Device for rapidly detaching drill bit of drilling machine

A drill bit and drilling machine technology, applied in positioning devices, tool joints, clamping, etc., can solve problems such as unfavorable assembly line production, affecting production tempo, unsafety, etc., and achieve the goal of increasing effective working time, saving auxiliary time, and reducing labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the present invention is described in further detail:

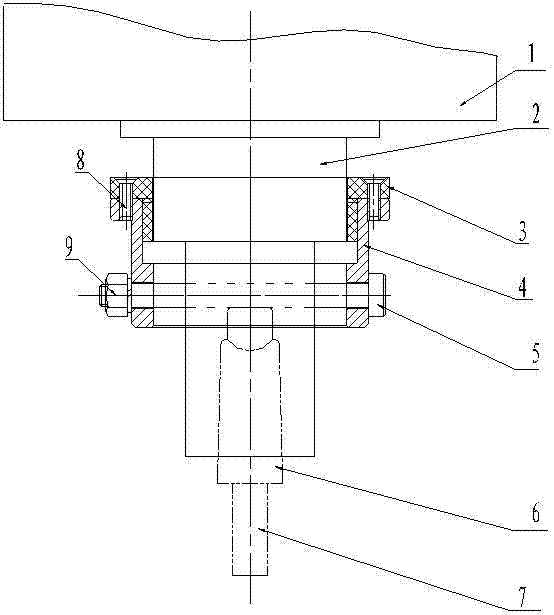

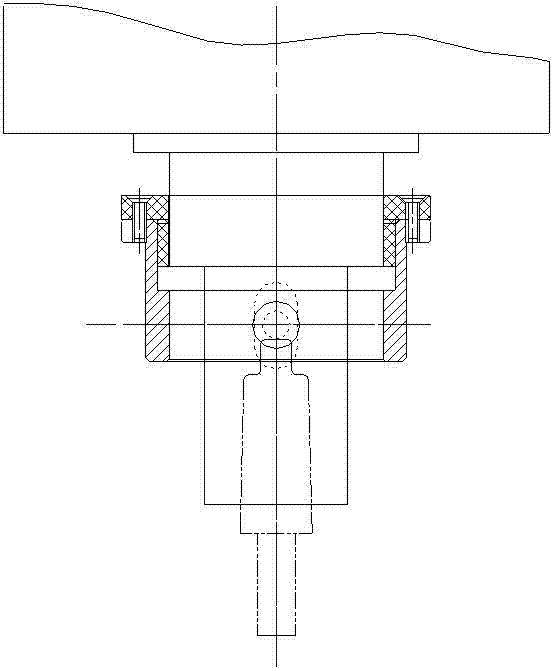

[0011] like figure 1 Shown: A quick-release drill bit device for a drilling machine, which includes: a machine bed 1, a main shaft 2, a nylon sleeve 3, a sleeve 4, a pin shaft 5, a drill sleeve 6, a drill bit 7, screws 8 and nuts 9, on the machine bed 1 A main shaft 2 is provided, a drill sleeve 6 is embedded in the main shaft 2, a drill bit 7 is arranged in the drill sleeve 6, and the sleeve 4 is inserted into the main shaft 2 and connected with the pin shaft 5 through the waist-shaped hole of the main shaft 2, see figure 2 , the top of the pin shaft 5 is stuck on the outer surface of the sleeve 4, and the other end is fastened with a nut 9. A nylon sleeve 3 is installed in the gap between the sleeve 4 and the main shaft 2. The function of the nylon sleeve 3 is to ensure that the sleeve 4 is up and down The main shaft 2 will not be pulled when moving, and both ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com