Angle-adjustable fixture for machine tool

An adjustable, angled technology used in clamping, manufacturing tools, metalworking machine parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

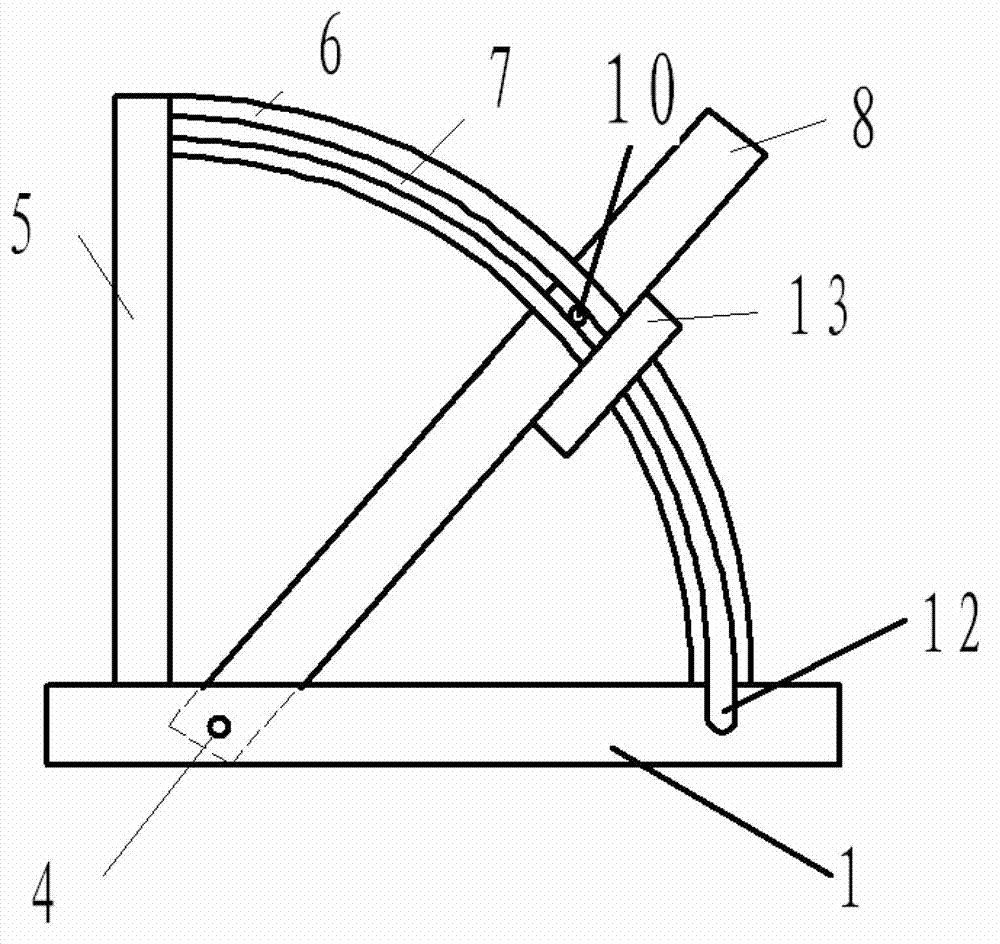

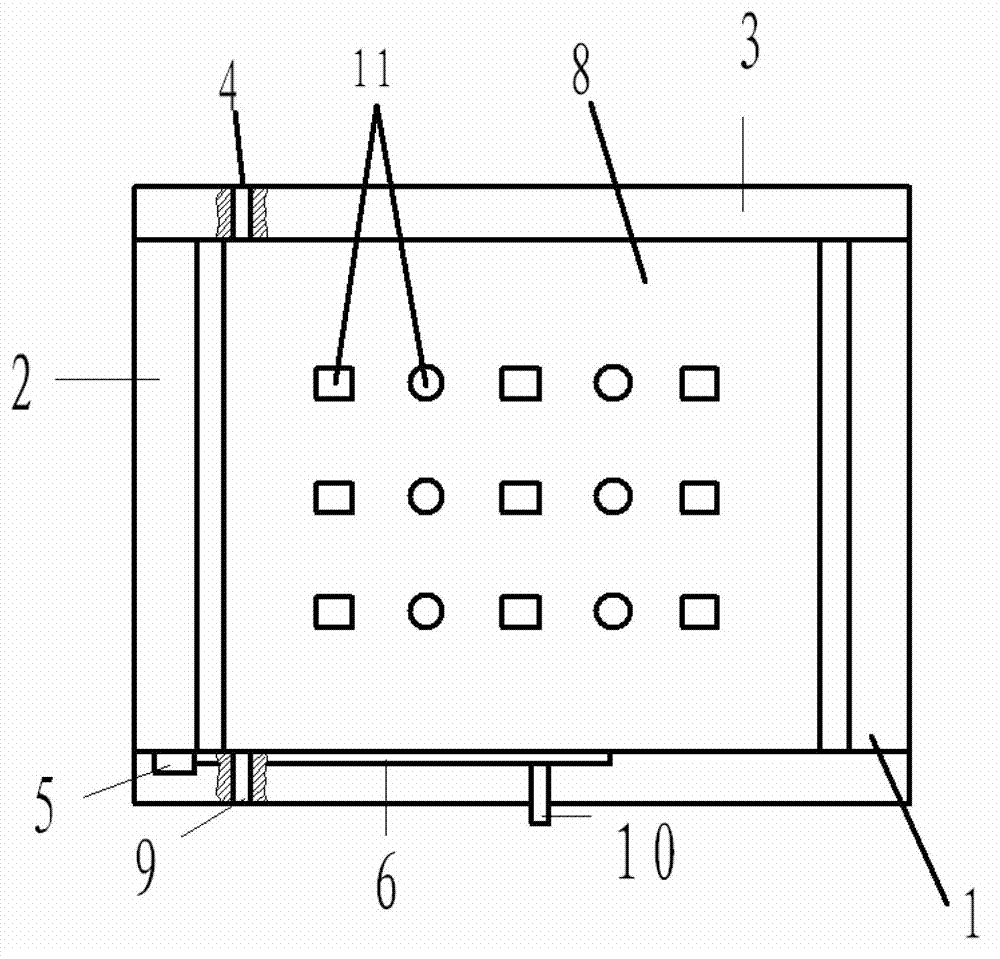

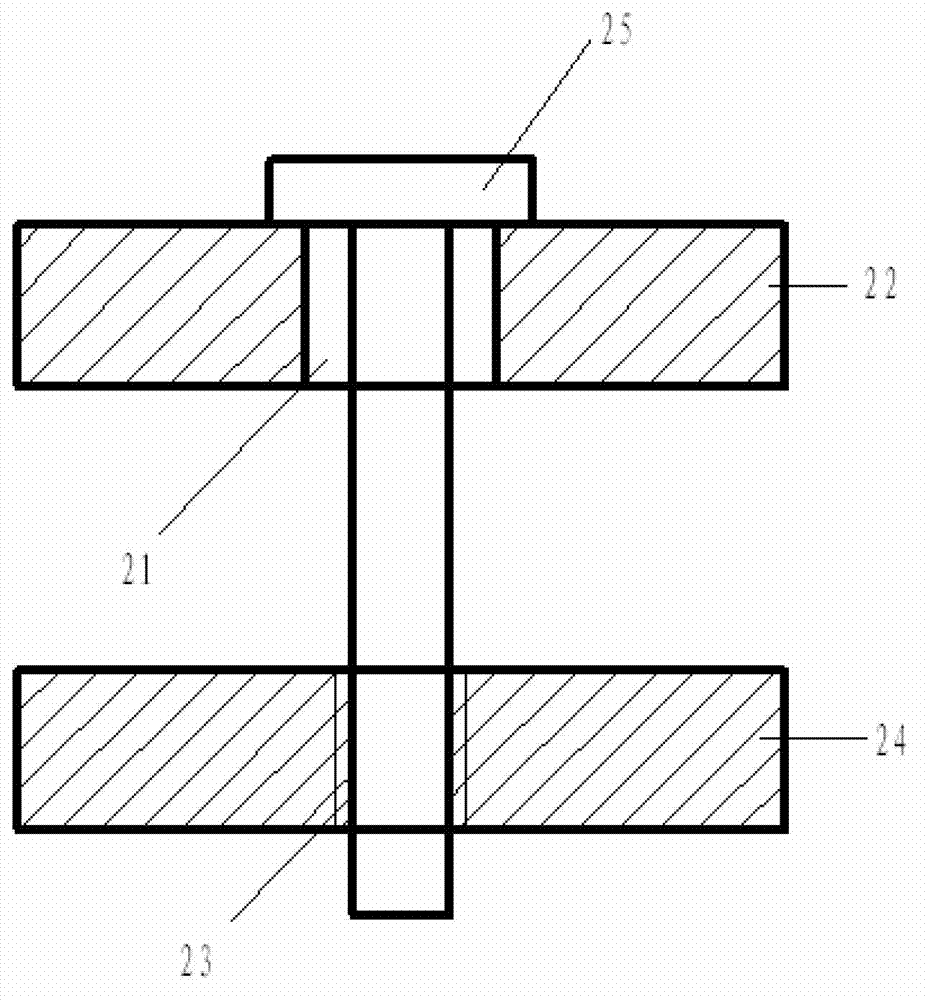

[0020] A kind of specific embodiment of the present invention is described below in conjunction with accompanying drawing, as figure 1 and figure 2 As shown, the present invention includes: a base 1, which can be stably fixed on the machining table of the machine tool. The base 1 is composed of two beams 2 and two plates 3 fixedly connected. Two holes 4 are symmetrically arranged at one end of the two plates 3 , and a support plate 5 is fixedly arranged on the same end of one of the plates 3 . An arc-shaped bracket 6 is provided, the two ends of which are fixedly connected with the plate 3 and the support plate 5 respectively, and an arc-shaped channel 7 is arranged in the arc-shaped bracket 6 . The base 1 is provided with a rotating plate 8, and one end of the rotating plate 8 is symmetrically provided with two shafts 9 installed in the two holes 4, so that it can rotate but cannot produce lateral and longitudinal displacement. A force applying rod 10 is arranged on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com