Lower template of punching machine

A stamping machine tool and template technology, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems affecting production efficiency and continuous type, and achieve the effect of improving production efficiency, increasing continuous type, and convenient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described below in conjunction with accompanying drawing.

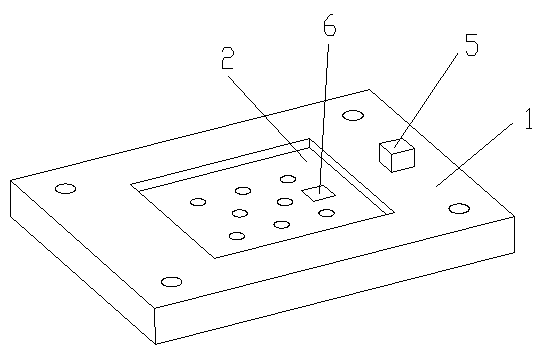

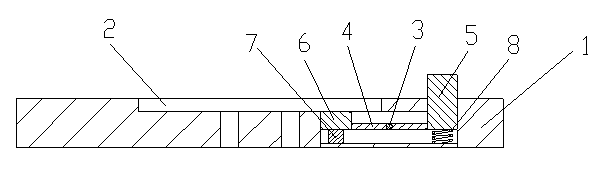

[0013] as attached figure 1 , 2 The shown lower formwork of a stamping machine tool according to the present invention includes a lower formwork body 1 and a stamping area 2; the center of the upper surface of the lower formwork body 1 is provided with a stamping area 2; stamping parts are placed in the stamping area 2 ; The inside of the lower template body 1 is provided with a lever mechanism for jacking up the stamping parts; the lever mechanism includes a rotating shaft 3, a support rod 4, a press block 5, a top block 6, a support seat 7 and a spring 8; The shaft 3 is arranged below the stamping area; the support rod 4 is arranged in the lower template body 1 through the rotating shaft 3; the press block 5 and the top block 6 are respectively arranged at both ends of the support rod 4; The lower part is provided with a spring 8; the upper surface of the press block 5 is higher tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com