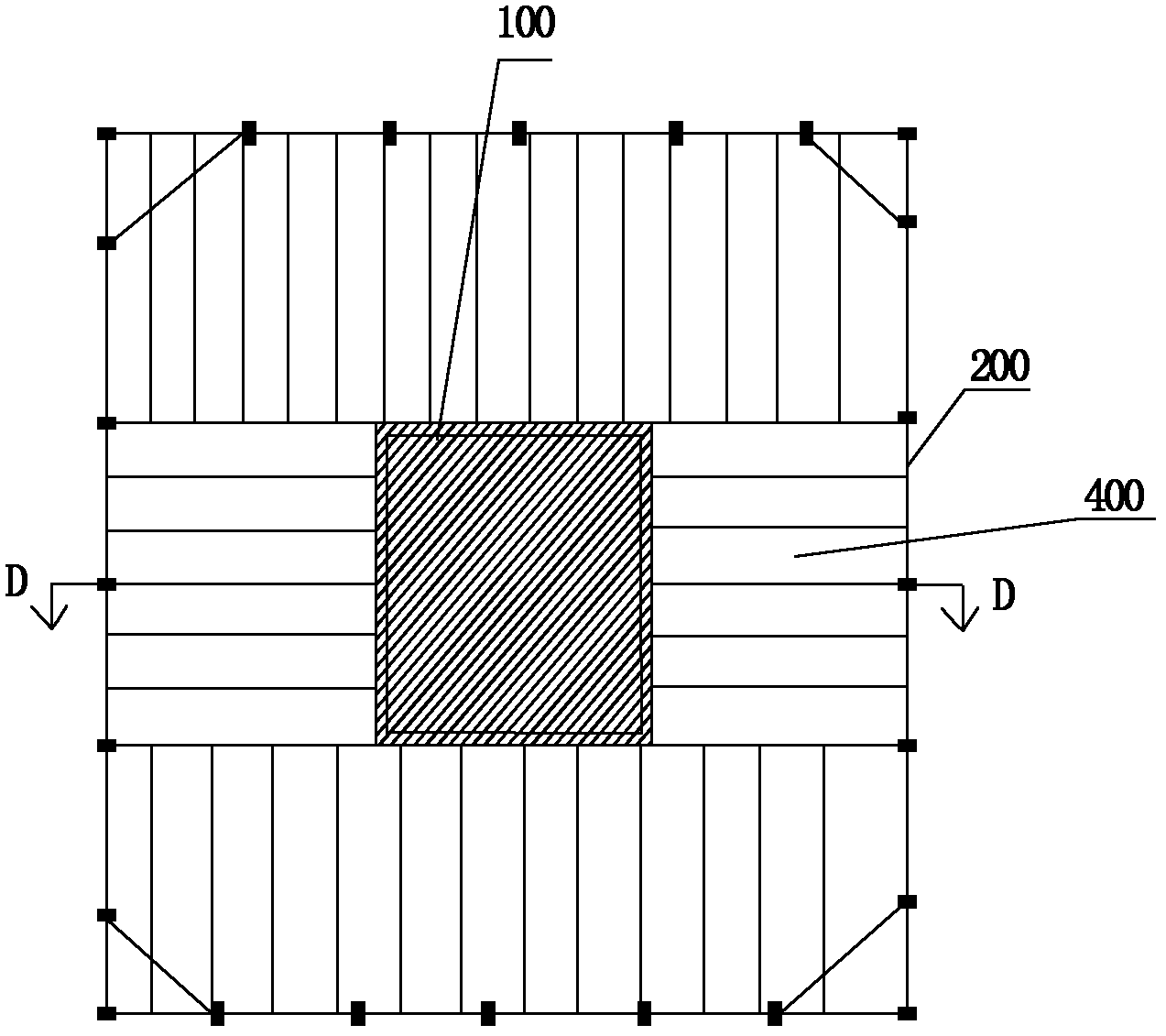

[0033] Combine figure 1 , figure 2 As shown, in the first embodiment of the high-rise and super high-rise building cover system of the present invention, it includes a core tube 1, which is built on a foundation and penetrates all floors, a core tube peripheral steel structure 4 around the core tube 1, and a combination Floor 5, the core tube 1 is provided with a plurality of cantilever beams 2 at intervals on the floor, the cantilever beams 2 are in the same plane, and all the cantilever beams 2 on the same floor form a whole cantilever beam by pouring reinforced concrete Cantilevered floor 3; The combined floor 5 is arranged between the cantilevered floor 3 and the outer steel structure 4 of the core tube.

[0034] in figure 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com