Adhesive sticker label capable of being subjected to laser printing and production process for adhesive sticker label

A laser printing and production process technology, applied in the directions of sealing, layered products, instruments, etc., can solve the problems of laser printer or copier damage, affecting the quality of self-adhesive printing, etc., and achieve the effect of improving service life and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

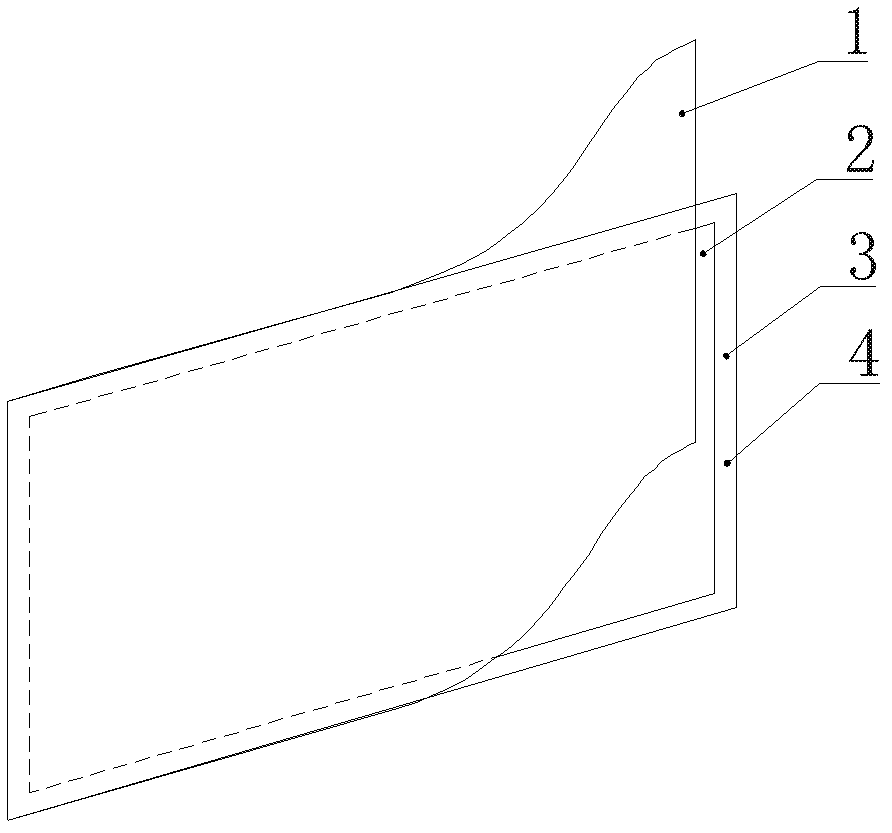

[0037] see Figure 1 to Figure 4 , a self-adhesive label that can be printed by laser in the present invention includes a face paper 1, a bottom paper 3 and an adhesive layer 2 between the two, and it is characterized in that the surroundings of the face paper 1 and the bottom paper 3 are Leave the non-adhesive edge 4 (the edge without the adhesive layer 2) that is 0.1-6mm in width, that is, the edges of the adhesive layer 2 are 0.1-6mm larger than the surroundings of the surface paper 1 and the bottom paper 3. Top paper 1 is the same size as bottom paper 3.

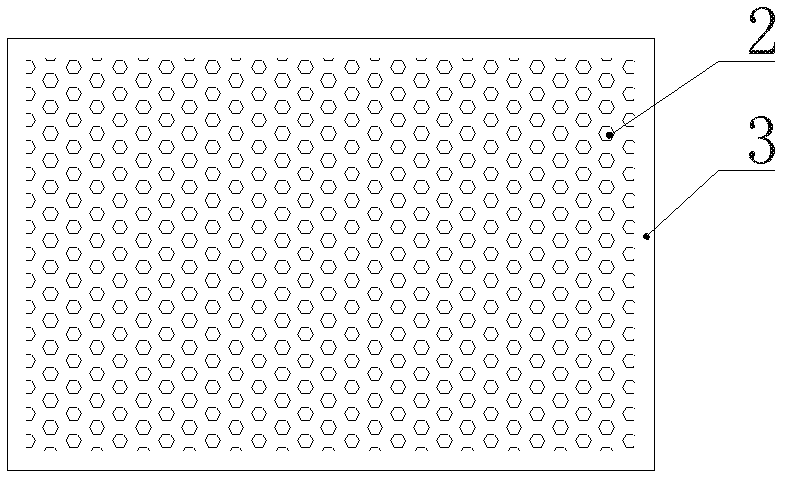

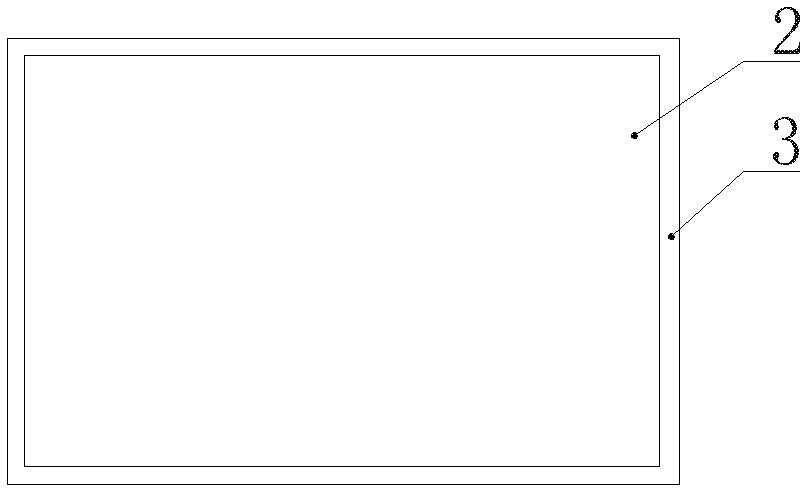

[0038] Described adhesive layer 2 is dotted distribution (as figure 2 shown), continuous distribution (such as image 3 shown) or grid distribution (such as Figure 4 shown). There are two forms of grid distribution, one is that the grid lines are blank strips without glue layers, and the rectangular areas separated by grid lines have glue layers; the other is the opposite of the first one, and the grid lines have g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com