Processing method of through holes of printed circuit board (PCB) and through hole structure

A technology of a PCB board and a processing method is applied in the field of a PCB board through-hole processing method and through-hole structure for improving signal quality, which can solve the problems of large parasitic capacitance and affect the quality of high-speed signals, and achieves reduction of parasitic capacitance, low processing cost, The effect of improving transmission quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

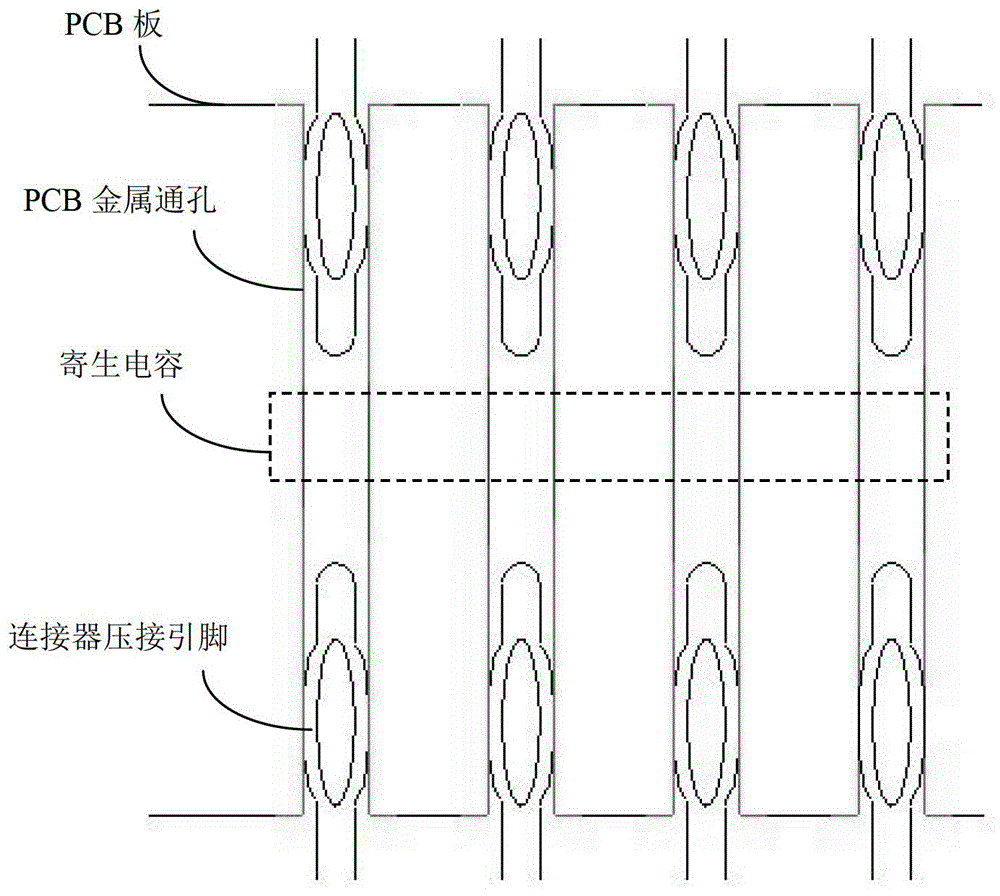

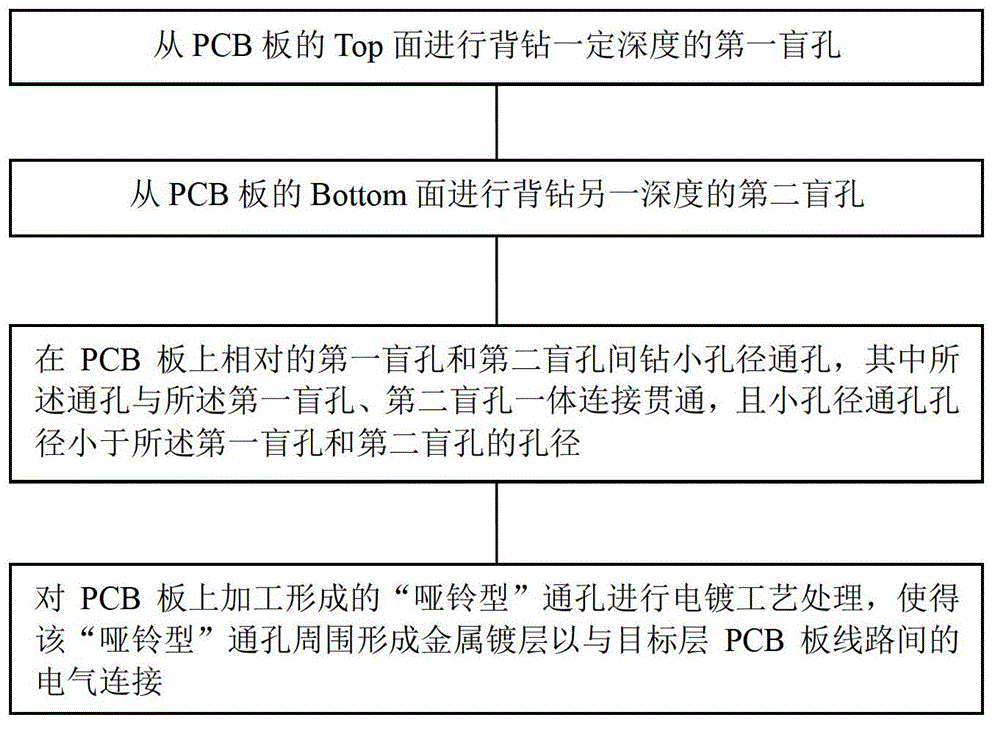

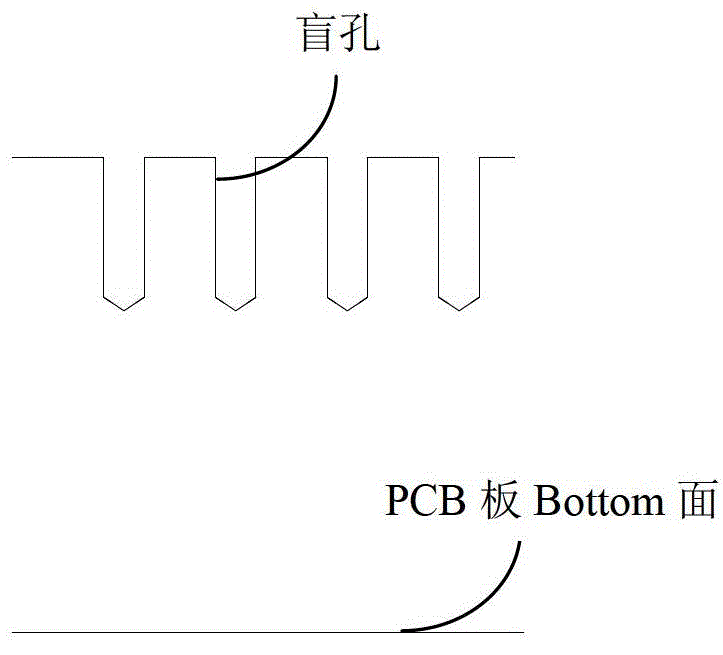

[0026] In order to achieve the purpose of the present invention, the core idea adopted in the present invention is: after the crimping device is pressed in the metal through hole of the PCB board in the existing scheme, a large parasitic capacitance is generated in the through hole, which in turn affects the high speed in the PCB board. The condition of the signal quality. The present invention processes the through-hole structure of the PCB board into a "dumbbell-shaped" structure. After the crimping device is pressed against the PCB, since the hole diameter between the crimping pins is much smaller than that of the through hole in the existing solution, the parasitic capacitance generated is very small, and the signal quality of the PCB is improved. The invention also provides a processing method for processing the "dumbbell-shaped" through-hole structure.

[0027] In order to make the technical solution of the present invention clearer and clearer, it will be described in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com