A kind of manufacturing method of Damascus structure

A production method and technology of nitride film, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as difficulties in lithography rework, and achieve the effects of stable process, easy control of process, and simple and easy control of process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Some typical embodiments embodying the features and advantages of the present invention will be described in detail in the description in the following paragraphs. It should be understood that the invention is capable of various changes in different examples without departing from the scope of the invention, and that the descriptions and illustrations therein are illustrative in nature rather than limiting the invention.

[0040] The above and other technical features and beneficial effects will be combined with the embodiments and the accompanying Figure 2-12 A method for fabricating a Damascus structure of the present invention will be described in detail.

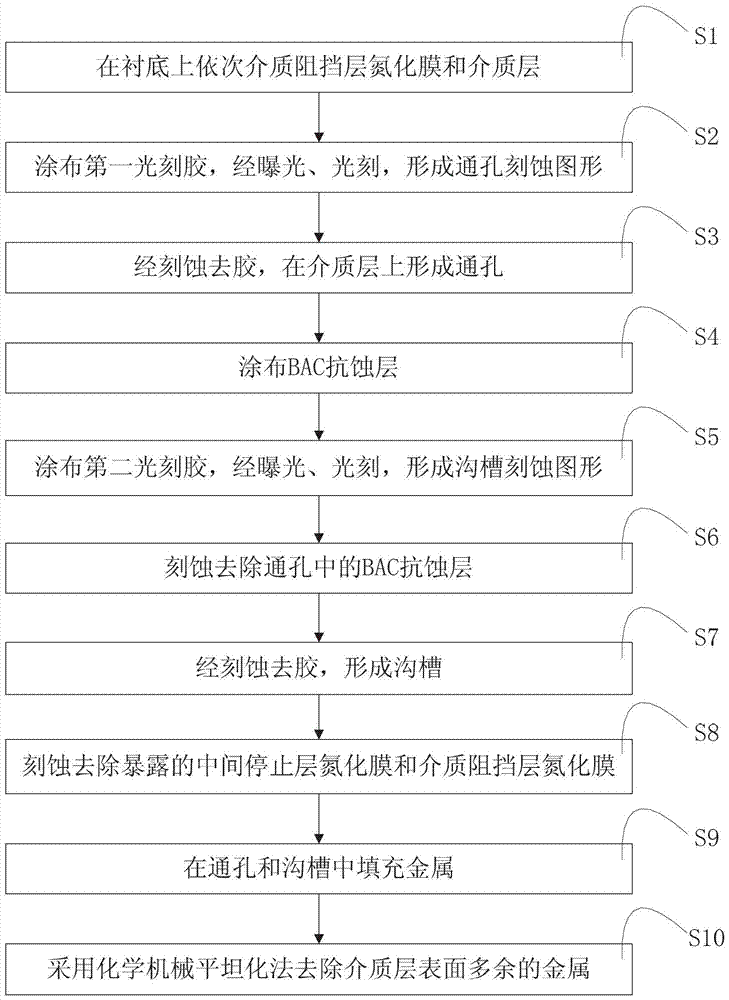

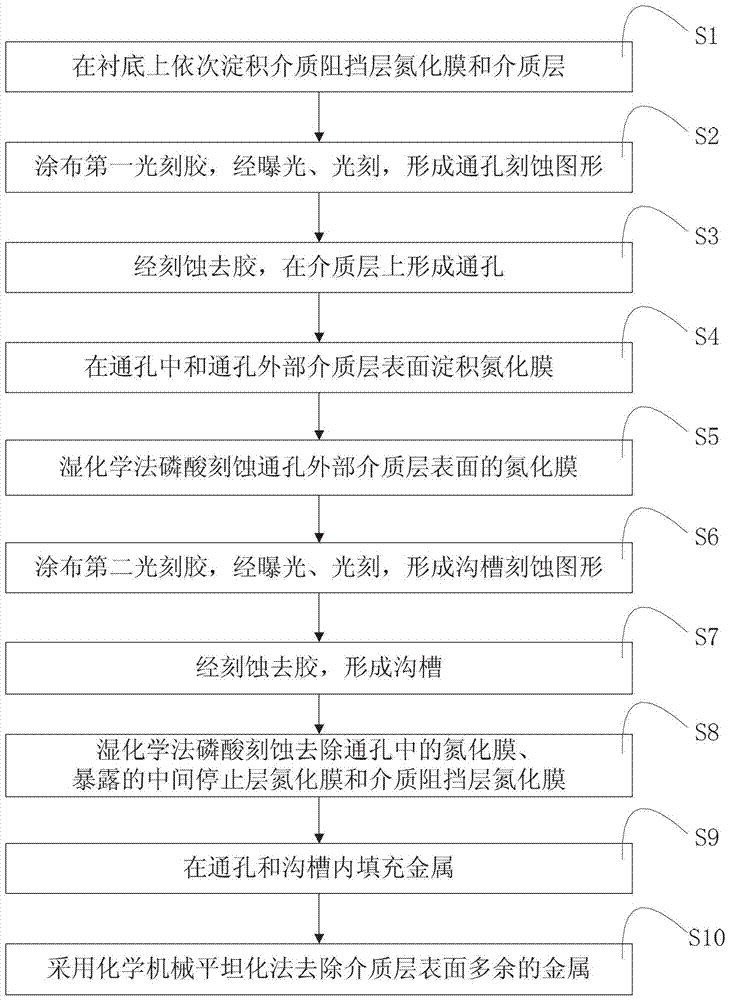

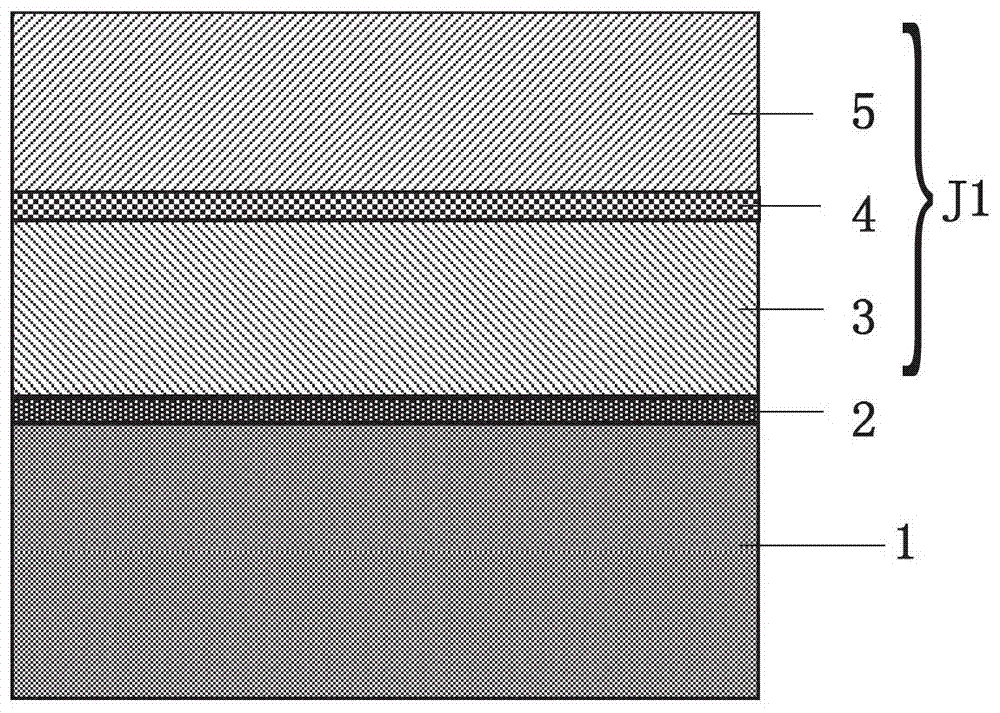

[0041] figure 2 It is a schematic flow chart of a preferred embodiment of a method for fabricating a Damascene structure of the present invention. In this embodiment, a method for fabricating a damascene structure includes steps S01 to S10, and steps S01 to S10 are respectively carried out by attaching Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com