Device and method for testing diffusion performance of oil-gas components in pore medium

A technology of diffusion performance and porous media, which is applied in the field of experimental devices for the diffusion performance of oil and gas components in porous media, which can solve the problems of lag in the test process, inability to control the timing of contact between two fluids, and inability to measure static diffusion properties, and achieve measurement accuracy. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

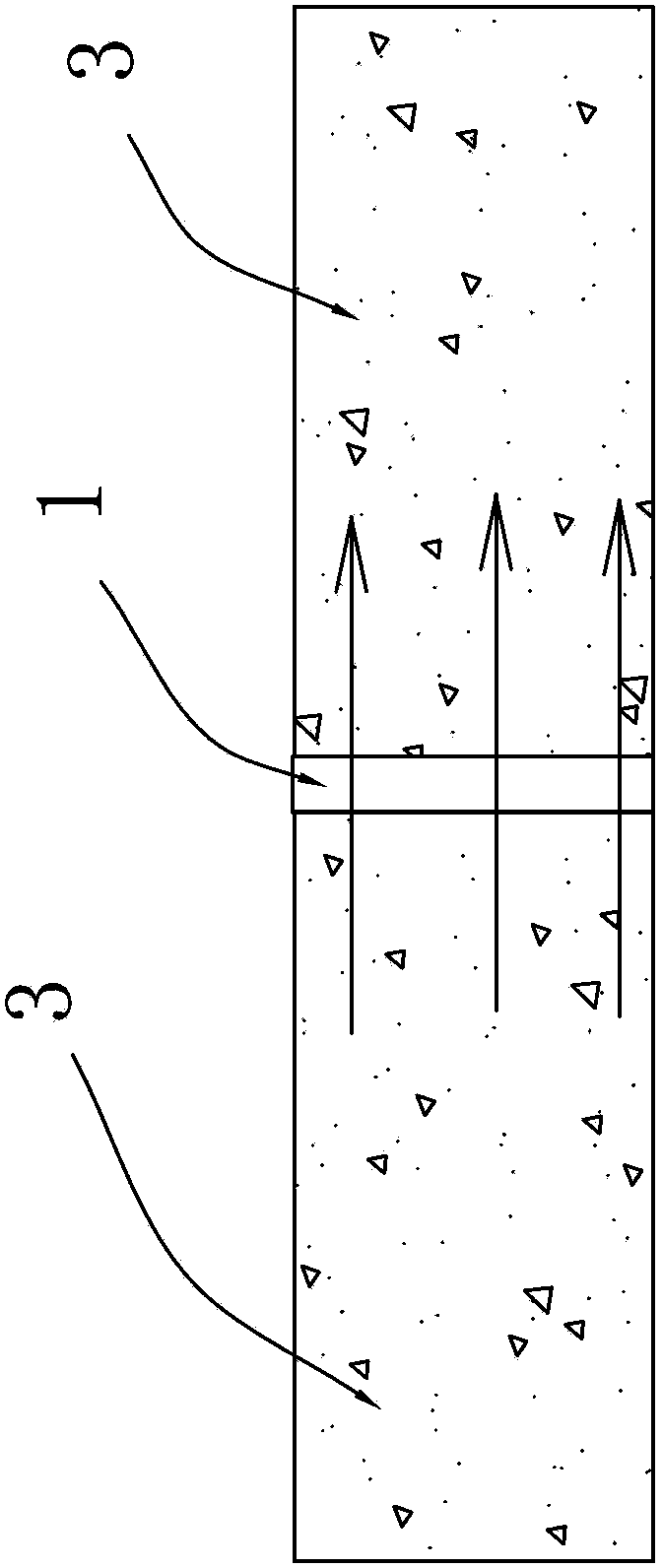

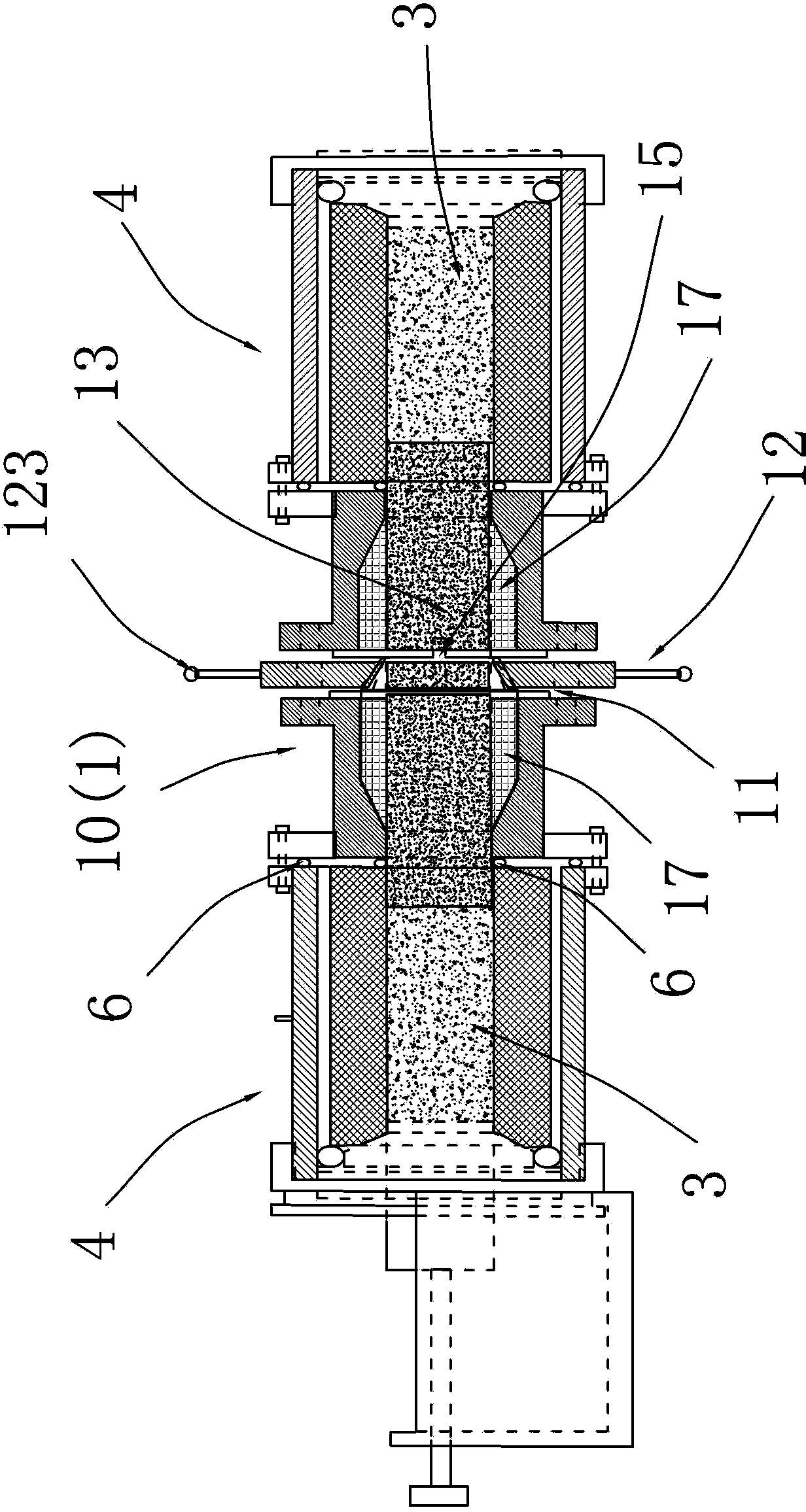

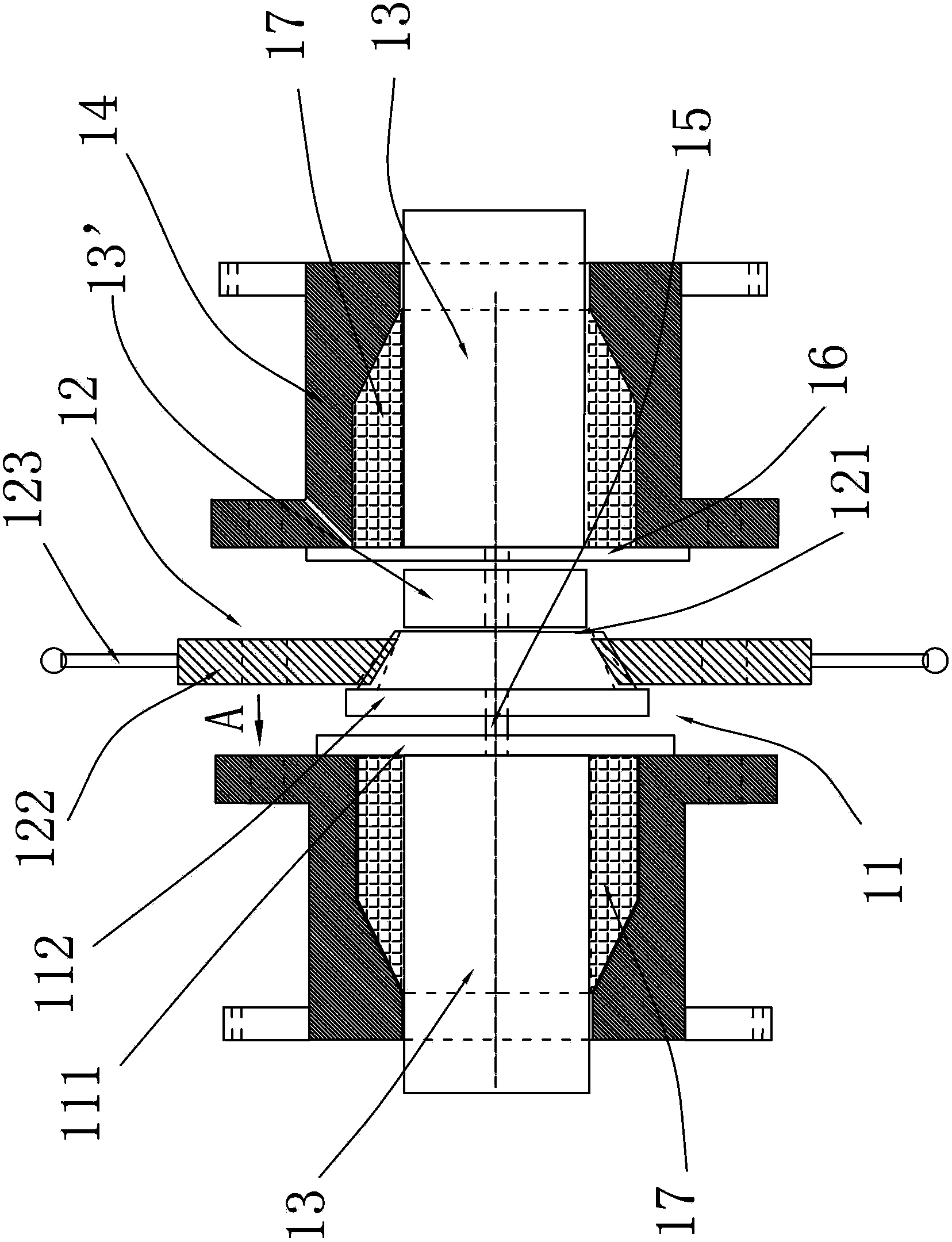

[0102] The same experiment was compared with the conventional diffusion performance experimental method. The content of the experiment: test the kerosene and CO at 60°C and 5MPa 2 The component diffusion velocity of 1 is filled with sandstone on both sides of the connecting valve 1 to form a sandstone model with a pore structure, i.e. the test core 3. The total length of the physical model (test core 3) is 5cm and the diameter is 25mm. 1 measurement point, located in the middle of the rock core. The experimental operation process is briefly described as follows:

[0103] ①The conventional method connects isothermal and isobaric oil samples and gas samples on both sides of the core holder after vacuuming; at the same time, the inlet valves on both sides of the core holder are opened, and the oil and gas enter the core at a constant pressure at the same time, and the valves on both sides are closed. Stabilize for 10 minutes; regularly take gas samples to analyze CO 2 content. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com