Conical helical spring buffer

A truncated cone coil spring and buffer technology, applied in the direction of springs/shock absorbers, low internal friction springs, shock absorbers, etc. Risks, increase the influence of the inertial force of the cargo, etc., to achieve the effect of eliminating resonance, slowing down and resonance, and prolonging the action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

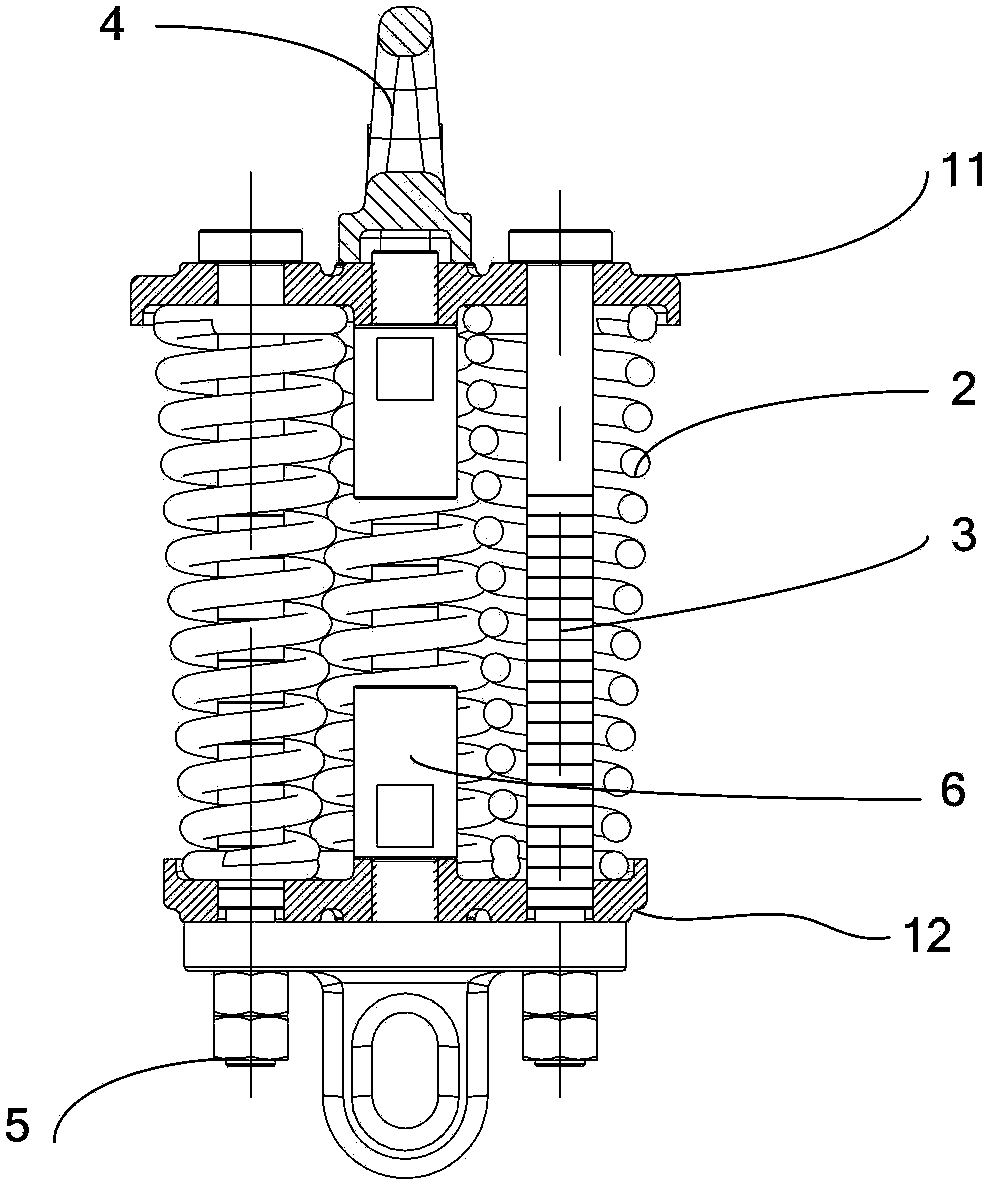

[0028] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

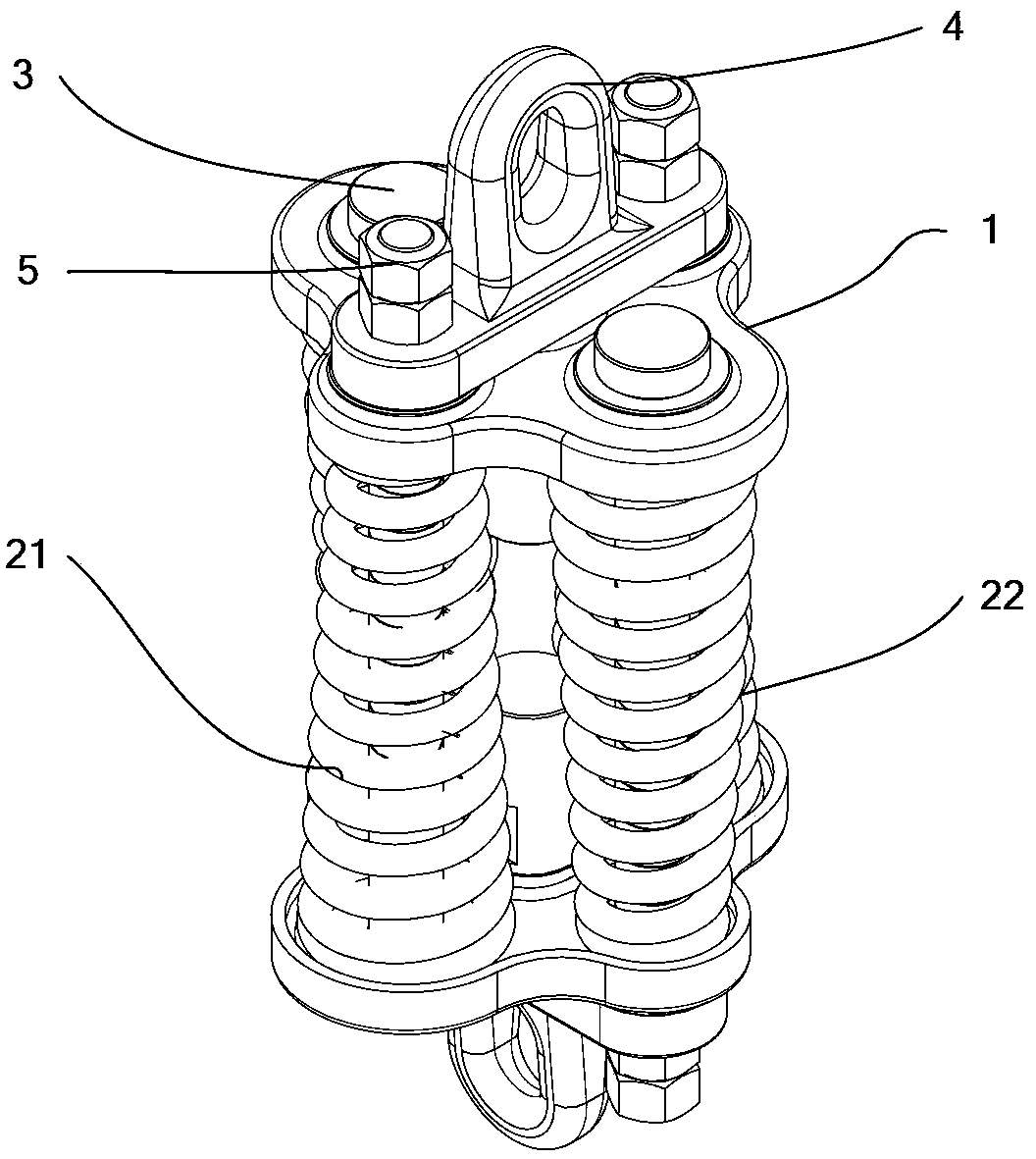

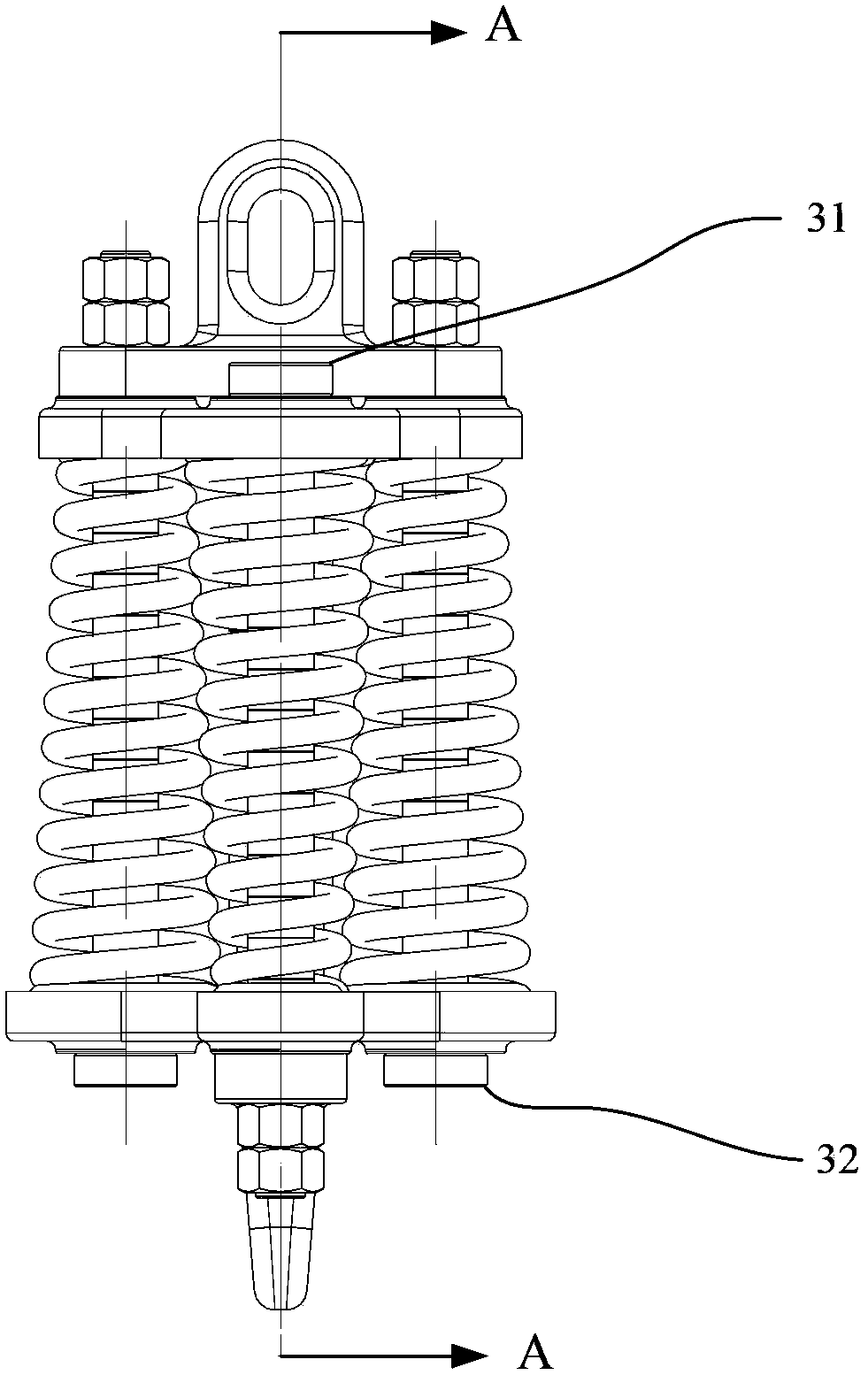

[0029] The utility model relates to a truncated cone spring type buffer, which plays a buffering role in the bundling and reinforcement of steel materials, wheeled engineering machinery, bulky goods and large packing boxes during road transport, rail transport, and sea transport. The buffer is provided with a connecting platen 1 and a truncated cone coil spring 2. The connecting platen 1 includes a first connecting platen 11 and a second connecting platen 12. The truncated cone coiled spring 2 is arranged on the first connecting platen 11 and the second connecting platen. Connect between the pressing plates 12. The truncated cone coil spring 2 refers to a coil spring in a conical shape, and the coils at both ends of the coil spring 2 are arranged from large to small. The first connecting pressing plate 11 and the second connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com