Method for measuring concentration of passivation tank liquid for galvanization

A passivation tank and passivation solution technology, which is applied in the measurement of phase influence characteristics, metal material coating process, etc., can solve the problem of long test period of chemical analysis method, large measurement error, and inability to meet the 60-minute replenishment of passivation bath solution. It can achieve the effect of fast detection, high accuracy and small detection error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: The method for measuring the concentration of the electroplating passivation bath adopts the following measuring steps.

[0024] (1) Configuration standard solution: Pipette 6.0, 6.5, 7.0, 7.5, 8.0ml of SurTec668 (produced by SurTec Metal Surface Treatment Technology (Hangzhou) Co., Ltd.) passivator into 5 100ml volumetric flasks, and dilute Shake at a constant volume to obtain a standard solution with the volume concentration of SurTec668 passivating agent of 6.0%, 6.5%, 7.0%, 7.5%, and 8.0% respectively;

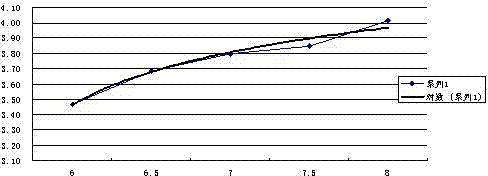

[0025] (2) Detect the configured standard solution with a refractometer, and perform repeated measurements to determine the refractive index, and draw a curve according to the change of the refractive index at different concentrations; the concentration-refractive index change curve is as follows figure 1 As shown, the refractive index control range is 3.5~4.0;

[0026] (3) Take the passivation bath to be measured and use a refractometer to determine its refr...

Embodiment 2

[0027] Embodiment 2: The method for measuring the concentration of the electroplating passivation bath adopts the following measuring steps.

[0028] (1) Configure standard solution: mix SurTec668 and SurTec680LC (produced by SurTec Metal Surface Treatment Technology (Hangzhou) Co., Ltd.) at a volume ratio of 2:1, and pipette 3.0, 4.0, 4.5, 5.0 respectively , 6.0ml of mixed passivator into 5 100ml volumetric flasks, dilute to a constant volume and shake well. Calculate according to the concentration of the mixed passivation agent, and get the standard solution with volume concentration of 3.0%, 4.0%, 4.5%, 5.0%, 6.0% respectively;

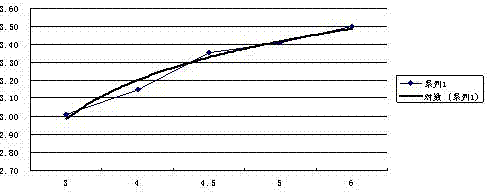

[0029] (2) Detect the configured standard solution with a refractometer, and perform repeated measurements to determine the refractive index, and draw a curve according to the change of the refractive index at different concentrations; the concentration-refractive index change curve is as follows figure 2 As shown, the refractive index control range i...

Embodiment 3

[0031] Embodiment 3: The method for measuring the concentration of the electroplating passivation bath adopts the following measuring steps.

[0032] (1) Configuration standard solution: Pipette 6.0, 6.5, 7.0, 7.5, 8.0ml of SurTec668 passivation agent into 5 100ml volumetric flasks, dilute to a constant volume and shake well to obtain the volume concentration of 668 passivation agent respectively. 6.0%, 6.5%, 7.0%, 7.5%, 8.0% standard solution;

[0033] (2) Detect the configured standard solution with a refractometer, and repeat the measurement to determine the refractive index, and draw a curve according to the change of the refractive index at different concentrations. The concentration-refractive index change curve is as follows figure 1 Shown

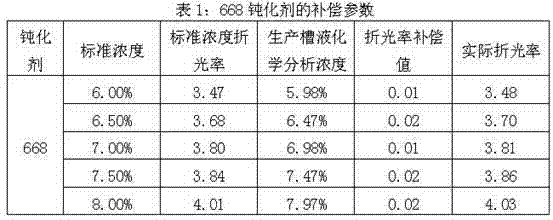

[0034] (3) Measure and compare the passivation solution in the industrial production process, verify the error between the experimental value and perform numerical compensation. The supplementary method is: a. The laboratory proportions th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com