Production process of combined stereoscopic embroidery

A technology of three-dimensional embroidery and production process, applied in the direction of embroidery machine mechanism, embroidery machine, decorative arts, etc., can solve the problems such as can not meet the needs of the market, the three-dimensional effect is not obvious, and the color is single, so as to broaden the field of innovative embroidery, enrich the Embroidery skills, strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

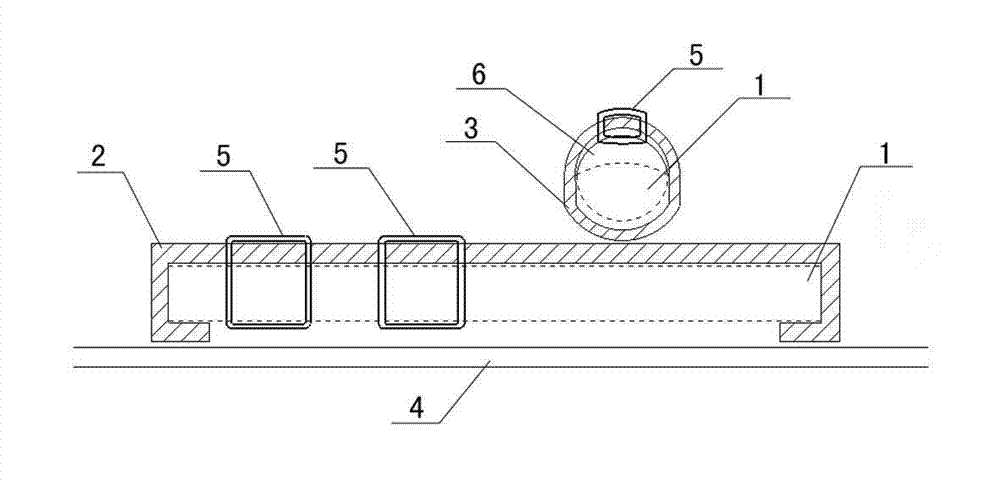

[0017] A manufacturing process for combined three-dimensional embroidery, comprising the following steps: a. stacking four layers of white cotton cloth as base material 1 and bonding them together with batter; b. Put the bonded white cotton cloth (substrate fabric 1) and cut out the base fabric layer of the embroidery in the shape of a tiger outline, and leave the leftovers; c. Use batter on the edges of the upper surface, side and bottom of the base fabric layer of the embroidery Bonding and covering a layer of yellow silk cloth (surface layer fabric 2); d. performing drag embroidery on the upper surface of the silk cloth (surface layer fabric 2) to form a tiger pattern (except for the tiger's nose); e. embroidering the tiger pattern In front of the nose, cut out three circular samples of the same size as the tiger's nose with leftover material, stack the three circular samples and glue them together with paste, lay cotton 6 on the upper surface of the uppermost circular sampl...

Embodiment 2

[0020] A manufacturing process for combined three-dimensional embroidery, comprising the following steps: a. stacking three layers of cotton linen cloth as the base material 1 and bonding them together with paste; b. according to the pre-designed size and shape, Lay and bond the cotton linen cloth (substrate fabric 1) and cut out the embroidery base fabric layer in the shape of a rabbit outline, leaving the leftovers; c. Then wrap a layer of white cotton cloth (surface layer fabric 2); d. Perform drag embroidery on the upper surface of the white cotton cloth (surface layer fabric 2) to form a rabbit pattern (except for the eyes of the rabbit); e. Before the eyes of the embroidered rabbit pattern, Cut out four circular samples with the same size as the eyes of rabbits with leftover materials, stack the four circular samples and glue them together with paste, and lay cotton on the upper surface of the uppermost circular sample to form a support. Blue silk cloth (outer layer of f...

Embodiment 3

[0022] A manufacturing process for combined three-dimensional embroidery, comprising the following steps: a. stacking two layers of white cotton cloth as the base material 1 and bonding them together with paste; b. according to the pre-designed size and shape, Lay and bond the white cotton cloth (substrate fabric 1) and cut out the base fabric layer of the embroidery in the shape of the outline of the faucet, leaving the leftovers; c. Then wrap a layer of green silk cloth (surface layer fabric 2); d. Perform drag embroidery on the upper surface of the silk cloth (surface layer fabric 2) to form a dragon head pattern (except for the eyes of the dragon head); e. Embroider the eyes of the dragon head pattern Beforehand, cut out five circular samples with the same size as the eyes using leftover materials, stack the circular samples and glue them together with batter, and lay cotton on the upper surface of the uppermost circular sample to form a support. The linen cloth (outer lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com