Flanged inverted glass metal vacuum heat collector

A vacuum heat collector tube and glass metal technology, which is applied in heating devices, solar thermal devices, solar thermal power generation, etc., can solve the problems such as the inability to solve the radial expansion difference between glass and metal, the inability to meet the requirements of high temperature vacuum exhaust, and the inability to meet the requirements. , to achieve the effect of compact structure, increased effective lighting area, and increased interface force capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

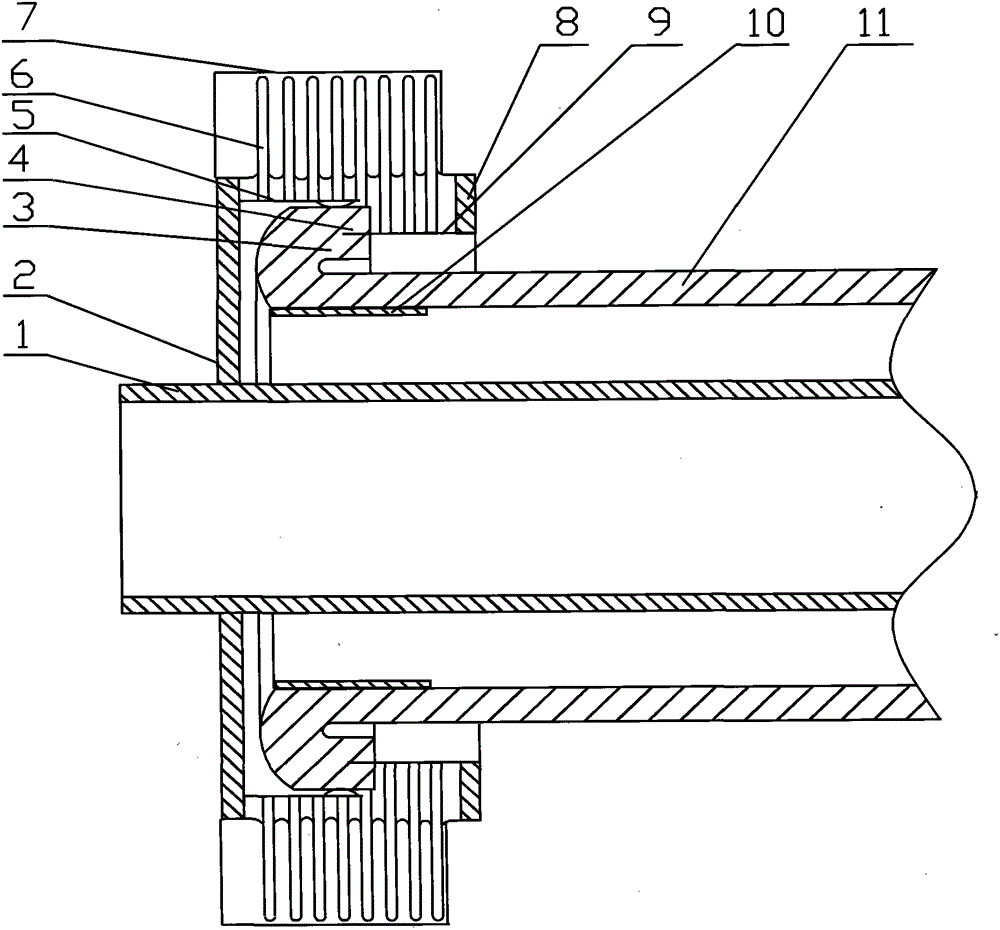

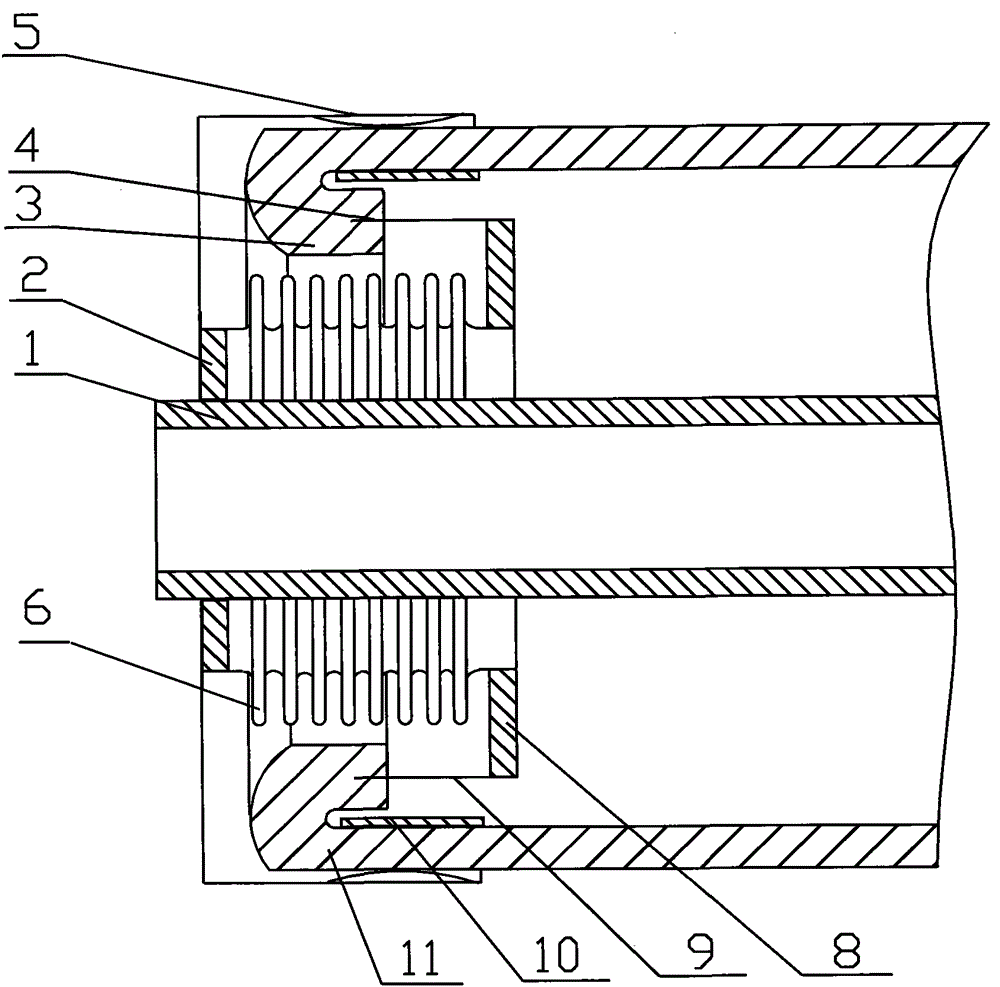

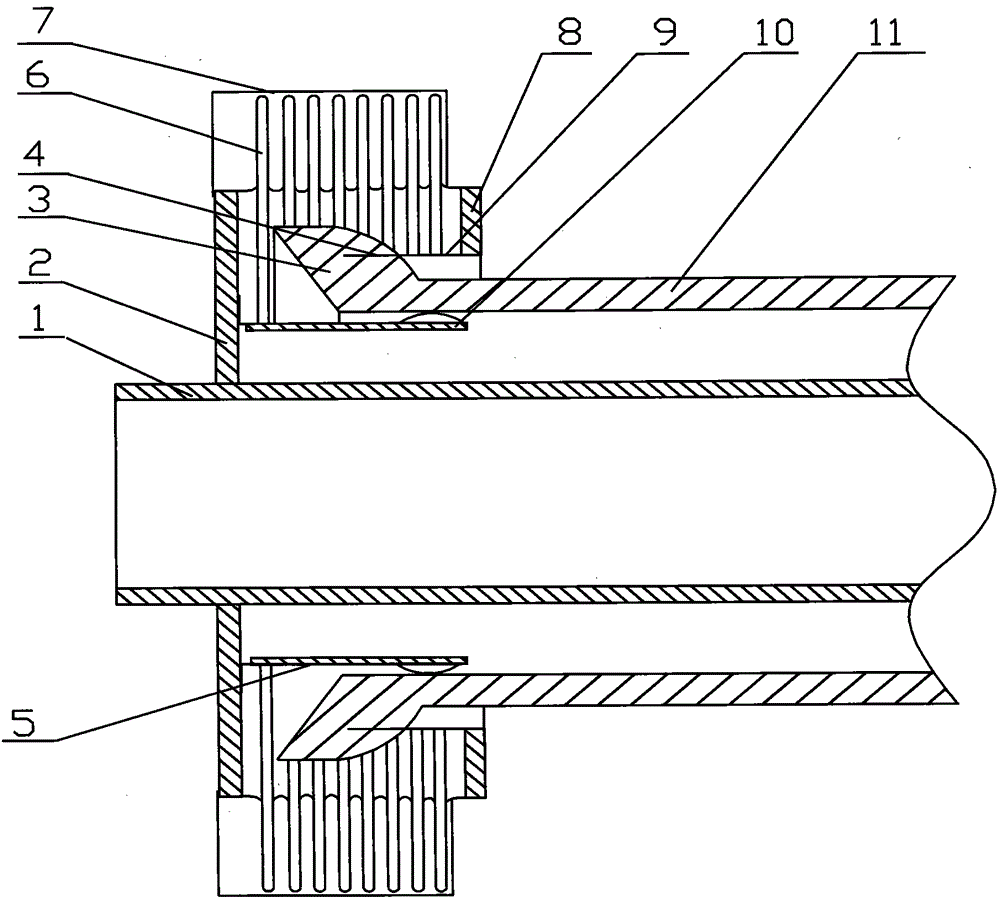

[0013] The following is a detailed description in conjunction with the accompanying drawings:

[0014] exist figure 1 Among them, the inverted glass tube 3 is composed of a glass tube with a larger diameter than the glass outer tube 11. One end of the inverted glass tube 3 is first melted or brazed with the thin-walled metal transition tube 9, and then concentric with the glass outer tube 11. Sleeve together, the two glass tube ends are welded or brazed to seal the connection; the wall thickness of the inverted glass tube 3 should be large or thickened at the metal sealing part, and the connection of the two glass tubes should also be thickened to ensure the strength of the force. ; The thin-walled metal transition tube 9 is folded back and connected with the bellows 6 through the connector 8, and the bellows 6 is connected with the coated metal inner tube 1 through the outer end cover 2; the thin-walled metal transition tube 9 can also be connected with the connector 8 One-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com