Punching method for improving flanging capability of sheet

A technology of flanging and punching, which is used in perforating tools, metal processing equipment, forming tools, etc., can solve problems such as reducing efficiency, increasing processes, and reducing material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

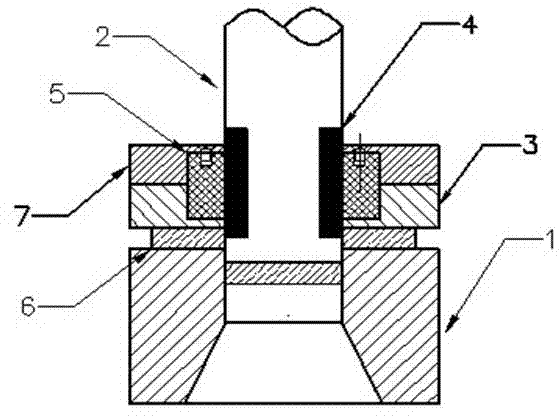

Image

Examples

Embodiment 1

[0032] Embodiment 1: The sheet metal is a martensitic dual-phase steel, and its mechanical properties are as follows:

[0033] Yield strength: 435 MPa; ultimate strength: 786Mpa; elongation: 24%;

[0034] Sheet thickness: 2mm; initial inner hole diameter on the blank: 10mm;

[0035] The flanging performance is measured by the flanging coefficient K:

[0036] K=d / D;

[0037] In the formula: d----initial inner hole diameter on the blank;

[0038] D --- vertical side diameter after flanging;

[0039] Using ordinary punching method, punching single-side gap 0.05mm, the flanging coefficient of the material is between 0.7-0.8.

[0040] Adopt punching method of the present invention, process parameter is as follows:

[0041] Working power supply: single-phase 220V / 50Hz; working voltage range: 180V~250V; maximum input current: 20A; oscillation power: 2KVA; oscillation frequency: 100KHz.

[0042] The distance between the lower edge of the heat insulation layer of the punch ...

Embodiment 2

[0045] Embodiment 2: The sheet metal is a bainitic dual-phase steel, and its mechanical properties are as follows:

[0046] Yield strength: 345 MPa; ultimate strength: 556Mpa; elongation: 34%

[0047] Sheet thickness: 3mm; initial inner hole diameter on the blank: 10mm

[0048] Using ordinary punching method, punching single-side gap 0.06mm, the flanging coefficient of the material is between 0.6-0.65.

[0049] Adopt punching method of the present invention, process parameter is as follows:

[0050] Working power supply: single-phase 220V / 50Hz; working voltage range: 180V~250V; maximum input current: 30A; oscillation power: 5KVA; oscillation frequency: 80KHz.

[0051] The distance between the lower edge of the heat insulation layer and the bottom of the punch; S=6mm, the height of the heat insulation layer: 6mm, the thickness of the heat insulation layer: 3mm

[0052] The single-sided gap value of punching: C=0.02mm, keep warm for 10S after punching.

[0053] At this time,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com