Six-degree-of-freedom micro-motion worktable

A workbench, degree of freedom technology, used in microlithography exposure equipment, photolithographic process exposure devices, etc., can solve the problems of thick table body, poor structural integrity, large structural volume, etc., to reduce high-precision requirements and reduce parts. number, the effect of improving system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

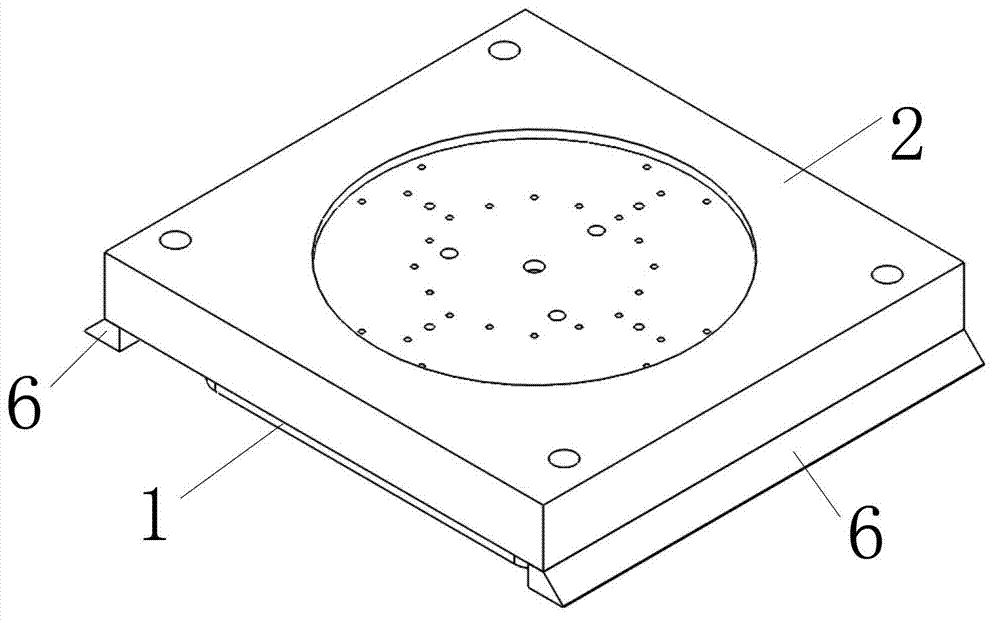

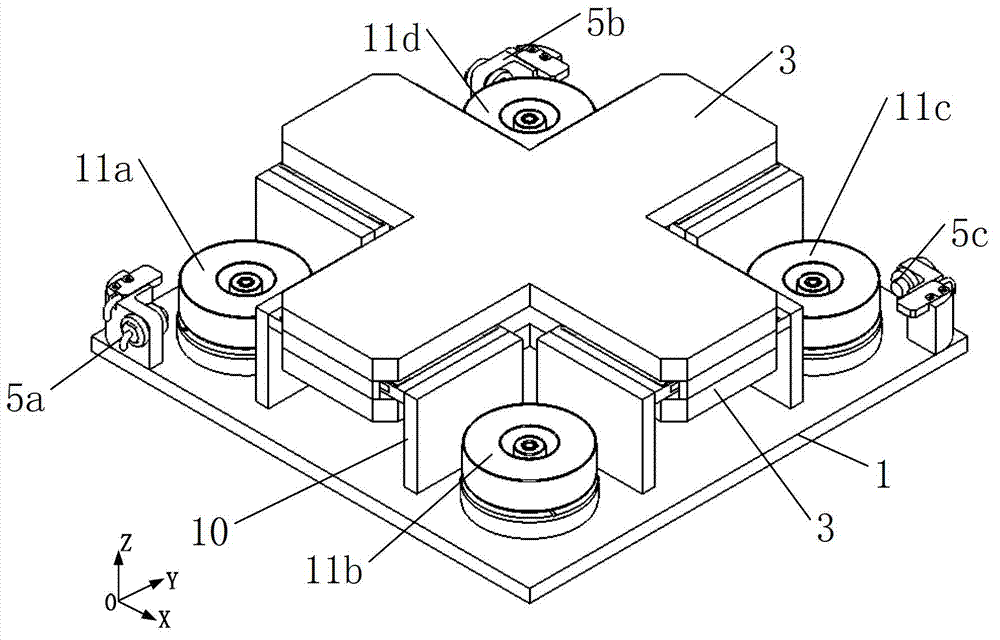

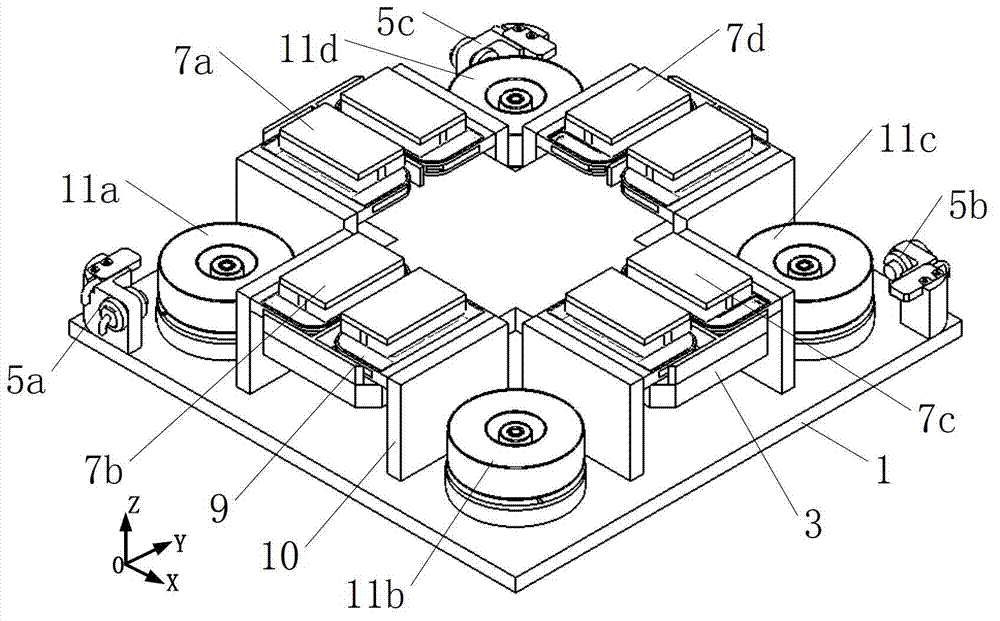

[0029] figure 1 , figure 2 with image 3 It is a three-dimensional structure diagram of a six-degree-of-freedom micro-motion workbench provided by the present invention. The micro-motion workbench includes four groups of the first type of electromagnetic force driving module, and each group of the first type of electromagnetic force driving module includes at least one electromagnetic force driving unit (if larger driving force is required, more than one can be used). In the example, the first type of electromagnetic force driving module uses two first type of electromagnetic force driving units 14, wherein the first group 7a of the first type of electromagnetic force driving module and the third group 7c of the first type of electromagnetic force driving module are The X axis is symmetrically arranged about the Y axis, and the second group 7b of the first electromagnetic force drive module and the fourth group 7d of the first electromagnetic force drive module are arranged sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com