Rotary tillage full-thickness fertilizer applying machine

A full-layer fertilization and rotary tiller technology, which is applied to agricultural machinery and implements, shovels, plows, etc., can solve the problems of uneven distribution of fertilizers in the field, and achieve the goal of improving fertilizer utilization, operating efficiency, and evenness of fertilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

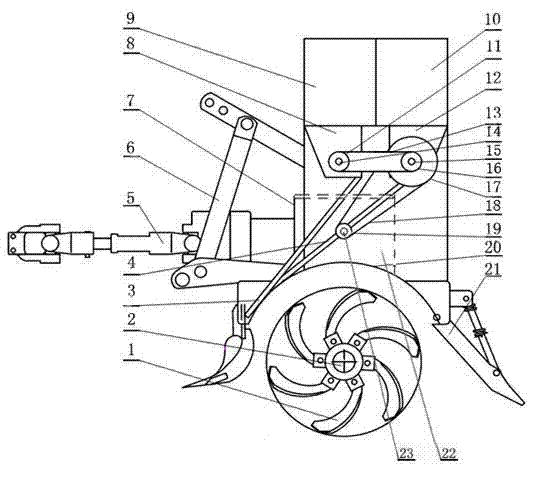

[0011] exist figure 1 Among them, the rotary tillage full-layer fertilizer applicator is provided with a main body frame 6 carrying various components, the middle part of the frame 6 is connected with a gear box 7, and the front part of the gear box 7 is connected with the universal joint 5, and through the universal joint 6 Connect with the motor, input power, the bottom of the gearbox 7 is connected with the rotary tiller shaft 2, and the arc-shaped rotary tiller 1 is installed on the rotary tiller shaft 2; the side of the frame 6 is assembled and connected with the soil cover 21 and the upper cover Plate 20, the upper cover plate 20 can prevent the soil rolled up when the rotary tiller 1 rotates the land, and the both sides of the frame 6 are provided with plate-shaped support plates 22, and the top of the support plates 22 is connected with a square-shaped compound fertilizer. Case 9 and nitrogen chemical fertilizer case 10, the bottom of compound fertilizer case 9 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com