Bearing pedestal sealing device for roller of rolling mill

A technology of sealing device and bearing seat, which is applied in the direction of metal rolling mill stands, bearing elements, shafts and bearings, etc., which can solve problems such as abnormal roll operation, difficulties in production operation and maintenance personnel, and roll wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

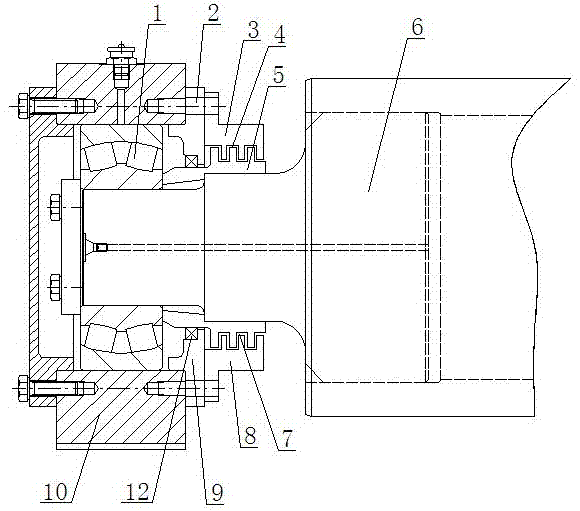

[0013] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

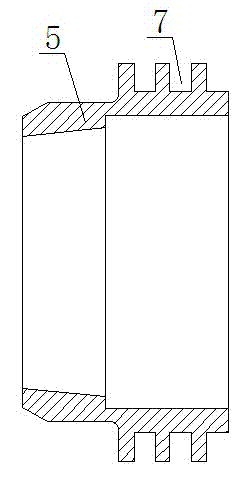

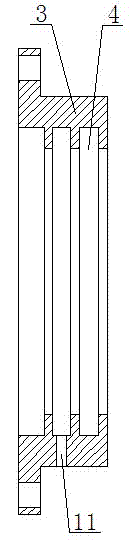

[0014] A bearing seat sealing device for rolling mill rolls, as shown in the figure, a bearing 1 is installed at the end of the roll 6, and the bearing 1 is installed in the bearing seat 10, and the journal of the roll 6 is also equipped with a labyrinth seal inner ring 5. The end of the sealed inner ring 5 is fixedly connected to the inner ring of the bearing 1, and the outer peripheral surface of the sealed inner ring 5 is provided with a plurality of rings of rectangular sealing chambers I7. The outside of the sealed inner ring 5 is fitted with a sealed outer cover. The sealed outer cover is a split type. It includes a sealed upper cover 3 and a sealed lower cover 8. When disassembling or replacing the sealed outer cover, there is no need to disassemble the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com