Shell-and-tube heat exchanger provided with blade type clapboards

A shell-and-tube heat exchanger and baffle technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of difficult processing, high manufacturing cost, complex structure, etc., to avoid flow Dead space, easy to manufacture and install, improved environmental effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

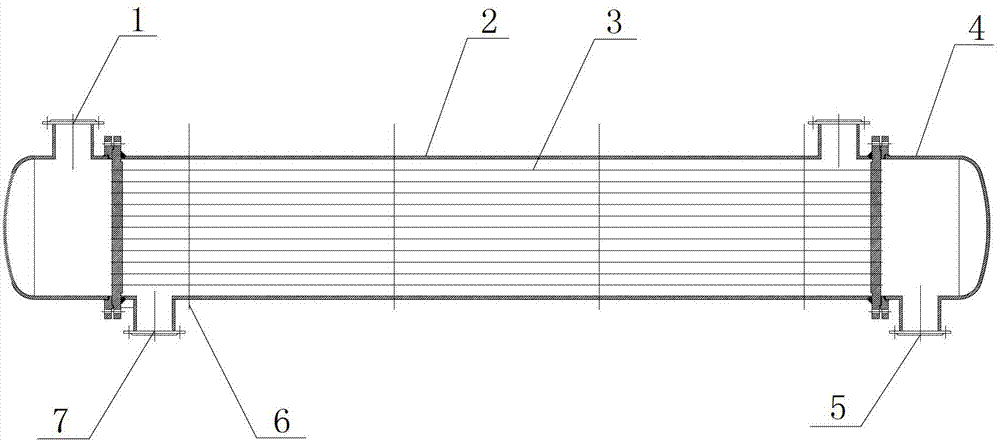

[0024] Such as figure 1 As shown in the figure, the vane-type baffle shell-and-tube heat exchanger includes a shell 2 and heat exchange tubes 3. A guide tube 7 is provided on both sides of the shell 2, and a cover 4 is provided at both ends of the shell 2. The cover 4 is respectively provided with a shell-side inlet 1 and a shell-side outlet 5 , and fan-blade partitions 6 are installed between the heat exchange tubes 3 .

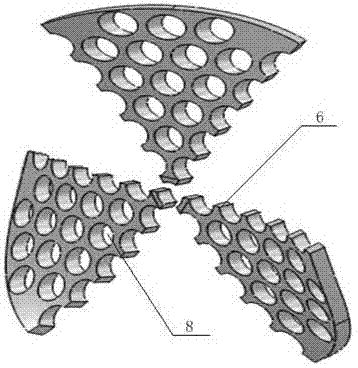

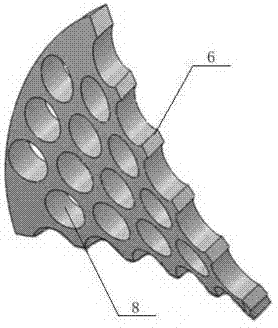

[0025] Such as Figure 2-5 As shown, a plurality of through holes 8 are provided on the blade-shaped partition 6 , and the heat exchange tubes 3 pass through the through holes 8 and are fixed in the casing 2 .

[0026] The fluid enters the heat exchanger through the shell-side inlet, and passes through the guide tubes at both ends of the shell, so that the shell-side fluid sweeps the tube bundle longitudinally on the one hand, and changes the flow direction repeatedly on the other hand, thereby enhancing heat transfer.

Embodiment 2

[0028] On the basis of Embodiment 1, the outer diameter of the fan-shaped partition 6 is the same as the inner diameter of the shell 2 , and there is a gap between the through hole 8 and the heat exchange tube 3 . Let the fluid pass through enough gaps, reduce the flow dead zone, reduce the shell side pressure, and inhibit the accumulation and precipitation of fluid dirt.

Embodiment 3

[0030] On the basis of Examples 1 and 2, such as figure 2 , Figure 4 , Figure 5 As shown, the fan-shaped partition 6 is composed of 3 fan-shaped partitions of equal size, the central angle of the fan-shaped partition is 60 degrees, and the 3 fan-shaped partitions of the fan-blade partition 6 form the same angle with the vertical direction, 3 The angle between the first fan-shaped partition and the vertical direction is 10 degrees, and the blade-shaped partitions 6 are placed alternately. The latter partition rotates clockwise at the same angle relative to the previous partition, and the rotation angle of the fan-shaped partitions 6 is 60 degrees. .

[0031] The fan-blade partitions are arranged alternately, and the difference between two adjacent partitions is the same angle, that is, the latter partition rotates clockwise around the center by the same angle relative to the previous partition, and so on. The staggered position of each fan-shaped partition is used to orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com