A clamp for installing wire clamps for live work

A technology for live work and installation of clamps, applied to pliers, overhead line/cable equipment, manufacturing tools, etc., to achieve the effect of short working time and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

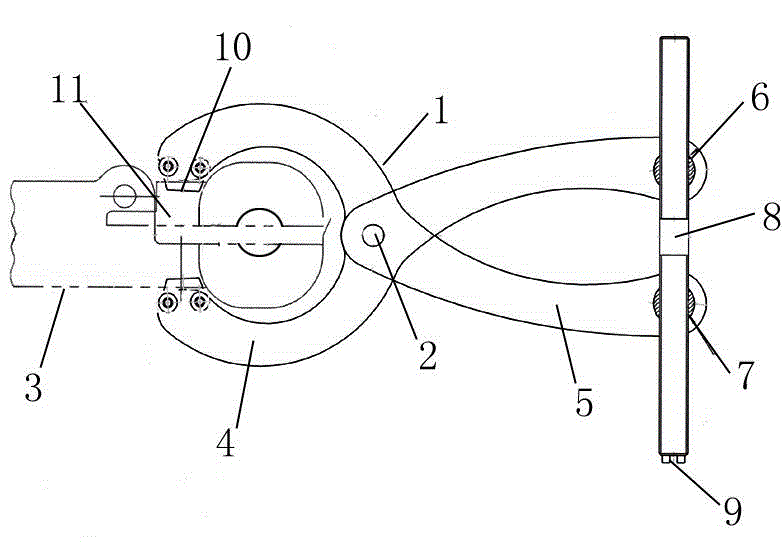

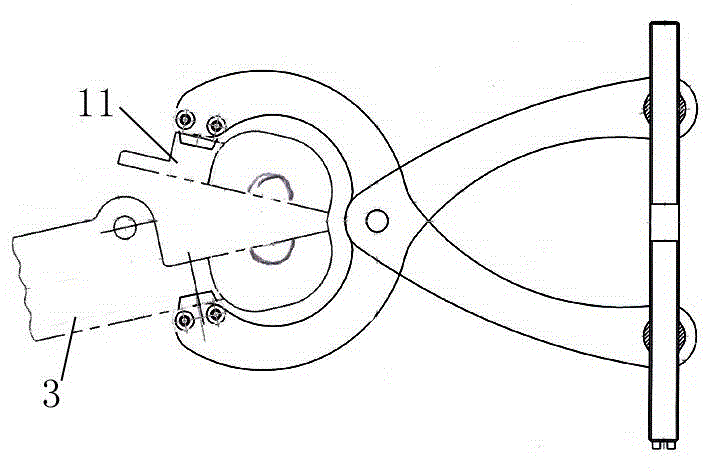

[0013] The present invention mainly consists of the following structures: a 2.0-meter reinforced insulating operating rod, the length of which can be selected according to the voltage level of the transmission line; a 0.5-meter special non-slip corrugated insulating rod operating handle, and a special joint matched with the clamp.

[0014] It is composed of rotating double screw rod (positive and negative thread structure), clamp head positioning nylon column, screw joint, etc. Special clamp for wire end clamp: when in use, it is also equipped with a special tool for pin installation, which consists of an operating rod joint , Pin fixed rubber ring and other combinations.

[0015] For the new device of wire clamp for live installation, it includes two tools for clamping the wire end clamp and pin in place, so that the complicated process can be completed in 2 minutes with the effective cooperation of two people, and the wire side installation can be completed effici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com