Method for manufacturing a bending transducer, a micro pump and a micro valve, micro pump and micro valve

一种换能器、微型阀的技术,应用在泵、阀装置、机器/发动机等方向,能够解决无法实现常闭阀致密性要求等问题,达到减少去极化风险、减少闭死容积、高行程容积的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

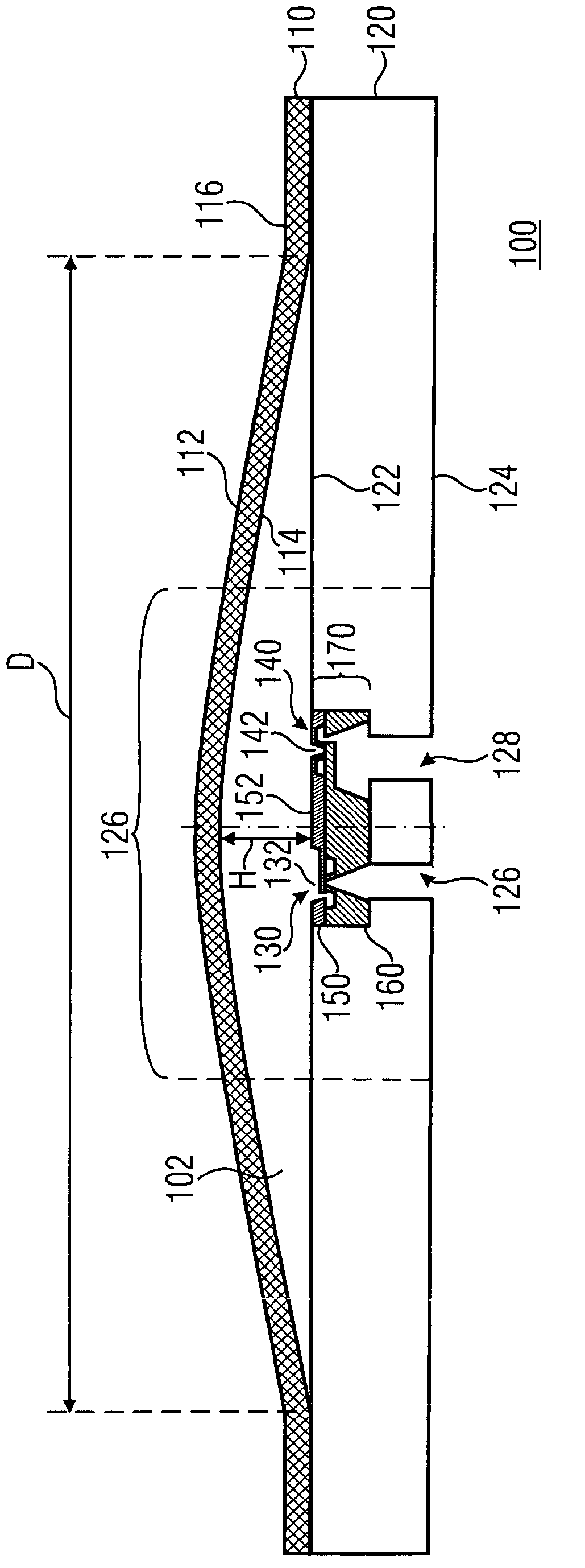

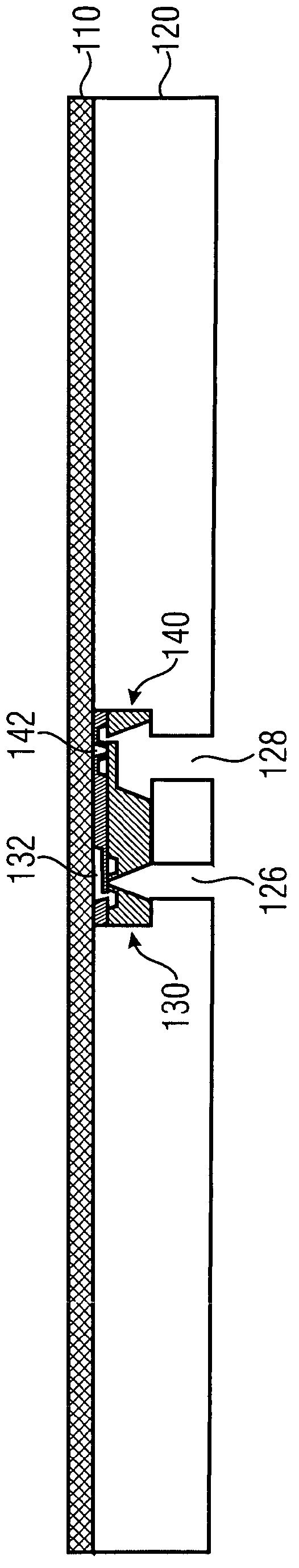

[0129]Other embodiments may include pump bodies having integrally formed valve inlet and valve outlet structures 130 and 140 comprising materials such as steel, stainless steel or spring stainless steel, synthetic materials or polymers, wherein , these pump bodies may comprise a single layer or multiple layers to form a valve structure. Therefore, further embodiments of the micropump may include a pump body and a pump diaphragm made of metal, synthetic material, or polymer, or stacks thereof. Making pump bodies and pump diaphragms from metal or polymers is less expensive to produce and provides higher elasticity, eg, lower Young's modulus, than silicon pump bodies and pump diaphragms.

[0130] Other embodiments of the present invention provide micropumps having a driven diaphragm, wherein the driven diaphragm moves between an upwardly pre-bulged or pre-twisted position and a substantially planar position, wherein the pump diaphragm disposed facing the pump body The unevenness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com