Recovering system of single type tobacco stem and shred online separating

A technology of cigarette making machine and shredded tobacco, which is applied in the direction of solid separation, separation of solids from solids by airflow, and tobacco, etc. It can solve the problems of moisture and aroma loss of shredded tobacco, downgrading of high-grade shredded tobacco, waste of resources and economic losses, etc., and achieve reduction Tobacco consumption, simple and compact structure, and the effect of reducing logistics costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

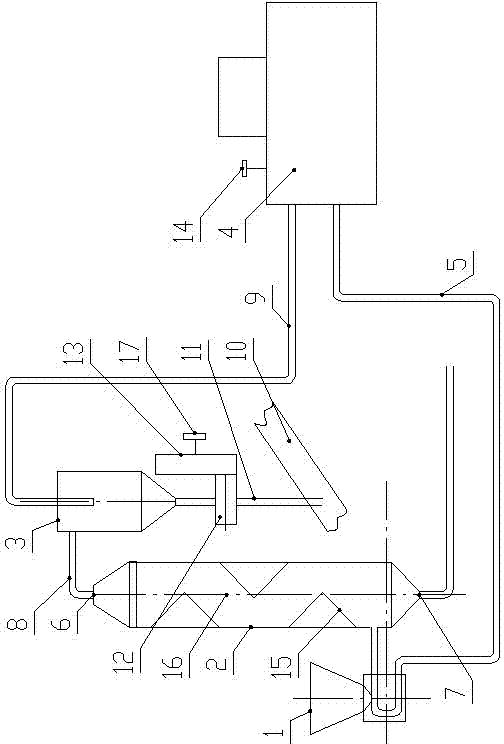

[0015] Such as figure 1 As shown, the on-line separation and recovery system of tobacco stems and shredded tobacco of the present invention includes a receiving hopper 1, a tower separator 2, a cyclone separator 3 and a blower 4, and the blower port of the blower 4 passes through the blowing pipe 5 is connected to the lower side of the tower separator 2, the outlet of the hopper 1 is set on the blowing pipe 5, and the top and bottom of the tower separator 2 are respectively provided with a shredded tobacco outlet 6 and a tobacco stem outlet 7. The shredded tobacco discharge port 6 is connected to the feed port of the cyclone separator 3 through a pipe 8. The top and bottom of the cyclone separator 3 are respectively provided with a suction port and a discharge port. The air duct 9 is connected with the suction port of the cyclone separator 3 .

[0016] The feeding port of the cyclone separator 3 is connected with a feeding pipe 11, and the lower end of the feeding pipe 11 ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com