Drive axle of articulated tractor

A technology for tractors and drive axles, applied in the field of machinery, can solve the problems affecting product quality and stability, output torque, and output speed fluctuations that are not stable enough to achieve compact structure, large input torque, and strong motion rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

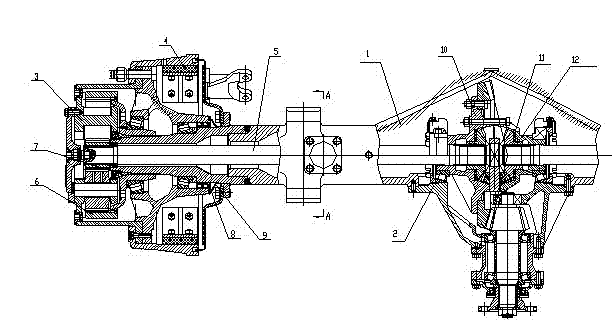

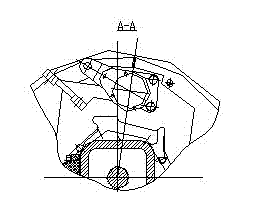

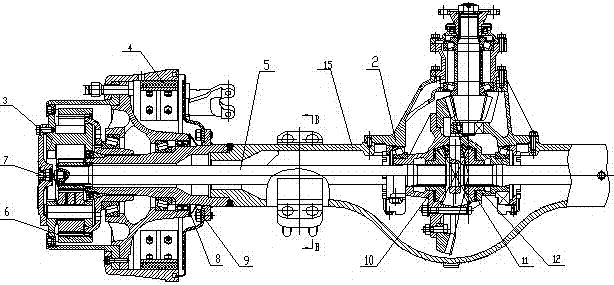

[0016] The structural scheme provided by the present invention is applicable to the front and rear drive axles of tractors, such as figure 1 , figure 2 Shown is a schematic diagram of the structure of the front drive axle housing, image 3 , Figure 4 Shown is a schematic diagram of the structure of the rear drive axle.

[0017] Taking the front drive axle housing as an example, the technical solution of the present invention is described in detail.

[0018] Such as figure 1 , figure 2 As shown, the front drive axle of the tractor includes a front drive axle housing assembly 1, a reducer assembly, a differential assembly 10 and a brake assembly 4. The reducer assembly is set as a two-stage reduction device, and the final reducer The assembly 2 and the wheel reducer assembly 3 are composed. The main reducer assembly 2 and the wheel reducer assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com