Hydraulic gadder and oil distribution sliding valve thereof

A technology for hydraulic rock drills and oil slide valves, which is applied to mechanical equipment, fluid pressure actuators, servo motor components, etc., and can solve the problem of easy jamming of the valve core 12, easy cracking of the right end surface of the valve core 12, and heating of the valve core 12, etc. problem, to prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

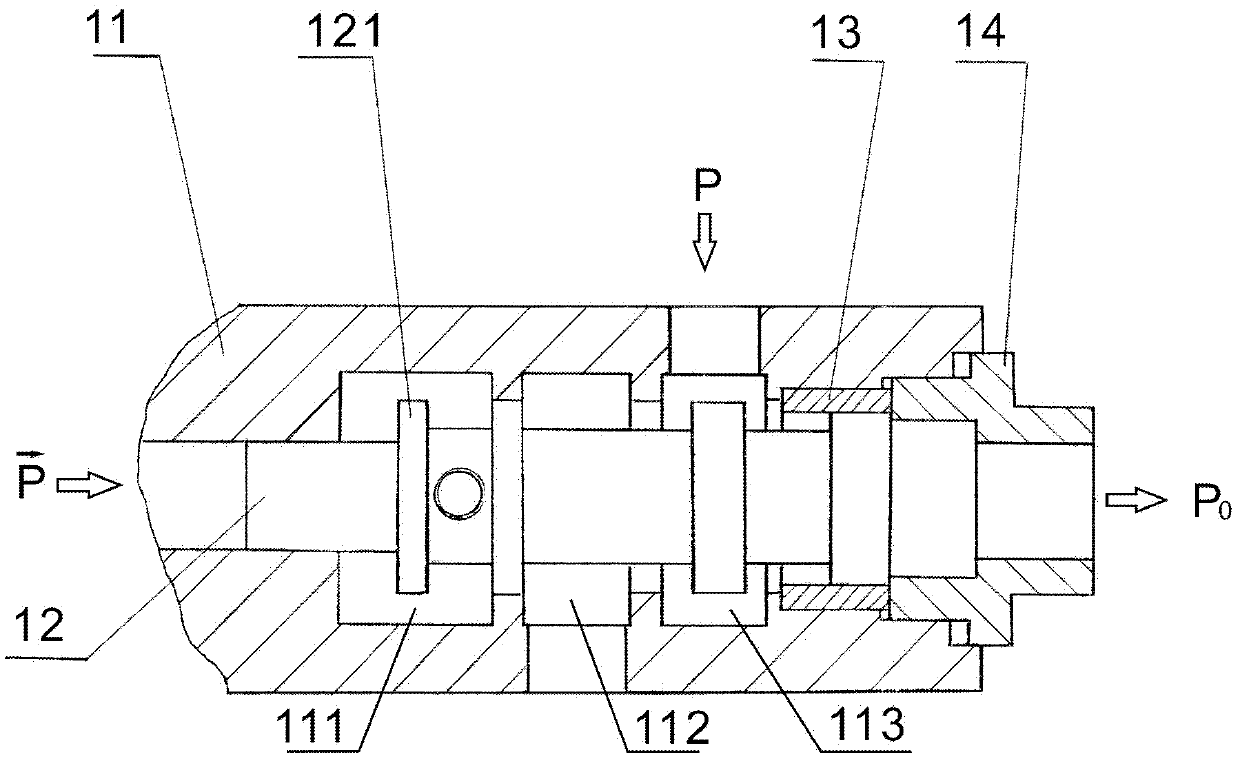

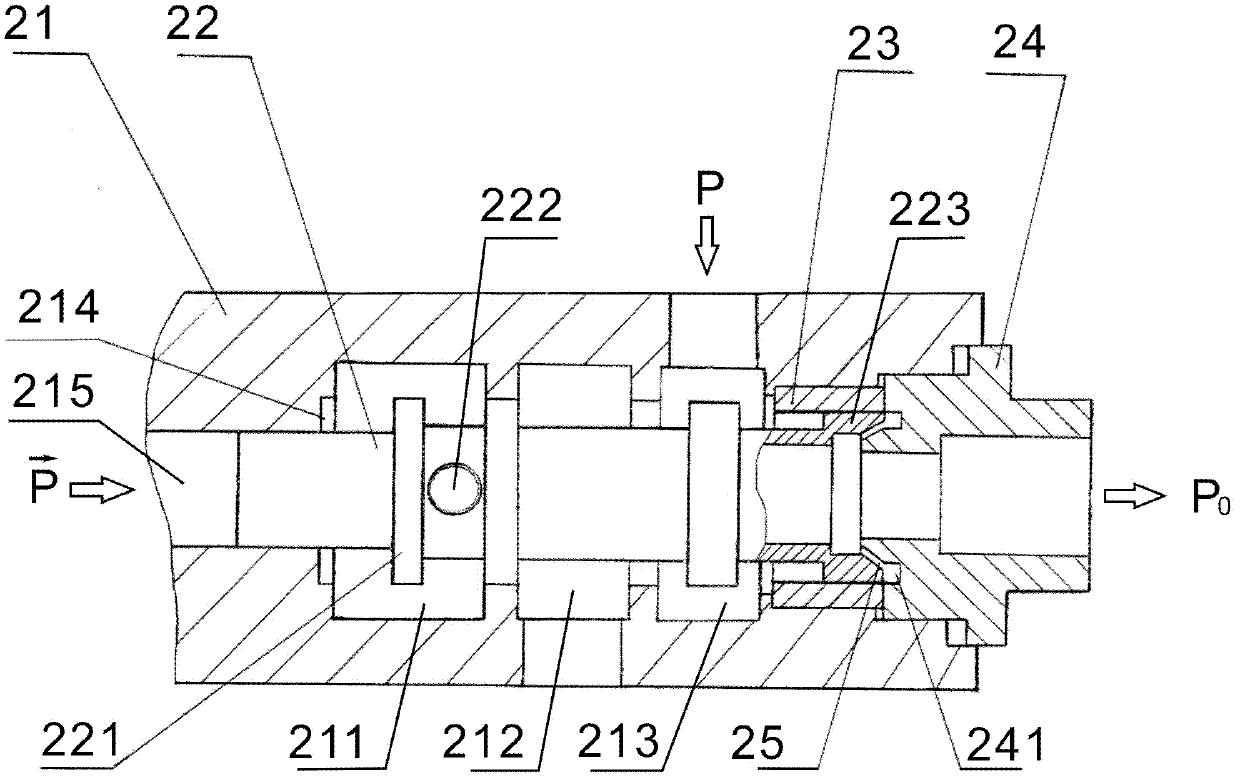

[0026] Please refer to figure 2 , an oil distribution slide valve of a hydraulic rock drill according to the present invention, comprising a valve body 21, a valve core 22, a valve sleeve 23 and a valve seat 24; the valve body 21 includes a signal input port 215, a low pressure chamber 211, an alternating chamber 212 and a normal pressure chamber 213, wherein the normal pressure chamber 213 communicates with the external hydraulic oil passage, the alternating chamber 212 communicates with the piston back chamber, and the low pressure chamber 211 communicates with the oil return passage; The left end of 22 is located in the signal input port 215, and there is a small gap between the hole wall of the signal input port 215, and the right end of the valve core 22 passes through the low-pressure chamber 211, the alternating chamber 212 and the normal-pressure chamber 213 successively, and then meets the valve seat. 24, the valve seat 24 is installed at one end of the valve body 21...

Embodiment 2

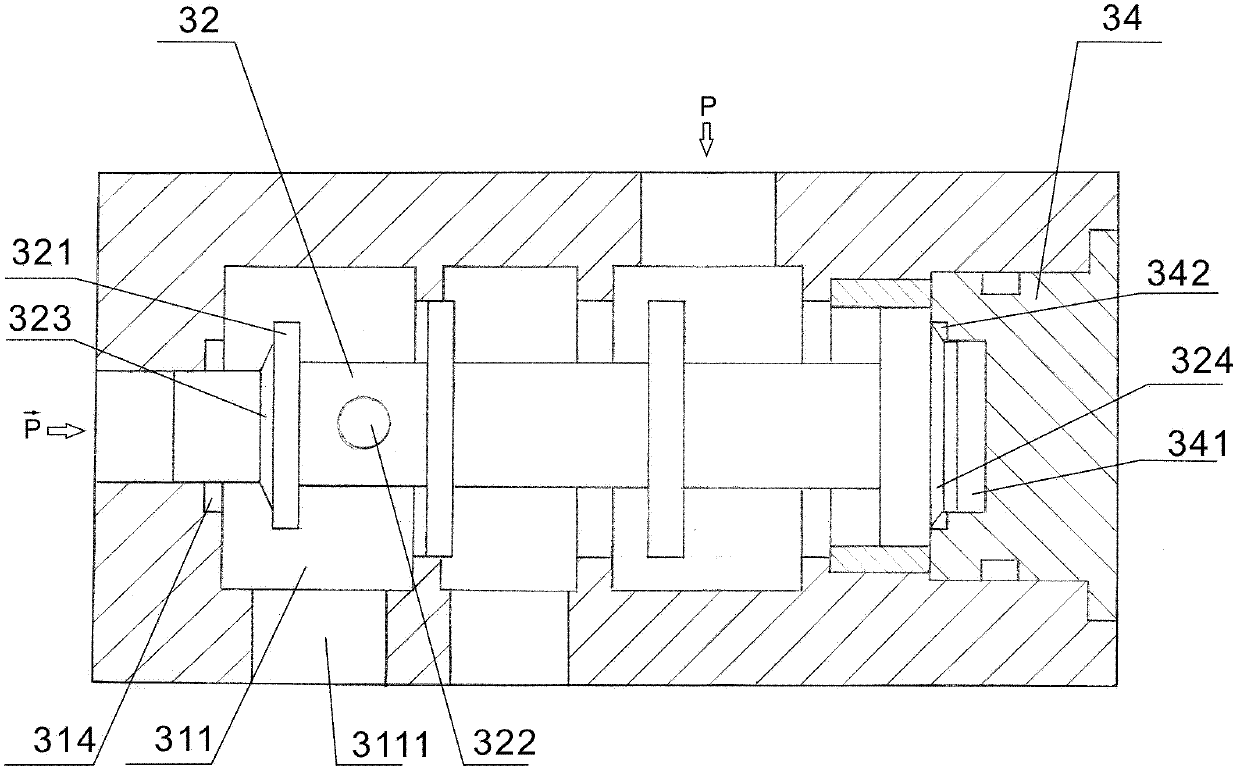

[0036] Please refer to image 3 and Figure 4 , the second embodiment of the oil distribution slide valve of a hydraulic rock drilling machine of the present invention is basically the same as the first embodiment in the working principle, basic structure, and deceleration principle of the oil distribution slide valve.

[0037] The difference of this example from Example 1 lies in the replacement of local structures, including:

[0038] The low-pressure chamber 311 communicates with the oil return passage through the channel 3111. The middle part of the valve seat 34 is provided with a stepped hole, and the part of the valve core 32 located in the low-pressure chamber 311 is provided with a round hole 322. 34 connected. The shape of the first buffer chamber 314 is the same as that of the first embodiment, and its size is slightly smaller than the shoulder boss 321 of the valve core 32. The shoulder boss 321 is provided with a conical surface 323 matching the first buffer cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com