Assembly structure of sheet metal parts for vehicles

A technology for assembling structures and sheet metal parts. It is applied in the direction of connecting components, bolts, and mechanical equipment. It can solve the problems of easy-wearing hexagonal head edges, bolt tooth extraction, wire marking, and increased assembly processes, so as to achieve low manufacturing costs and avoid Incorrect direction of rotation, effect of effective stop action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below by embodiment, in conjunction with accompanying drawing, the present invention is described in further detail:

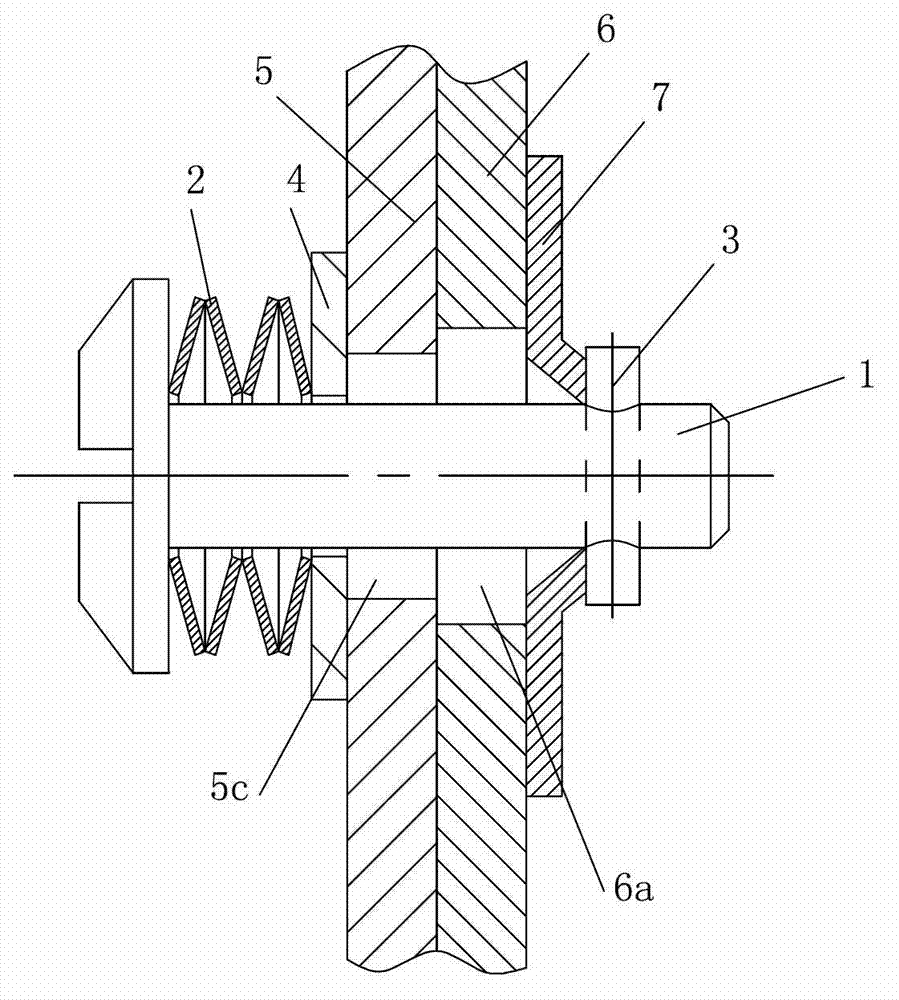

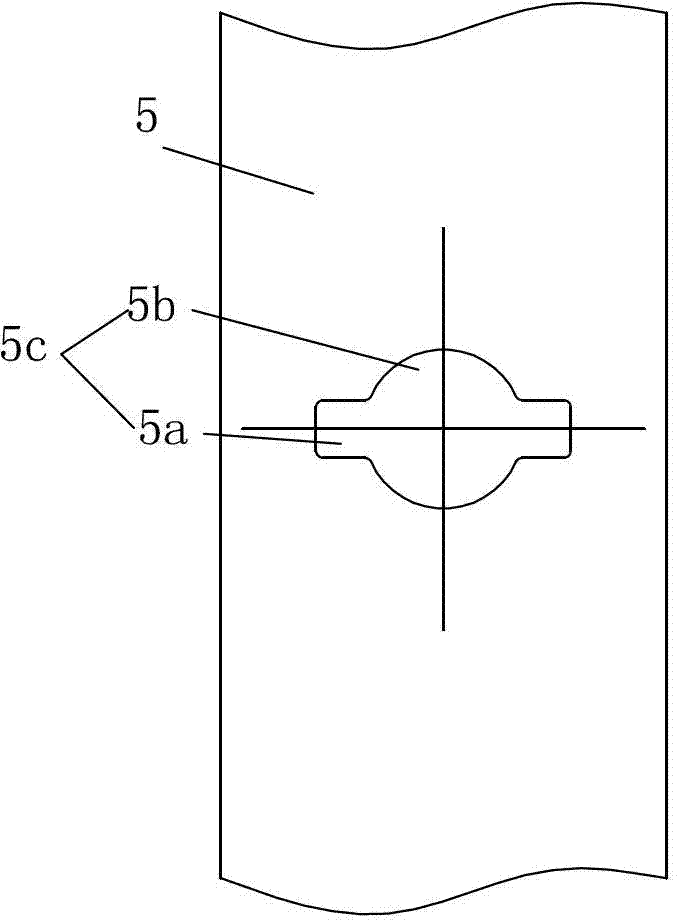

[0027] Such as figure 1 The assembly structure of the vehicle sheet metal parts shown is composed of the first sheet metal part 5, the second sheet metal part 6, the positioning plate 7 and the fastening connection assembly. The fastening connection assembly consists of a connecting rod 1, a return spring 2 , Limiting pin 3 and flat pad 4 are formed.

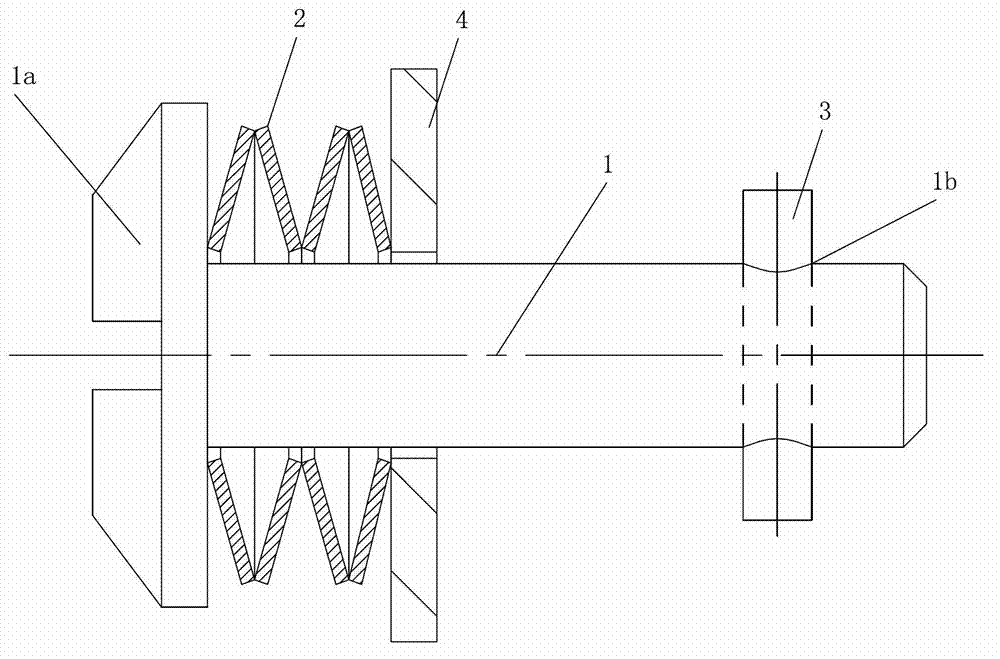

[0028] Such as figure 2 As shown, the connecting rod 1 has an end 1a, the return spring 2 and the flat pad 4 are sequentially set on the connecting rod 1, and a pin through hole 1b is arranged at the lower end of the rod part of the connecting rod 1, and the limit pin 3 is inserted in the pin passing through hole 1b. In the hole 1b and fixedly connected with the connecting rod 1. The return spring 2 and the flat washer 4 are located between the end 1a of the connecting rod 1 and the pin through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com