Voltage detection device, system and method

A voltage detection method and voltage detection technology, applied in the field of electronics, can solve problems such as low reliability, normal chip business impact, and system failure to detect alarms, and achieve the effect of improving system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

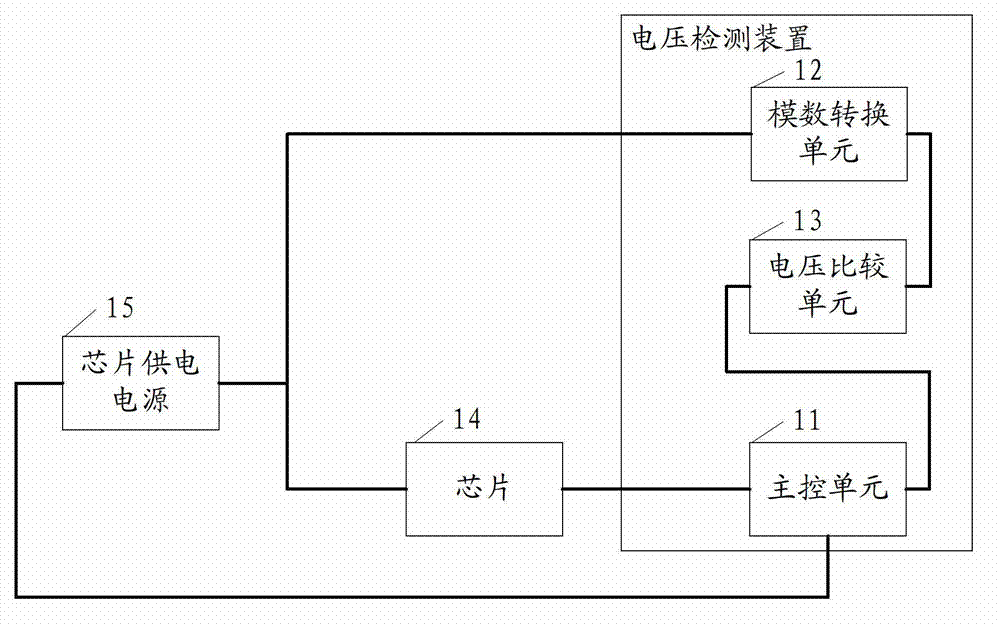

[0045] An embodiment of the present invention provides a voltage detection device, such as figure 1 As shown, it includes a main control unit 11 , an analog-to-digital conversion unit 12 and a voltage comparison unit 13 . in:

[0046] The main control unit 11 is connected with the chip 14, and is used to receive the real-time VID of the chip 14, convert the real-time VID of the chip 14 into the acceptable working voltage range of the chip 14 specified by the real-time VID, and accept the working voltage range of the chip 14 specified by the real-time VID. The voltage range is supplied to the voltage comparison unit 13 .

[0047] The analog-to-digital conversion unit 12 is connected to the chip power supply 15, and is used to receive the actual voltage analog signal provided by the chip power supply 15, convert the actual voltage analog signal into an actual voltage value, and provide the actual voltage value to the voltage A comparison unit 13 ; wherein, the chip power supply ...

Embodiment 2

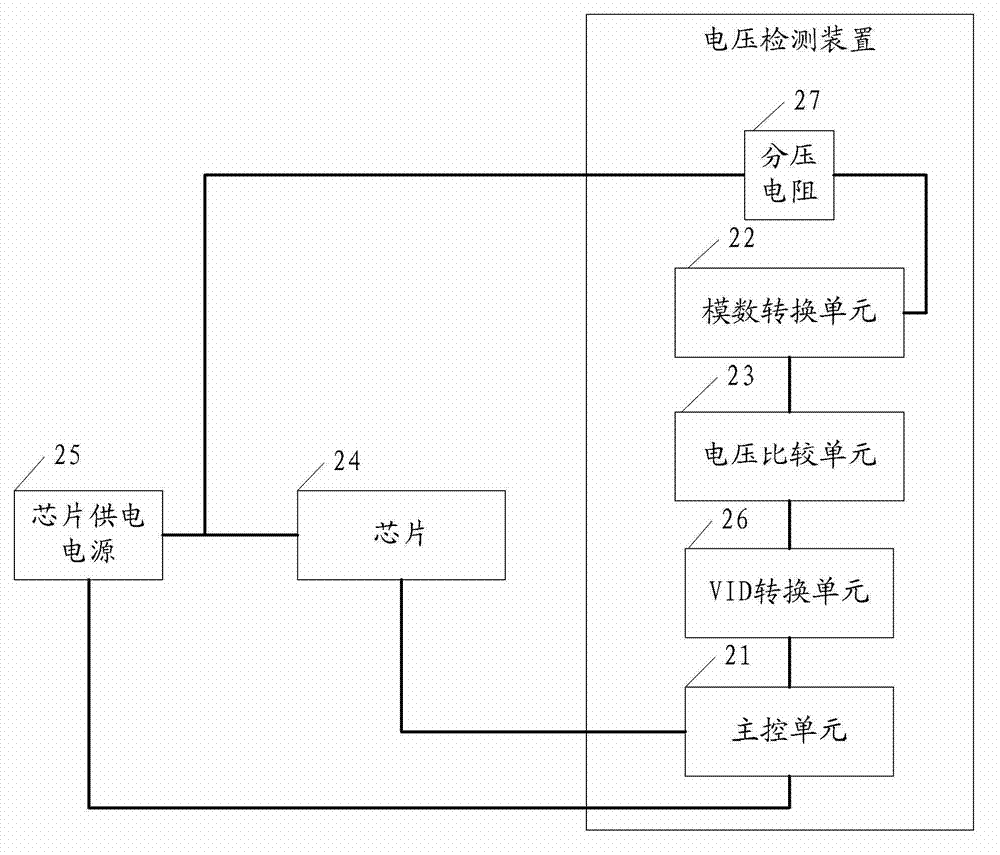

[0058] An embodiment of the present invention provides a voltage detection device, such as figure 2 As shown, the voltage detection device includes a main control unit 21 , an analog-to-digital conversion unit 22 , a voltage comparison unit 23 and a VID conversion unit 26 .

[0059] The main control unit 21 is connected to the chip 24 for receiving the real-time VID of the chip 24 and providing the real-time VID of the chip 24 to the VID converting unit 26 .

[0060] The analog-to-digital conversion unit 22 is connected to the chip power supply 25, and is used to receive the actual voltage analog signal provided by the chip power supply 25, convert the actual voltage analog signal into an actual voltage value, and provide the actual voltage value to the voltage A comparison unit 23 ; wherein, the chip power supply 25 is used to supply power to the chip 24 .

[0061] The VID conversion unit 26 is used to receive the real-time VID sent by the main control unit 21, convert the ...

Embodiment 3

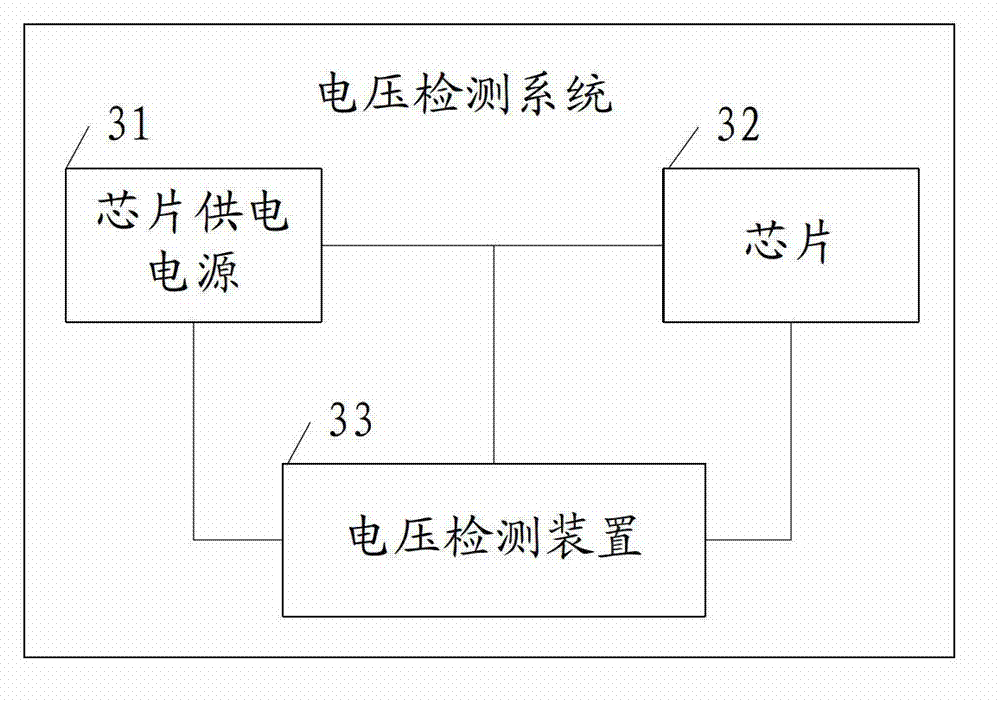

[0071] An embodiment of the present invention provides a voltage detection system, such as image 3 As shown, it includes: a chip 31 , a chip power supply 32 and the aforementioned voltage detection device 33 .

[0072] The chip power supply 32 is respectively connected to the chip 31 and the voltage detection device 33 to provide voltage for the chip 31 and the voltage detection device 33 .

[0073] The chip 31 is connected to the voltage detection device 33 and sends the real-time VID of the chip 31 to the voltage detection device 33 .

[0074] Among them, the chip power supply 32 provides actual voltages for the chip 31 and the voltage detection device 33 respectively, the chip 31 adjusts the real-time VID information according to its internal junction temperature and manufacturing process, and the voltage detection device 33 obtains the real-time VID information from the chip 31. In the voltage detection device 33, the actual voltage value is compared with the acceptable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com