Two-optical-path cuvette structure

A cuvettes and optical path technology, applied in the direction of material analysis, measuring devices, instruments, etc. by optical means, can solve the problems of long test time, complex analysis steps, poor versatility of cuvettes, etc., and achieve good versatility. , the analysis steps are simple, the effect of shortening the test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

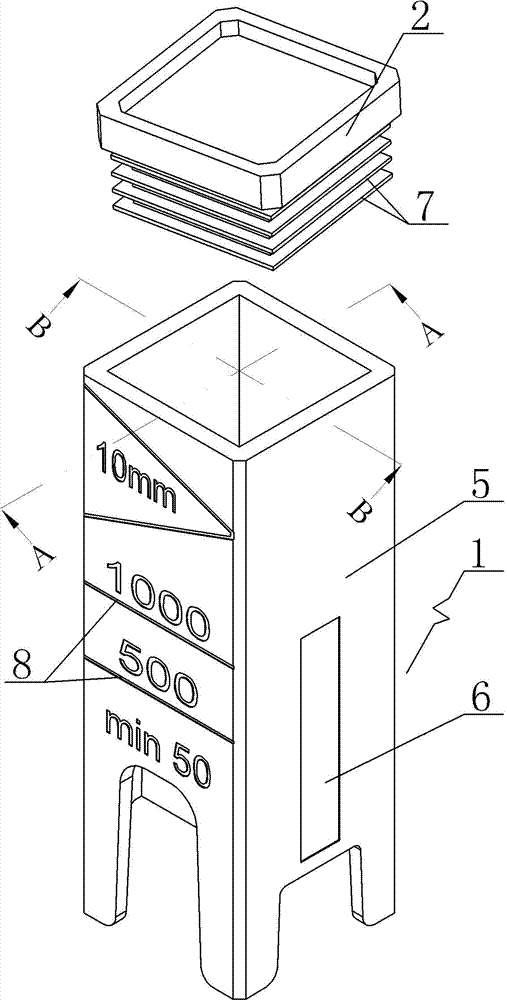

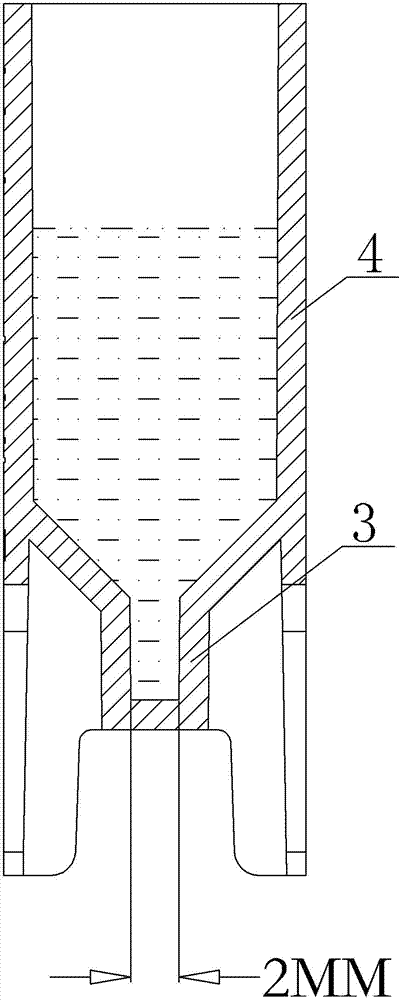

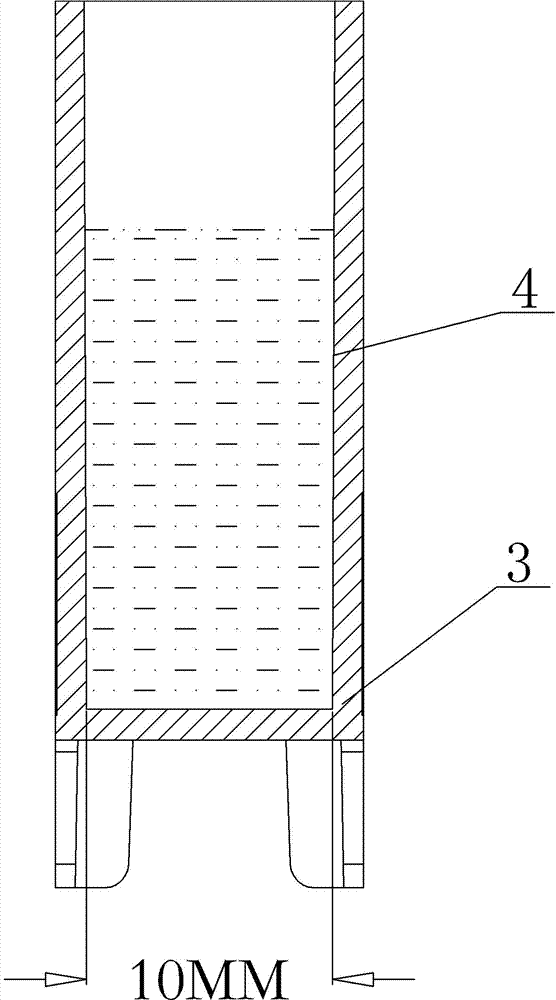

[0010] See figure 1 , figure 2 , image 3 , which includes a cuvette body 1, an upper cover 2, the upper cover 2 is mounted on the inner edge surface of the cuvette body 1, the cavity of the cuvette body 1 is a lower narrow strip structure 3, and an upper wide mouth structure 4, The upper end of the lower narrow strip structure 3 smoothly transitions to the lower end of the upper wide mouth structure 4, the inner cavity of the lower narrow strip structure 3 has a width of 10MM and a thickness of 2MM, and the inner cavity of the upper wide mouth structure 4 has a thickness of 10MM and a width of 10MM. The surface corresponding to the thickness 2MM of the lower narrow strip structure 3 of the cuvette body 1 is the light-transmitting surface 5, and the light-transmitting surface 6 of the light-transmitting surface 5 of the cuvette body 1 is a concave transparent structure, and the light-transmitting surface 6 The height is higher than the height of the lower narrow strip struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com