Warehouse logistics management system and method

A warehousing logistics and management system technology, applied in logistics, data processing applications, instruments, etc., can solve the problems of being unable to accurately locate each bulk cargo, unable to accurately locate the goods in the warehouse, and unable to know the specific location of each batch of goods, etc. To achieve the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

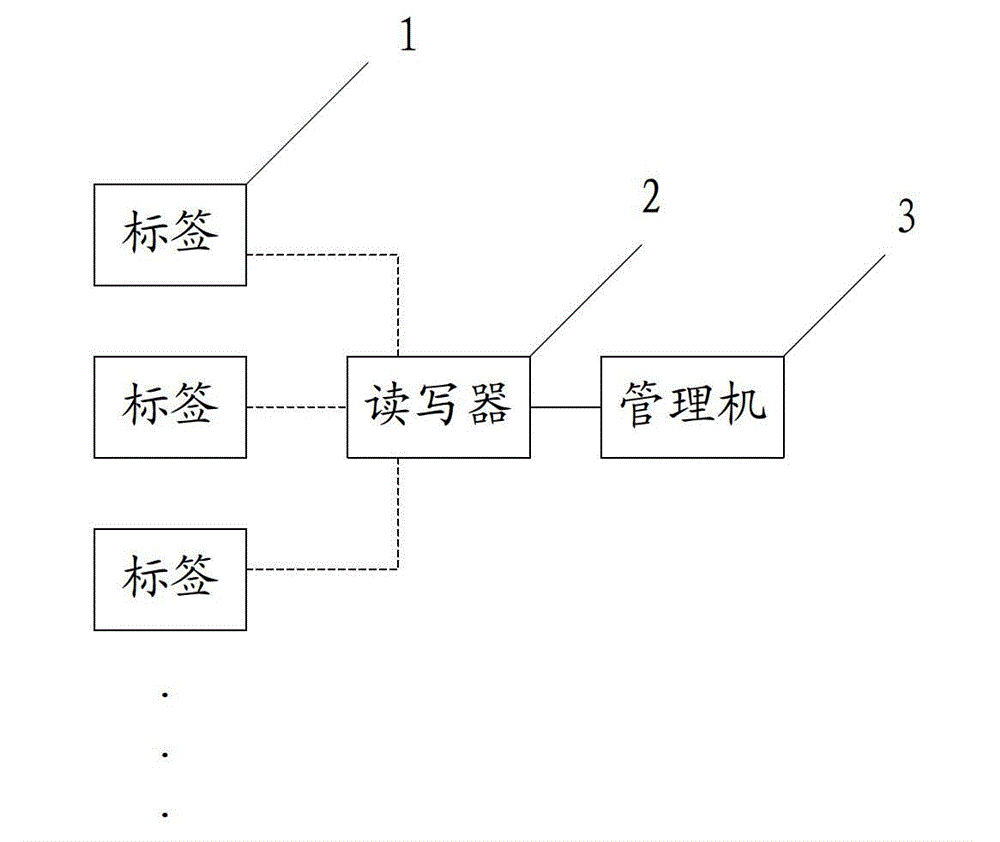

[0040] This embodiment provides a warehouse logistics management system, see figure 1 As shown, it includes tag 1, reader-writer 2 and management machine 3.

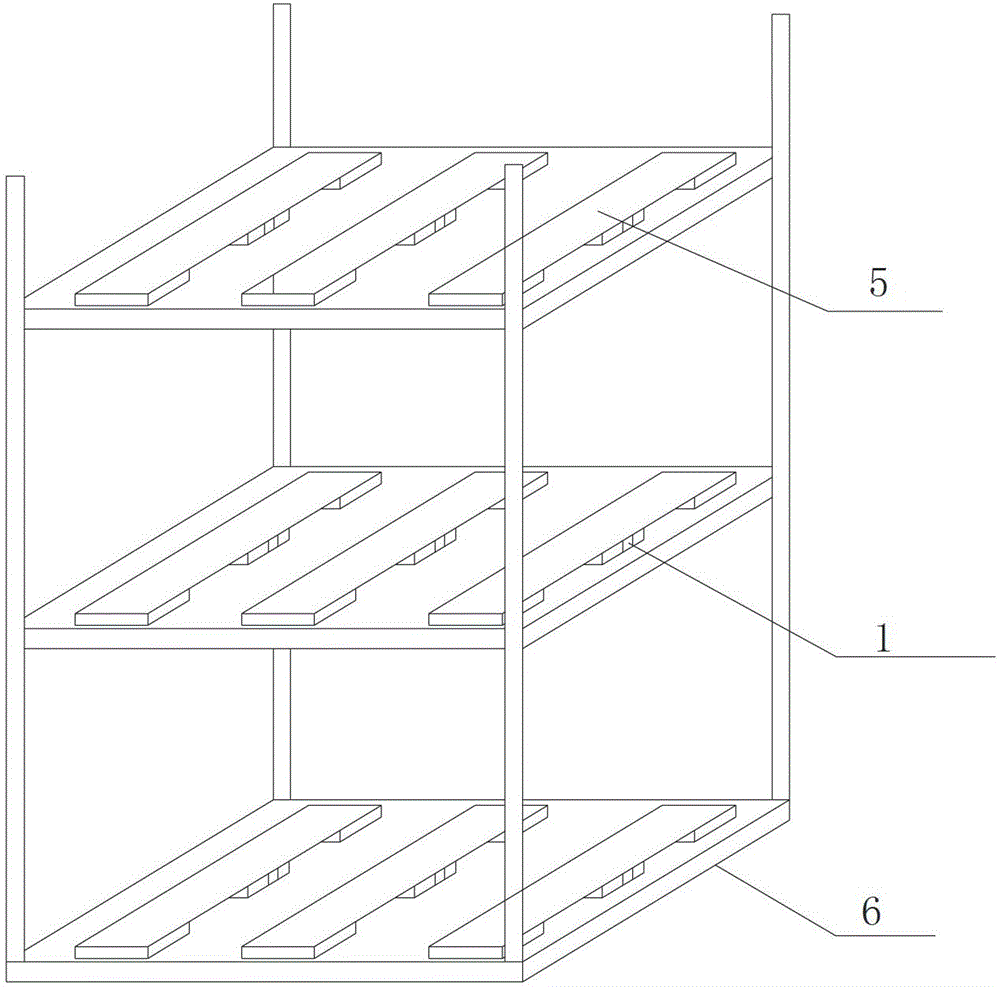

[0041] see figure 2 As shown, the label 1 is fixed on the tray 5 , and the tray 5 is placed on the shelf 6 . The unique code of the label 1 and the goods information corresponding to the goods on the pallet 5 are stored in the label 1 .

[0042] Preferably, the label 1 is fixed on the bottom of the tray 5, and may also be fixed on other positions of the tray 5, which can be implemented by those skilled in the art according to the actual situation, and is not limited in this embodiment.

[0043] Preferably, one label 1 should be fixed at the bottom of each tray 5 , that is, there is a one-to-one correspondence between the trays 5 and the labels 1 . Since the pallet 5 is a relatively small storage unit in the warehouse, the tracking and positioning of the pallet 5 can be realized by setting the label 1 on the pallet 5 ...

Embodiment 2

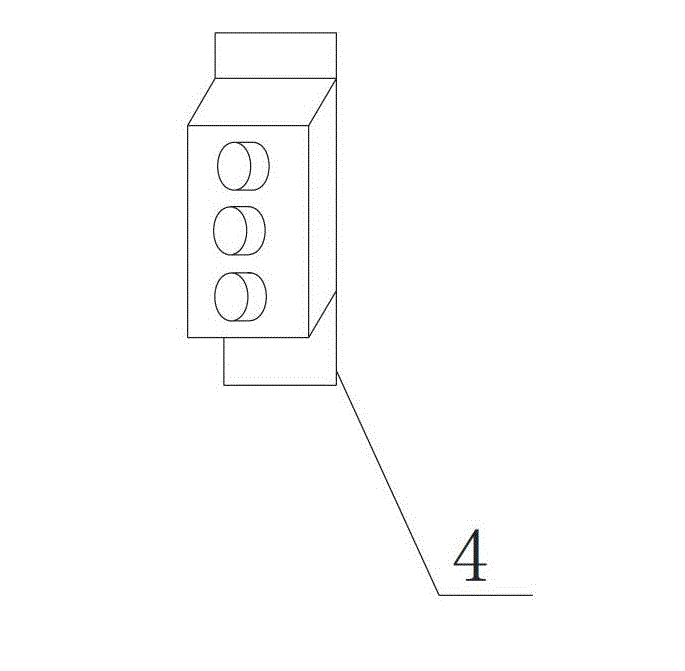

[0054] This embodiment provides a warehouse logistics management system, including a tag 1 , a reader 2 , a management machine 3 and a signal device 4 .

[0055] The connection relationship between the tag 1, the reader-writer 2, and the management machine 3 can be found in Embodiment 1, which will not be repeated in this embodiment.

[0056] The signal device 4 includes a plurality of signal lights and / or whistle units, and each signal light and / or whistle means represents a kind of cargo storage information.

[0057] see image 3 As shown, as a possible implementation, the signal device 4 includes more than two signal lights, which can be represented by different colors. For example, when the goods are placed correctly, the green signal light is ordered to be on. , then order the red signal lamp to be on, and more preferably, the signal lamp can also be equipped with a whistle at the same time. At the same time, when the administrator transports the goods, he can also orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com