Blending device and method for multiple granular materials

A granular material and mixing technology, applied in mixing methods, chemical instruments and methods, mixers, etc., can solve problems such as low efficiency, material damage, affecting material mixing, etc., to avoid internal dead ends, improve efficiency, and improve uniformity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

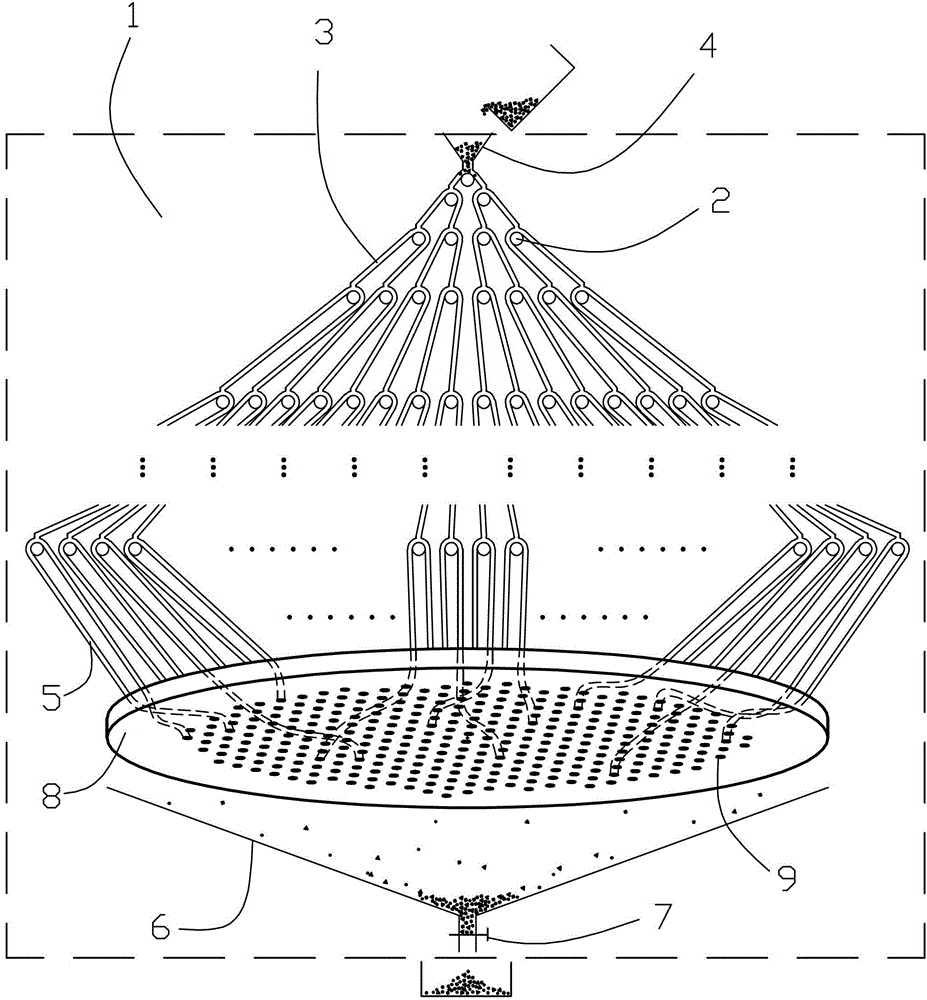

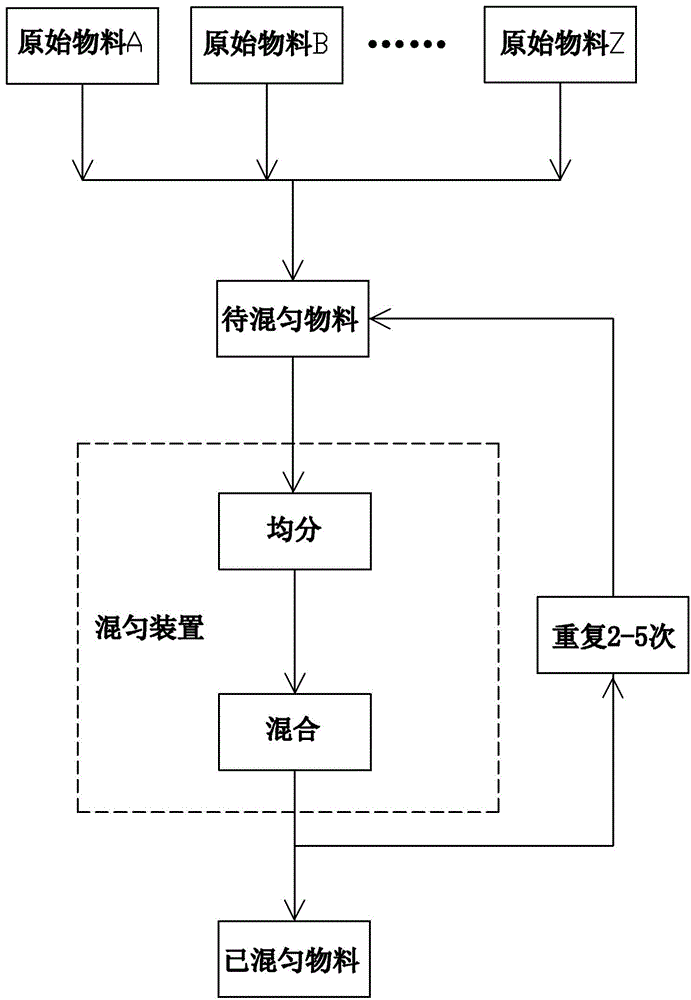

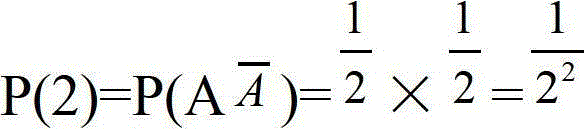

[0025] In this embodiment, a variety of granular material mixing devices, such as figure 1 As shown, the mixing device is composed of two parts: an evenly distributing part and a mixing part. The evenly distributing part includes several rows of cylinders 2 that increase in multiples and a pipeline 3 that guides materials to fall. The cylinder increases in multiples of 2. , the first row is 1, the second row is 2, the third row is 4, and so on, the last row is 2 n-1 The pillars increase row by row from top to bottom, and each row of pillars is centered, and the pillars are evenly spaced. The upper end of the pipeline has a feed port 4, which is funnel-shaped. The pipeline extends to the top of the column and is divided into two branches. The two branches bypass the two sides of the column and extend to the front of the next row of columns. Above, repeat until after the last row of cylinders, the lower end of the pipeline is distributed to form a discharge port 5, the pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com