Self-pressurizing bidirectional balancing buffer device for press machine

A technology of buffering device and balancing device, applied in the direction of presses, manufacturing tools, etc., can solve the problems of incompatibility of large-scale fast presses, small inertial impact and balance effect, affecting the normal use of equipment, etc., to improve the manual operation environment, The effect of reducing inertial shock and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

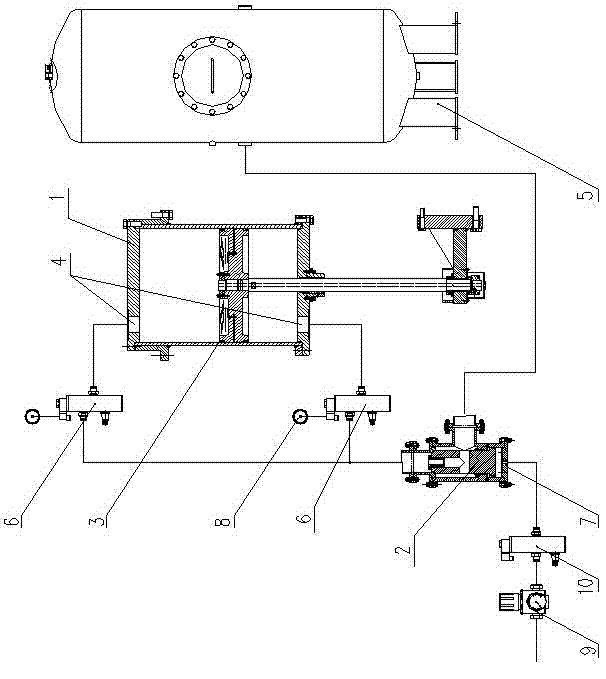

[0013] Such as figure 1 As shown, the self-boosting two-way balance buffer device of the press includes a two-way balancing device 1 and a self-boosting device 2. The pressure device 2 is connected through the air pipe; the two-way balance device 1 includes a balance cylinder 3 and an air storage tank 5, and the free end of the piston rod of the balance cylinder 3 is connected with the slide block of the corresponding press, and at the ends of the two ends of the balance cylinder 3 Air holes 4 are respectively arranged on the cover, and the air outlet of the air storage tank 5 communicates with the air holes 4 at both ends of the balance cylinder 3 through the air pipe, and an electromagnetic valve 6 is respectively set on the air pipe communicated with the rod chamber and the rodless chamber of the balance cylinder 3. Self-supercharging device 2 comprises boosting valve 7, and boosting valve 7 is arranged between air storage tank 5 and balance cylinder 3, and the air inlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com