Production process of bright enhancement film of LCD (liquid crystal display) backlight module

A production process and backlight module technology, which is applied in the LCD field, can solve the problems of low qualified product rate, high energy consumption, and large investment in equipment, and achieve the goal of improving brightness coefficient, increasing brightness and viewing angle, and increasing light transmittance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

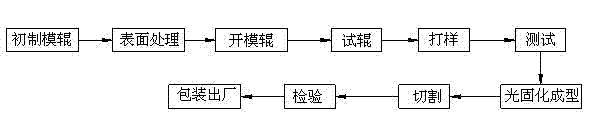

[0012] refer to figure 1 , the specific implementation method adopts the following technical scheme: its production process is: initial mold roll —> surface treatment —> mold opening roll —> test roll —> proofing —> test —> photocuring Forming—>cutting—>inspection—>packing and leaving the factory.

[0013] It is worth noting that the mold rolls in the process described above are processed by a single-point diamond ultra-precision machine tool.

[0014] It is worth noting that the mold rolls in the process described above are precisely machined with diamond tools.

[0015] The rotation accuracy of the CNC machine tool spindle used in this specific embodiment can reach 0.01 μm, and it is processed at a constant temperature of 20±0.1°C to 20±1°C, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com