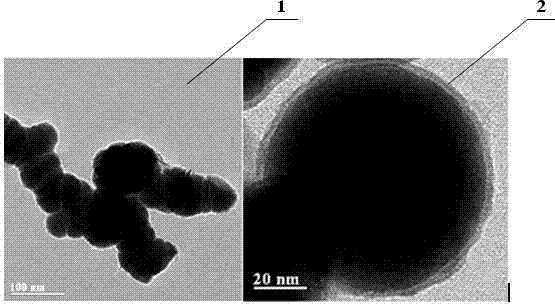

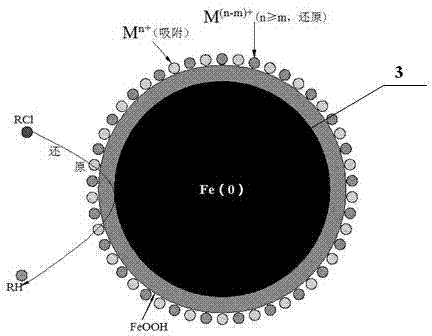

Method for removing harmful substances in sludge by using nano zero-valent iron

A nano-zero-valent iron and harmful substance technology, applied in the fields of sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Advanced problems, to achieve the effect of low cost, simple structure and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

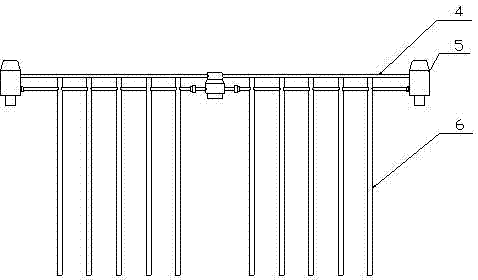

Method used

Image

Examples

Embodiment 1

[0040] The sludge is collected from anaerobic digestion sludge of a sewage treatment plant. The content of sulfide (hydrogen sulfide, methyl mercaptan, dimethyl sulfide, dimethyl disulfide) in the sludge is between 0.0001-0.00047 ppm. The pH is between 7.3-7.7. In this study, several sludge samples with the same sulfide content were designed, and the amount of nano-zero-valent iron was increased sequentially (0.5-5 kg). storage capacity. In order to make the experimental effect more obvious, the method of adding sulfide sludge was adopted. According to the process flow of this study, the water and the spiked sludge were mixed and stirred for 5-20 h in the mixing reaction device, and the sulfide sludge in the mixed liquid water and the sludge were respectively measured. For sulfide content, add different amounts of nanometer zero-valent iron, mix thoroughly for 1-3 hours, measure the pH and Eh of the reaction mixture, and fit the function of the pH and Eh of the solution with ...

Embodiment 2

[0042] The sludge is collected from an anaerobic digestion sludge of a sewage treatment plant. The metal (arsenic, cadmium, chromium, cobalt, copper, lead, manganese, mercury, nickel, molybdenum, selenium, titanium, zinc) content in the sludge is 0.1 -2000 mg / kg. This study is designed as two sludge samples with the same specific metal content (1000-2000 mg / kg). The same amount of nanometer zero-valent iron and micrometer zerovalent iron is added to the two samples. After the reaction is sufficient, the adsorption Metallic zero-valent iron is separated, and the removal rate of metals in sludge is determined. Here the amount of sludge is 500-1000 g and the volume of water is 5-10 L. According to the technological process of this study, the water and heavy metal-containing sludge were mixed and stirred for 5-20 h in the mixing reaction device, and the metal content in the mixed liquid water and sludge were respectively measured, and nano-sized zero-valent iron and micro-sized z...

Embodiment 3

[0044] The sludge was collected from anaerobic digested sludge of a sewage treatment plant, and the content of HCH in the sludge interstitial water was 600-800 μg / L. In this study, several sludge samples with specific content of organic pollutants (100-800 μg / L) were designed. Different amounts of nanometer zero-valent iron were added to these samples. Separation of zero-valent iron and determination of the removal rate of organic pollutants in sludge. In order to make the research effect more obvious, the method of adding standard organic pollutant sludge was adopted. According to the process flow of this research, the water and the spiked sludge were mixed and stirred for 5-20 h in the mixing reaction device, and the mixed liquid water and sludge were measured respectively. The content of organic pollutants, then 2-30 g / L nano-zero-valent iron, fully mixed for 2-50 h, and then the reaction system was separated from the sludge and nano-zero-valent iron through an electromagne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap